Crop straw-based water retention type multi-nutrient element biodegradable high-molecular sustained and controlled release fertilizer

A technology of crop straw and slow-release fertilizer, which is applied in the direction of matrix fertilizer, urea compound fertilizer, nitrogen fertilizer, etc., can solve the problems of waste of environmental resources, air pollution, etc., achieve low cost, simple and effective preparation process, and improve crop quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] A method for preparing water-absorbing and water-retaining multi-nutrient element biodegradable polymer slow-controlled release fertilizer, comprising the following steps:

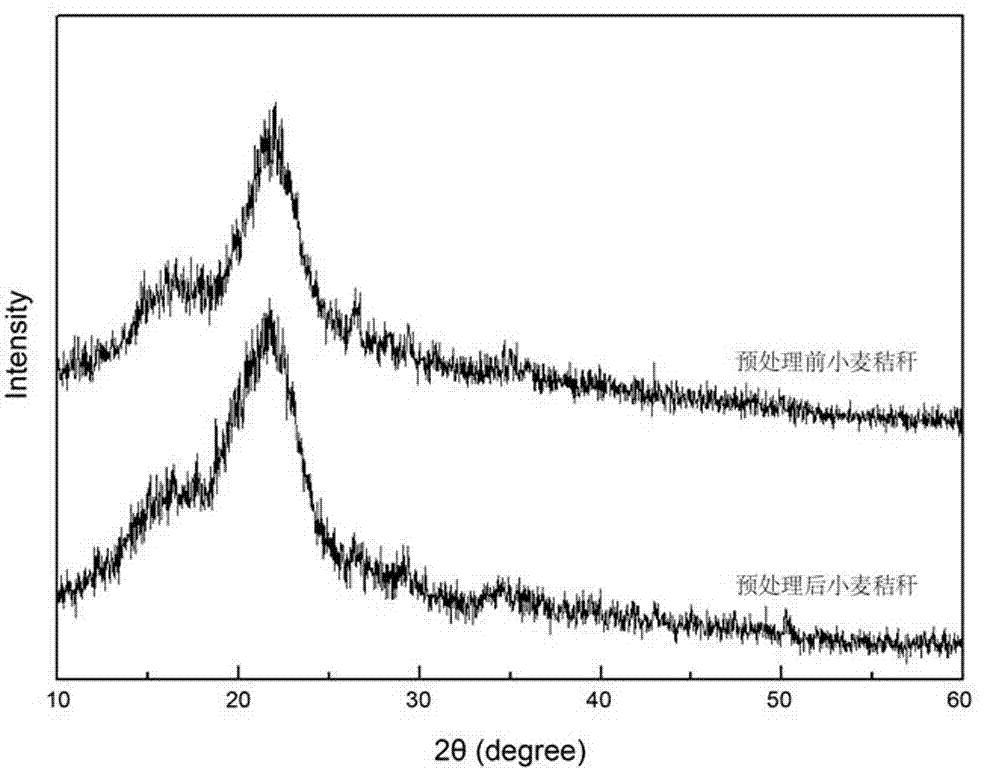

[0045] (1) Pretreatment of crop straw: Weigh crop straw powder, immerse in distilled water, filter after soaking at 60°C for 12h, place the filtrate in a mixture of 24% KOH and 1% NaBH 4 Stir in the formed solution for 3 hours and then filter, then repeatedly rinse the filtrate with distilled water until the filtrate is neutral, and dry it for later use;

[0046] (2) Add formaldehyde and urea respectively to the first reactor, use 5% KOH solution to adjust the system pH=8, and react at 40°C for 2 hours to obtain a methylolurea solution;

[0047] (3) In the second reactor, add acrylic acid, acrylamide and the pretreated crop stalk powder in step (1), and add a KOH solution with a mass fraction of 20% to adjust the neutralization degree of the acrylic acid monomer to be 20% to 20%. 100%; then add pot...

