Hydrolysis-resistant aqueous polyester and preparation method thereof

A water-based polyester resin, hydrolysis-resistant technology, applied in the direction of polyester paint, coating, latex paint, etc., can solve the problems of hydrolysis resistance, water resistance, unsatisfactory coating film processing, poor storage stability, etc., to achieve Effect of reducing potential and strong hydrolysis resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

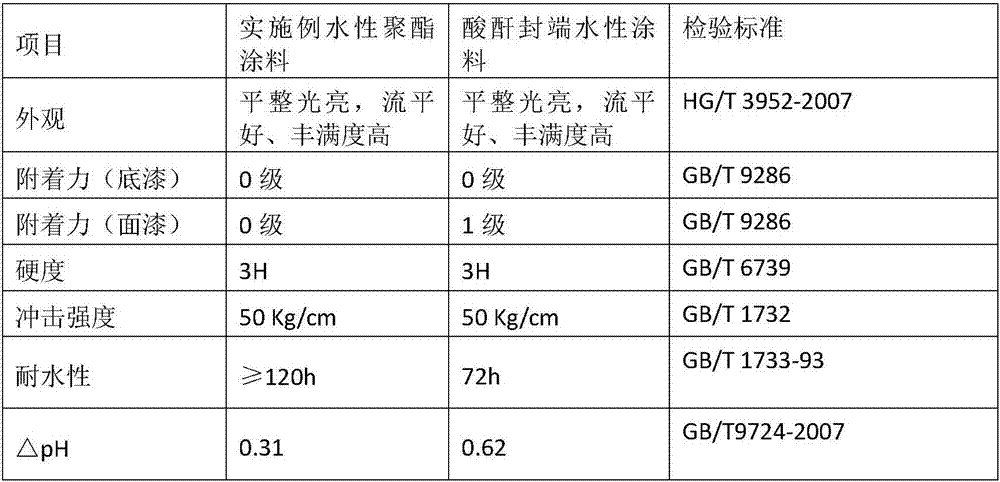

Examples

preparation example Construction

[0014] In another aspect, the present invention provides a method for preparing a hydrolysis-resistant water-based polyester, the steps are as follows;

[0015] 25-30g neopentyl glycol, 18-20g hexanediol, 18-22g 2-methyl-propylene glycol, 5-8g pentaerythritol, 10-12g adipic acid, 35-40g dimethylol propane acid, 12-15g Add terephthalic acid and 0.05-0.08g of dibutyltin oxide into a reaction vessel with a stirrer and a condenser, blow nitrogen, slowly raise the temperature to 140°C, and then raise the temperature to 240°C at a heating rate of 20°C / h, keep Esterification at this temperature until the acid value (KOH) reaches 30-60 mg / g, and the hydroxyl value (KOH) reaches 60-130 mg / g;

[0016] Then lower the temperature to 100°C, add 10-15g of ethylene glycol butyl ether and 25-30g of curing agent hexamethylolmelamine methyl ether resin, stir and dilute, and then neutralize with 3-5g of N,N-dimethylethanolamine to obtain the main chain Waterborne polyester with carboxyl functio...

Embodiment 1

[0019] The hydrolysis-resistant waterborne polyester resin provided by the present invention is made up of the following raw materials: 25g of neopentyl glycol, 18g of hexanediol, 18g of 2-methyl-propylene glycol, 5g of pentaerythritol, 10g of adipic acid, dimethylol Propanic acid 35g, terephthalic acid 12g, dibutyltin oxide 0.05g, ethylene glycol butyl ether 10g, hexamethylol melamine methyl ether resin 25g, N,N-dimethylethanolamine 3g.

[0020] The invention provides a method for preparing a hydrolysis-resistant water-based polyester, the steps are as follows;

[0021] 25g of neopentyl glycol, 18g of hexanediol, 18g of 2-methyl-propylene glycol, 5g of pentaerythritol, 10g of adipic acid, 35g of dimethylolpropanoic acid, 12g of terephthalic acid and 0.05g of dibutyltin oxide were added to the tape In the reaction vessel of the stirrer and the condenser, pass nitrogen, slowly heat up to 140°C, then heat up to 240°C at a heating rate of 20°C / h, keep this temperature for esterif...

Embodiment 2

[0024] The invention provides a hydrolysis-resistant water-based polyester resin, which is composed of the following raw materials: 30 g of neopentyl glycol, 20 g of hexanediol, 22 g of 2-methyl-propylene glycol, 8 g of pentaerythritol, 12 g of adipic acid, and dimethylol Propanic acid 40g, terephthalic acid 15g, dibutyltin oxide 0.08g, ethylene glycol butyl ether 15g, hexamethylol melamine methyl ether resin 30g, N,N-dimethylethanolamine 5g.

[0025] The invention provides a method for preparing a hydrolysis-resistant water-based polyester, the steps are as follows;

[0026] 30g of neopentyl glycol, 20g of hexanediol, 22g of 2-methyl-propylene glycol, 8g of pentaerythritol, 12g of adipic acid, 40g of dimethylolpropanoic acid, 15g of terephthalic acid and 0.08g of dibutyltin oxide were added to the tape In the reaction vessel of the stirrer and the condenser, pass nitrogen, slowly heat up to 140°C, then heat up to 240°C at a heating rate of 20°C / h, keep this temperature for es...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com