Automobile coating wastewater treatment process and automobile coating wastewater treatment system

A technology for painting wastewater and treatment process, which is applied in the field of automobile painting wastewater treatment process and automobile painting wastewater treatment system, and can solve the problems of complex structure and inconvenient automobile painting wastewater treatment, investment and operation of automobile painting wastewater treatment system High cost and other issues, to achieve good sewage purification effect, good social and economic benefits, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

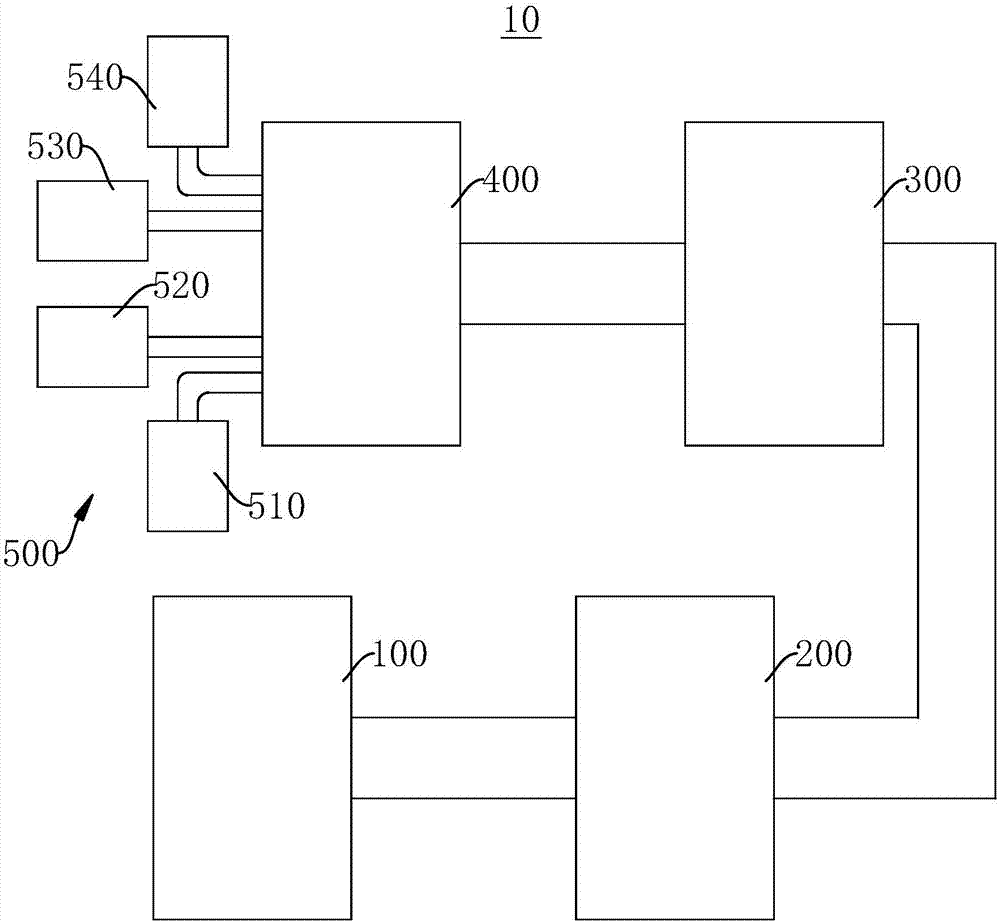

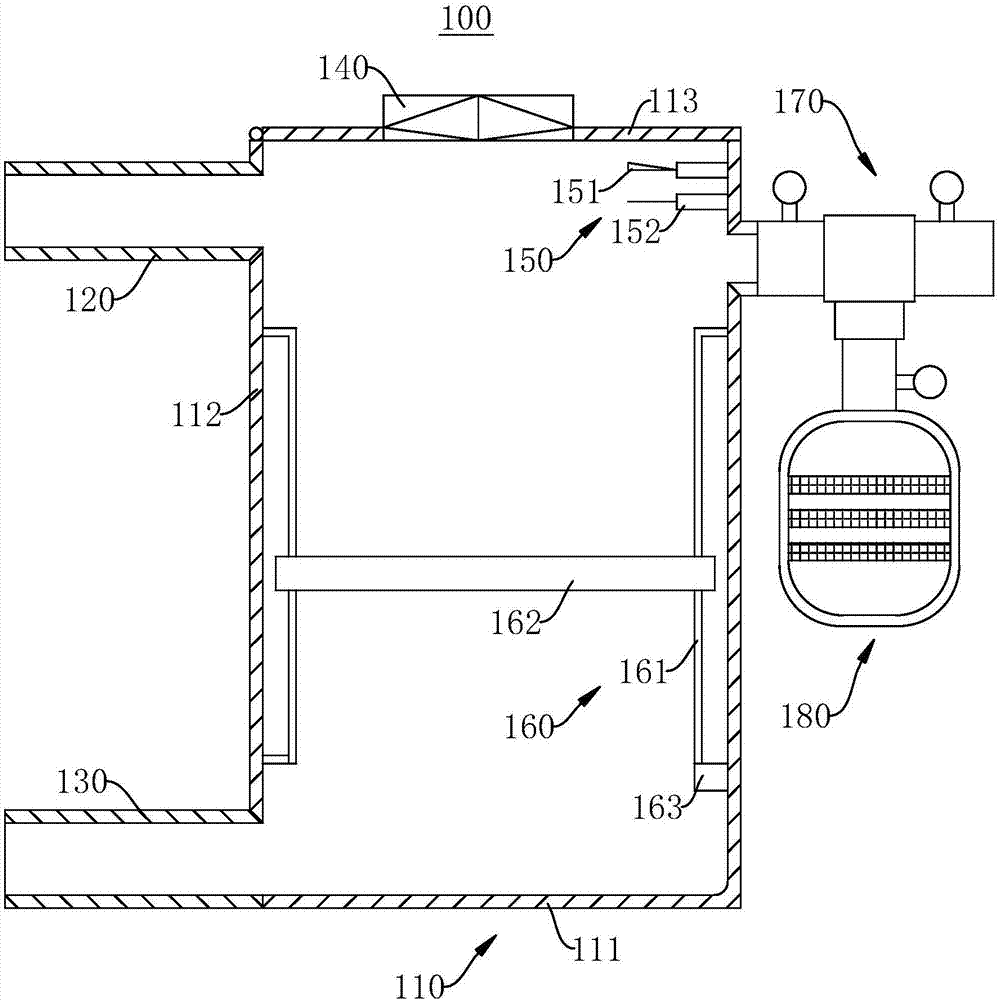

[0034] see figure 1 , the present embodiment provides an automobile painting wastewater treatment system 10, which has a simple structure and a good sewage purification effect. At the same time, it has the characteristics of small footprint, low investment and operating costs, convenient operation and management, and has good social and economic benefits.

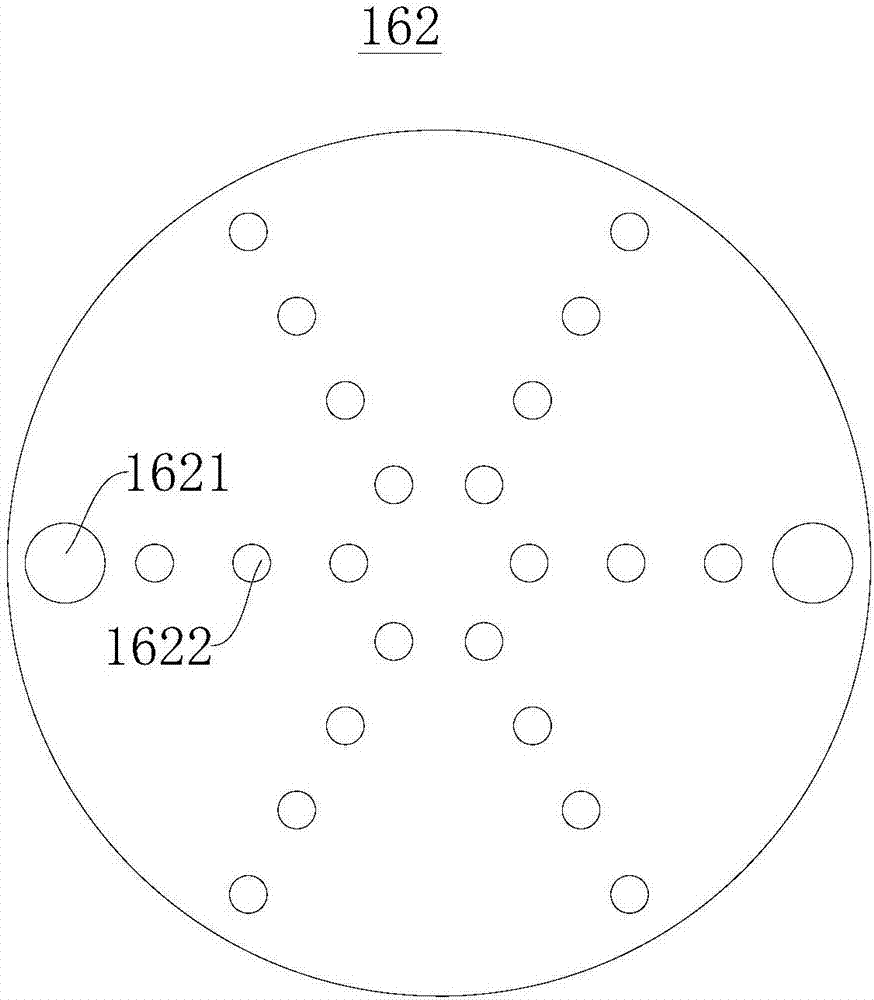

[0035] The automobile painting wastewater treatment system 10 provided in this embodiment includes a pretreatment system 500 , a coagulation reaction tank 400 , an inclined tube sedimentation tank 300 , a hydrolysis tank 200 and a biological filter tank 100 .

[0036] The pretreatment system 500 provided in this embodiment is connected to the coagulation reaction tank 400, the coagulation reaction tank 400 is connected to the inclined tube sedimentation tank 300, the inclined tube sedimentation tank 300 is connected to the hydrolysis tank 200, and the hydrolysis tank 200 is connected to the biofilter 100 .

[0037] It can...

no. 2 example

[0068] This embodiment provides a process for treating automobile painting wastewater, which is used to treat automobile painting wastewater. The steps are simple and the sewage purification effect is good. At the same time, it has good social and economic benefits.

[0069] The automobile painting wastewater treatment process provided in this embodiment is carried out by using the automobile painting wastewater treatment system 10 provided in the first embodiment.

[0070] The automobile painting wastewater treatment process provided in this embodiment includes: a pretreatment step, a coagulation reaction step, a precipitation removal step, a hydrolysis acidification step and a molecular decomposition step.

[0071] Pretreatment steps: degreasing the degreasing wastewater, precipitating the phosphating and passivating wastewater, precipitating the electrophoresis wastewater and pretreating the painting wastewater, and treating the degreasing wastewater, phosphating and passi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com