Embodiment 1

[0057] A method for preparing crop straw-based water-absorbing and water-retaining multi-nutrient element biodegradable polymer slow-controlled release fertilizer, comprising the following steps:

[0058] (1) Pretreatment of crop straw: Weigh crop straw powder, immerse in distilled water, filter after soaking at 60°C for 12h, place the filtrate in a mixture of 24% KOH and 1% NaBH 4 The resulting solution was stirred for 3 hours and then filtered, and then the filtrate was repeatedly washed with distilled water until the filtrate was neutral, and dried for later use.

[0059] (2) Add 6.70 g of formaldehyde and 6 g of urea to the first reaction vessel, adjust the pH of the system to 8 with 5% KOH solution, and react at 40° C. for 2 h to obtain a methylol urea solution.

[0060] (3) Add 5g of acrylic acid, 2g of acrylamide and 0.7g of the crop stalk powder treated in step (1) to the second reaction vessel, and add a KOH solution with a mass fraction of 20% to adjust the neutraliz...

Embodiment 2

[0064] A method for preparing crop straw-based water-absorbing and water-retaining multi-nutrient element biodegradable polymer slow-controlled release fertilizer, comprising the following steps:

[0065] (1) Pretreatment of crop straw: Weigh crop straw powder, immerse in distilled water, filter after soaking at 60°C for 12h, place the filtrate in a mixture of 24% KOH and 1% NaBH 4 The resulting solution was stirred for 3 hours and then filtered, and then the filtrate was repeatedly washed with distilled water until the filtrate was neutral, and dried for later use.

[0066] (2) Add 4.06 g of formaldehyde and 6 g of urea to the first reaction container, adjust the pH of the system to 8 with 5% KOH solution, and react at 40° C. for 2 hours to obtain a methylolurea solution.

[0067] (3) In the second reaction vessel, add 5.6g acrylic acid, 1.4g acrylamide and 0.7g step (1) in the processed crop stalk powder, and add the KOH solution that mass fraction is 20% to adjust the neutr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

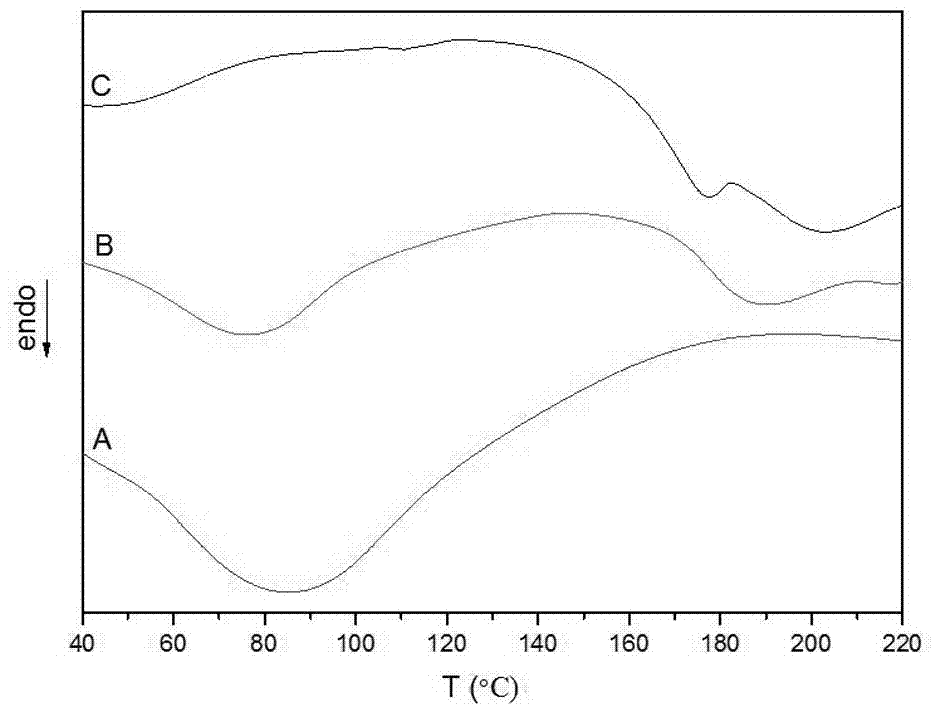

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com