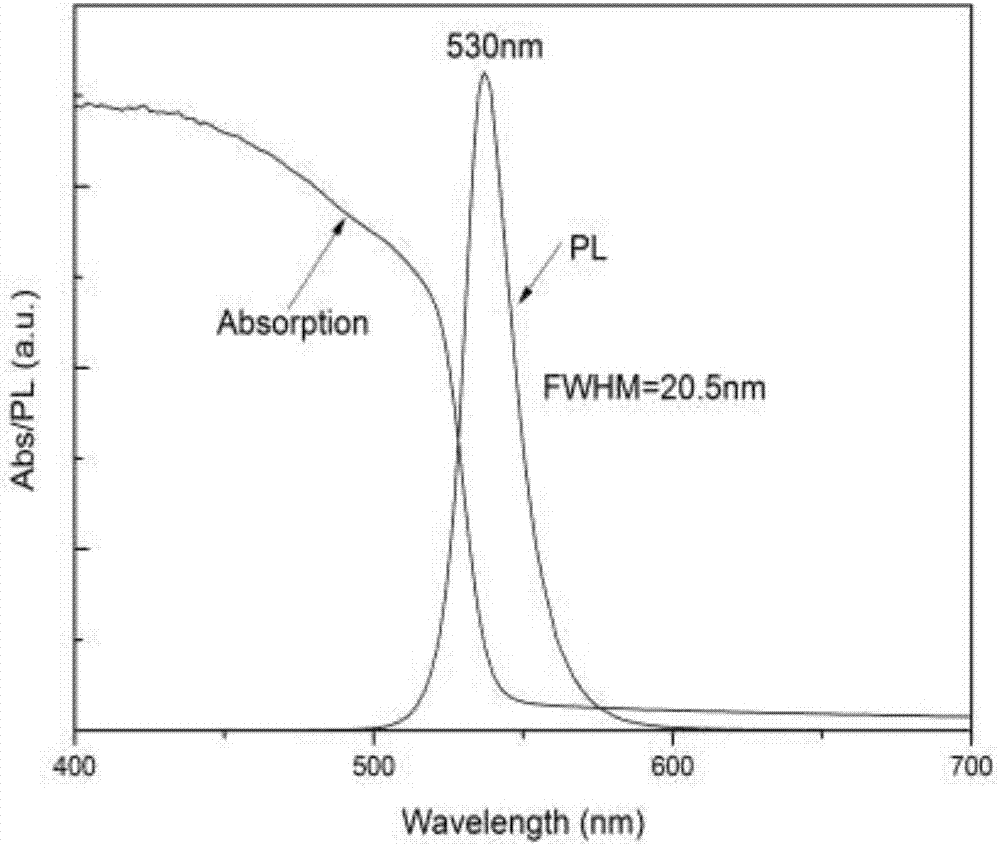

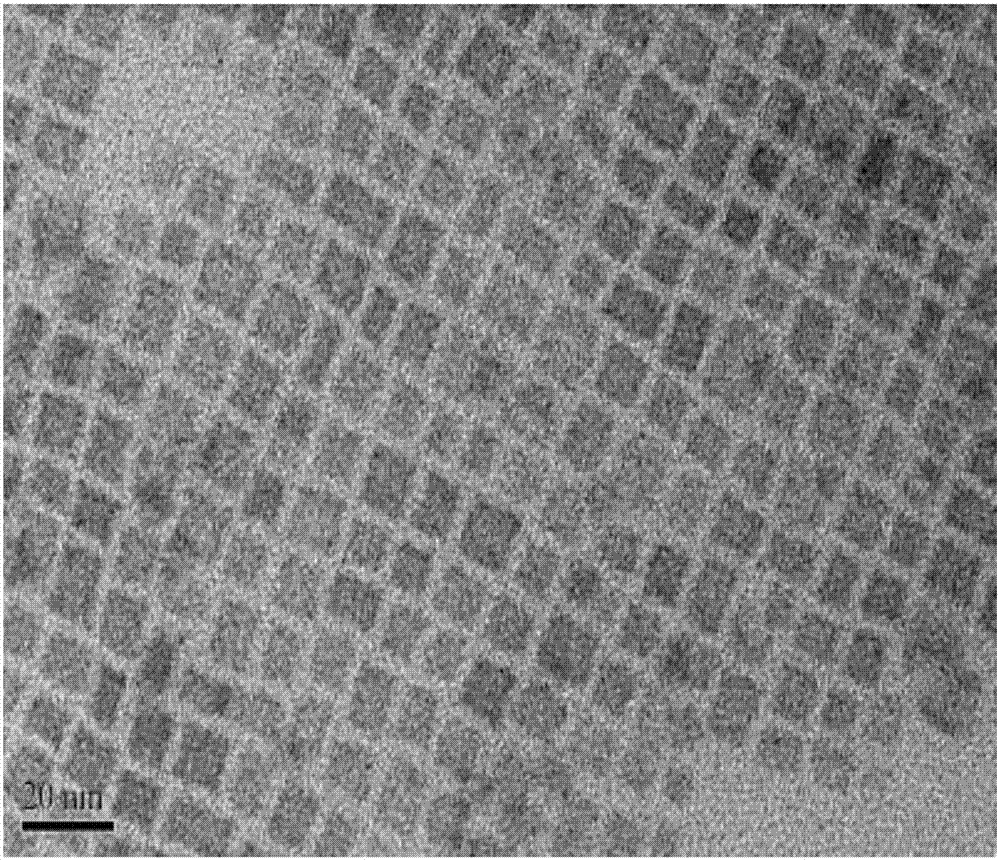

Low-temperature fast preparation method of perovskite luminous material of formamidine lead bromide nanometer crystals

A technology of luminescent materials and nanocrystals, which is applied in luminescent materials, chemical instruments and methods, nanotechnology, etc., can solve the problems of low preparation efficiency, difficulty in realizing and stably maintaining photoluminescence, and restrictions on mass production of FAPbBr, achieving synthesis The effect of short time and high synthesis efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] In this embodiment, a perovskite luminescent material formamidine lead bromide FAPbBr 3 The low-temperature rapid preparation method of nanocrystals comprises the following steps:

[0020] a. FAPbBr 3 Preparation of the original solution of nanocrystals: using 1-octadecene (ODE), oleic acid (OA), oleylamine bromide (OAmBr), PbO, and formamidine acetate (FA-oleate) as raw materials, according to the set formula Weigh the above raw materials and stir and mix evenly, that is, take a 25ml beaker, add 10ml of ODE, 1.5ml of OA, and then weigh 0.3mmol of 105mg of OAmBr, 0.2mmol of 44.6mg of PbO and 0.4mmol of 41.6mg of FA-oleate, then pour the weighed materials into a beaker, mix them together, and