Method for preparing mesoporous boron nitride by urea-assisted heat peeling of boron nitride

A technology of boron nitride and auxiliary heat, applied in chemical instruments and methods, nitrogen compounds, alkali metal oxides/hydroxides, etc. High adsorption performance of boron and other problems, to achieve good innovation and application prospects, simple process, low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

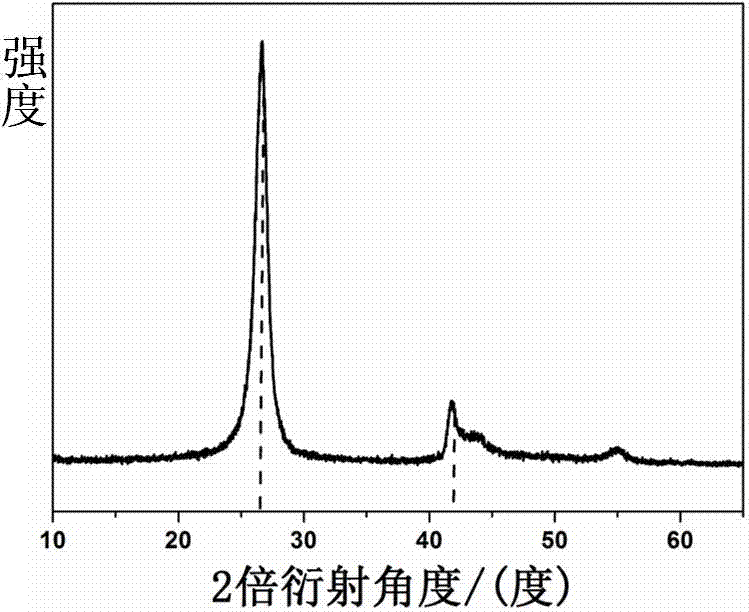

[0035] Such as figure 1 As shown, a method for preparing mesoporous boron nitride by urea-assisted thermal exfoliation of boron nitride The specific preparation method includes the following:

[0036] Step 1: Grind 8 g of urea and 24 g of boron trioxide in an agate mortar for 30 minutes to mix them evenly.

[0037] The second step: put the uniformly mixed urea-boron trioxide mixture in the alumina crucible, and cover the crucible lid.

[0038] Step 3: Put the crucible in a vacuum atmosphere furnace, raise the temperature to 1100°C at a rate of 10°C / min, keep the temperature for 4 hours and then cool down to room temperature naturally.

[0039] Step 4: Take out the sample and wash it 5 times with deionized water to remove unreacted boron trioxide.

[0040] Step 5: Put the treated sample in an oven at 100°C to dry for 12 hours, take out the dried sample and grind it into powder in a mortar, and the obtained sample is a white boron nitride powder material.

[0041] Step 6: Gri...

Embodiment 2

[0047] Such as figure 1 As shown, a method for preparing mesoporous boron nitride by urea-assisted thermal exfoliation of boron nitride The specific preparation method includes the following:

[0048] Step 1: Grind 8 g of urea and 32 g of boron trioxide in an agate mortar for 20 minutes to mix them evenly.

[0049] The second step: put the uniformly mixed urea-boron trioxide mixture in the alumina crucible, and cover the crucible lid.

[0050] Step 3: Then put the crucible in a vacuum atmosphere furnace, raise the temperature to 1100°C at a rate of 10°C / min, keep the temperature for 4 hours and then cool down to room temperature naturally.

[0051] Step 4: Take out the sample and wash it 3 times with deionized water to remove unreacted boron trioxide.

[0052] Step 5: Put the treated sample in an oven at 100°C to dry for 12 hours, take out the dried sample and grind it into powder in a mortar, and the obtained sample is a white boron nitride powder material.

[0053] Step 6...

Embodiment 3

[0059] A method for preparing mesoporous boron nitride by urea-assisted thermal exfoliation of boron nitride The specific preparation method comprises the following steps:

[0060] Step 1: Grind 8 g of urea and 32 g of boron trioxide in an agate mortar for 30 minutes to mix them evenly.

[0061] The second step: put the uniformly mixed urea-boron trioxide mixture in the alumina crucible, and cover the crucible lid.

[0062] Step 3: Then put the crucible in a vacuum atmosphere furnace, heat up to 1000°C at a rate of 10°C / min, keep the temperature for 3 hours and then cool down to room temperature naturally.

[0063] Step 4: Take out the sample and wash it 4 times with deionized water to remove unreacted boron trioxide.

[0064] Step 5: Put the treated sample in an oven at 100°C to dry for 12 hours, take out the dried sample and grind it into powder in a mortar, and the obtained sample is a white boron nitride powder material.

[0065] Step 6: Grind 0.25g of boron nitride and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com