Polyvinyl chloride elastomer cable material for charging pile cables and preparation method thereof

A polyvinyl chloride, polyvinyl chloride resin technology, applied in the direction of circuits, insulators, electrical components, etc., can solve the problems of insufficient heat resistance and elasticity, insufficient cold resistance, no matte high-end appearance, etc., and achieve good processing performance , high oil resistance, good resilience effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

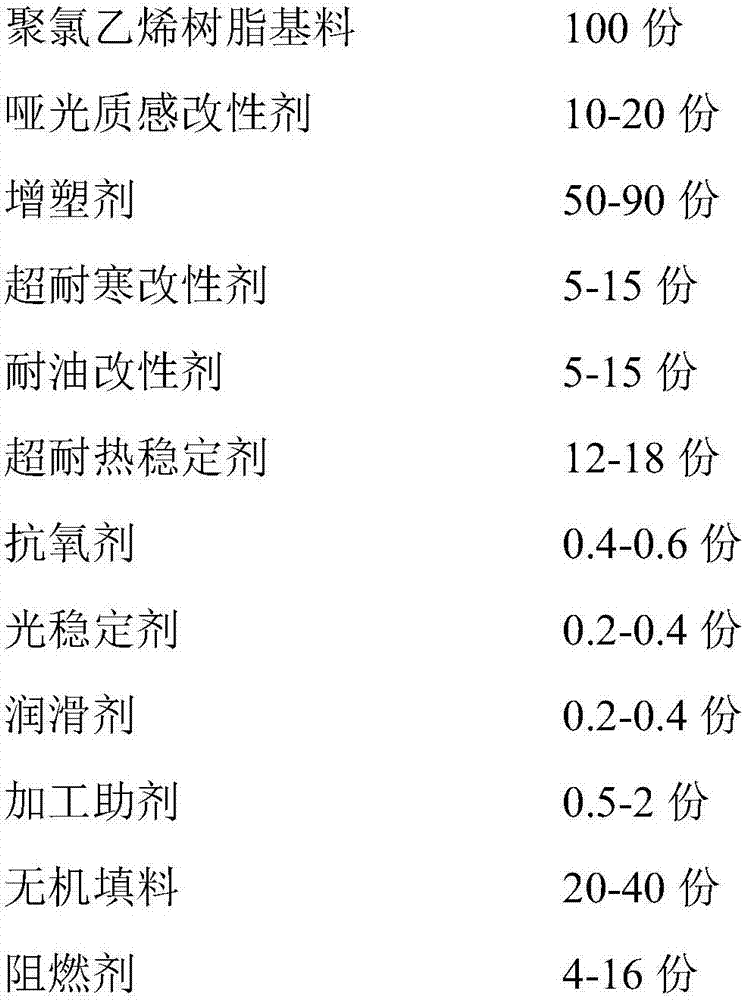

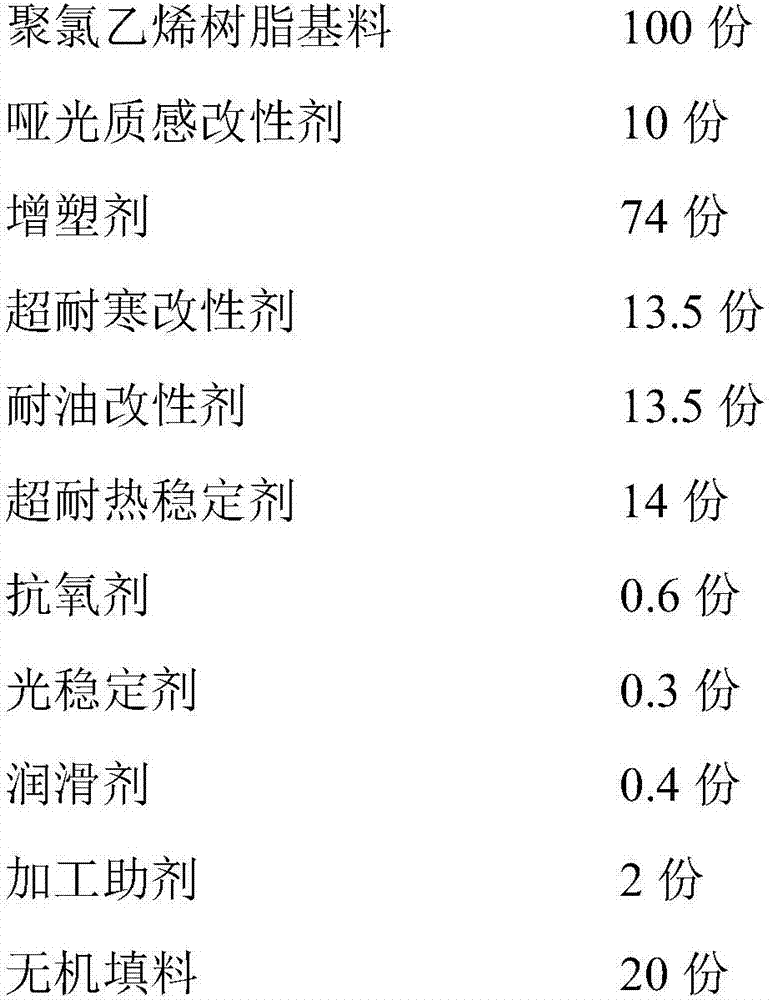

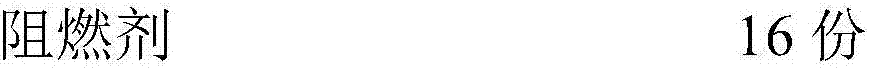

[0037] A polyvinyl chloride elastomer cable material for charging pile cables in this embodiment includes the following components in parts by weight:

[0038]

[0039]

[0040] The polyvinyl chloride resin base material is composed of ultra-high molecular weight polyvinyl chloride resin (HPVC) and gel polyvinyl chloride resin (gel PVC) with an average degree of polymerization greater than or equal to 2200. The ultra-high molecular weight polyvinyl chloride resin is 50 parts. Glue polyvinyl chloride resin is 50 parts.

[0041] The matte texture modifier is EVA-MAH.

[0042] The plasticizer is TM810.

[0043] The super cold resistance modifier is ethylene / butyl acrylate / carbonyl copolymer.

[0044] The oil resistance modifier is carbonyl-modified ethylene vinyl acetate, which has excellent oil resistance, adding a small amount can obviously improve the oil resistance of the material.

[0045] The super heat-resistant stabilizer is a high-efficiency calcium / zinc super h...

Embodiment 2-6

[0058] The raw materials and preparation method of the polyvinyl chloride elastomer cable material for charging pile cables in Examples 2-6 are basically the same as those in Example 1, except for the specific components and proportions, which are listed in Table 1:

[0059] Composition and consumption table of table 1 embodiment 1-6

[0060]

[0061]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com