place the ultrasonic probe of VCX800 ultrasonic cell disruption in the solution in the above beaker, set the working time for 5 minutes, and mix evenly , to make the raw material mixture, that is to complete FAPbBr 3 Preparation of the original solution of nanocrystals;

[0021]...

Embodiment 2

[0028] This embodiment is basically the same as Embodiment 1, especially in that:

[0029] In this embodiment, a perovskite luminescent material formamidine lead bromide FAPbBr 3 The low-temperature rapid preparation method of nanocrystals comprises the following steps:

[0030] a. FAPbBr 3Preparation of the original solution of nanocrystals: using 1-octadecene (ODE), oleic acid (OA), oleylamine bromide (OAmBr), PbO, and formamidine acetate (FA-oleate) as raw materials, according to the set formula Weigh the above raw materials and stir and mix evenly, that is, take a 25ml beaker, add 9.5ml of ODE, 1.9ml of OA, and then weigh 0.3mmol of 105mg of OAmBr, 0.2mmol of 44.6mg of PbO and 0.4mmol of 41.6mg of FA-oleate, then pour the weighed materials into a beaker, mix them together, and place the ultrasonic probe of VCX800 ultrasonic cell disruption in the solution in the above beaker, set the working time for 10 minutes, and stir evenly Mix to make raw material mixture, that is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com