Cascade microsphere resonant cavity type humidity sensor

A microsphere resonant cavity, humidity sensor technology, applied in transmittance measurement and other directions, can solve the problems of reducing sensor stability and service life, affecting sensing performance, polymer aging, etc., achieving small size, high sensitivity, and stability. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

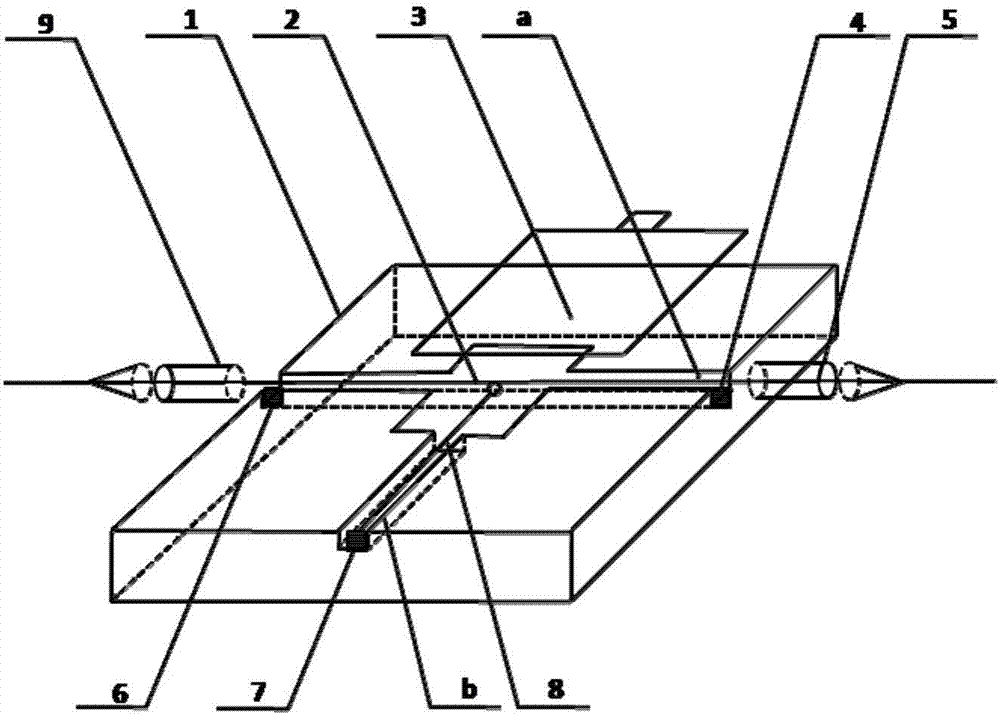

[0026] exist figure 1 Among them, the cascaded microsphere resonant cavity type humidity sensor of the present invention includes a sensor substrate 1. The sensor substrate 1 of this embodiment is made of acrylic glass, and the sensor substrate 1 is provided with horizontal installation grooves a and vertical installation grooves perpendicular to each other. b, in the horizontal installation slot a, the taper fiber 2 is fixedly installed with the taper fiber left adjustment screw 4 and the taper fiber right adjustment screw 7. The taper fiber 2 in this embodiment is pulled by a commercial 1550 optical fiber with a diameter of 125um. Made by cone method, the diameter of the cone area is 1um, the evanescent field in the fusion cone fiber 2 is more likely to be coupled, and the sensor sensitivity is improved. The left adjustment screw 4 of the fusion cone fiber and the right adjustment screw 7 of the fusion cone fiber can be adjusted and controlled. The height of the conical fibe...

Embodiment 2

[0028] In the above-mentioned embodiment 1, the fusion-tapered optical fiber 2 of the present embodiment is made by a commercial 1550 optical fiber with a diameter of 125um using the method of flame tapering, and the diameter of the cone area is 0.5um. The connection relationship and implementation of the remaining parts and parts Example 1 is exactly the same.

Embodiment 3

[0030] In the above-mentioned embodiment 1, the fusion-tapered optical fiber 2 of the present embodiment is made of a commercial 1550 optical fiber with a diameter of 125um by means of flame tapering, and the diameter of the cone area is 3um. 1 is exactly the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com