Sodium-ion battery electrolyte additive containing rubidium and/or caesium cations, and applications thereof

An electrolyte additive, sodium ion battery technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problem that sodium ions cannot be inserted and removed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

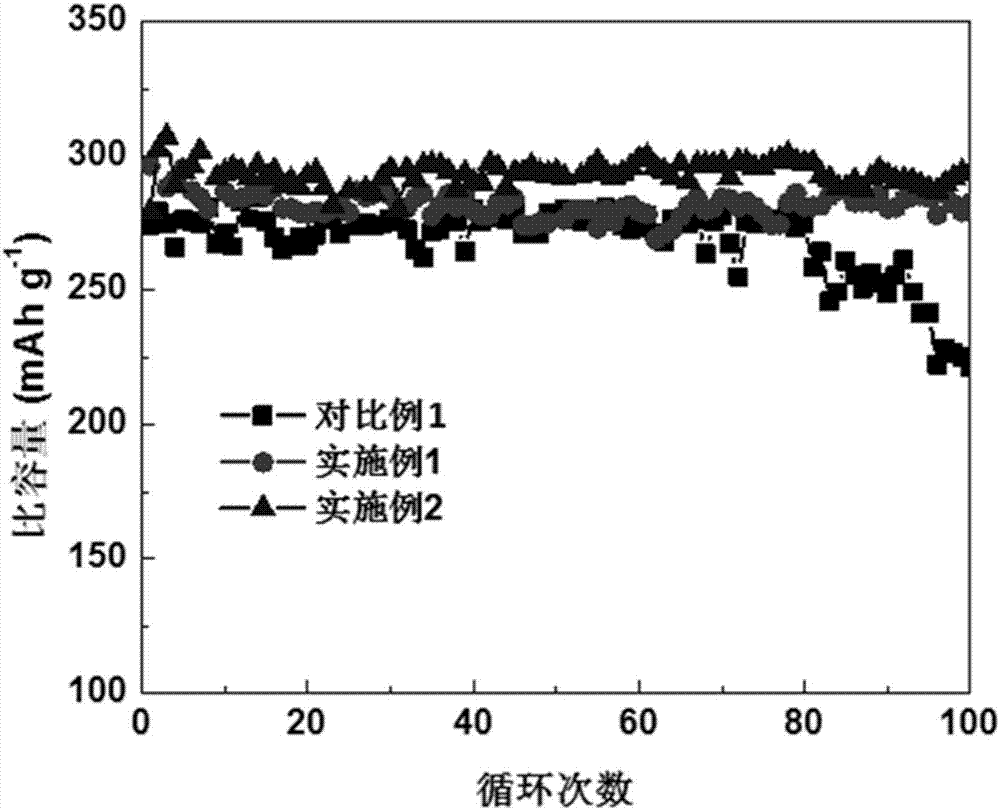

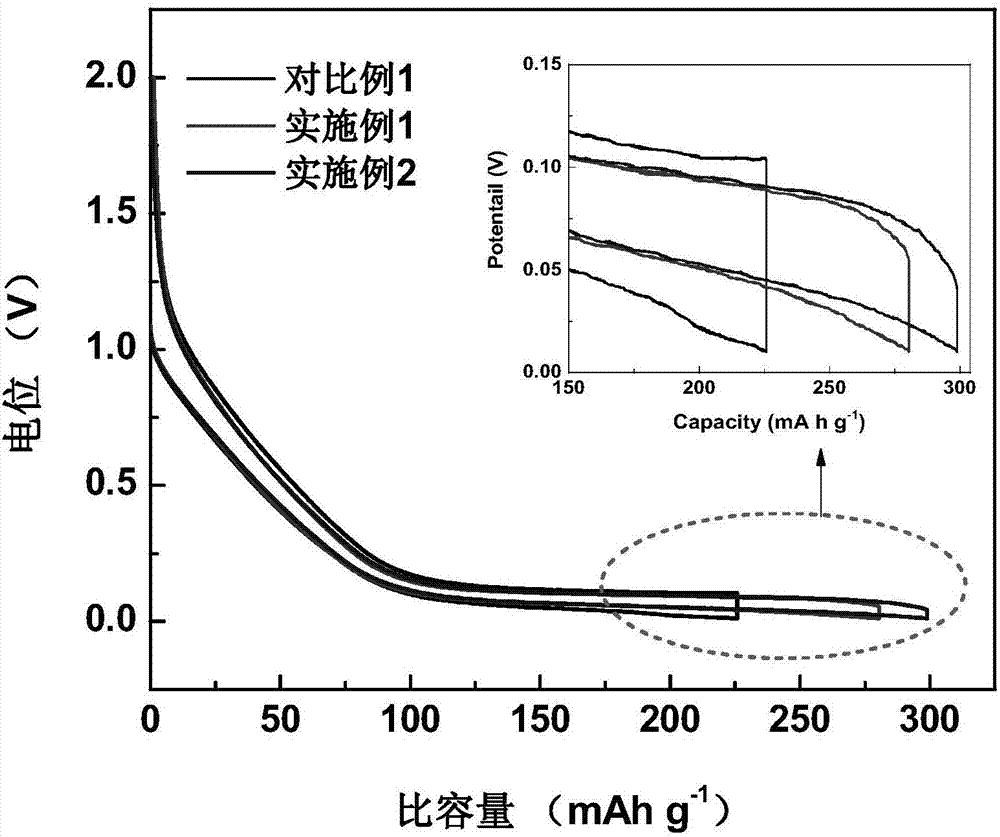

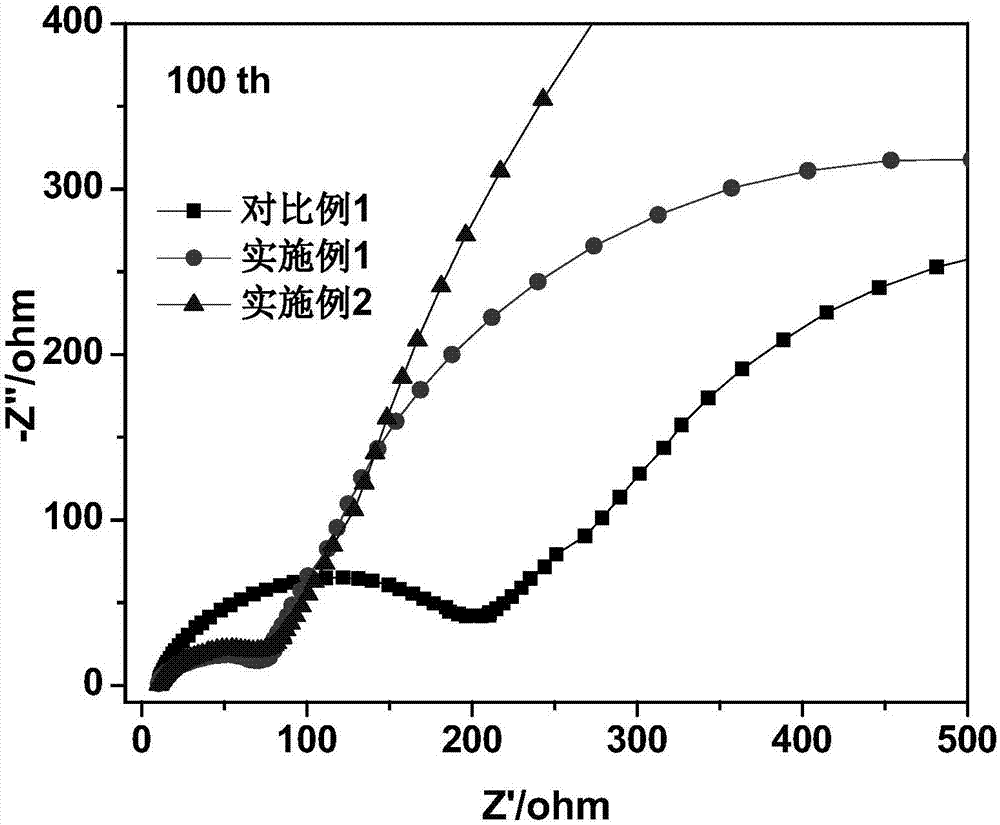

Embodiment 1

[0056] Mix PC and EC well, add RbPF 6 Stir to dissolve, then add NaPF 6 , and finally add FEC, stir and dissolve to obtain the required electrolyte. Wherein the volume ratio of PC and EC is 4:1, RbPF 6 The concentration is 0.05mol / L, NaPF 6 The concentration of FEC is 0.8mol / L, and the mass percentage of FEC is 2% (the additive mass accounts for the percentage of the total mass of the electrolyte).

[0057] A sodium-ion battery was assembled with the above electrolyte, with metal sodium as the counter electrode, active material hard carbon as the working electrode, glass fiber separator, and CR2016 button battery.

Embodiment 2

[0059] Mix PC and EC evenly, add CsPF 6 Stir to dissolve, then add NaPF 6 , and finally add FEC, stir and dissolve to obtain the required electrolyte. Wherein the volume ratio of PC and EC is 4:1, CsPF 6 The concentration is 0.05mol / L, NaPF 6 The concentration of FEC is 0.8mol / L, and the mass percentage of FEC is 2% (the additive mass accounts for the percentage of the total mass of the electrolyte).

[0060] A sodium-ion battery was assembled with the above electrolyte, with metal sodium as the counter electrode, active material hard carbon as the working electrode, glass fiber separator, and CR2016 button battery.

Embodiment 3

[0062] Mix PC, EC and DEC evenly, add RbPF 6 Stir to dissolve, then add NaPF 6 , and finally add FEC, stir and dissolve to obtain the required electrolyte. The volume ratio of PC, EC and DEC is 4:1:5, RbPF 6 The concentration is 0.05mol / L, NaPF 6 The concentration of FEC is 0.8mol / L, and the mass percentage of FEC is 2% (the additive mass accounts for the percentage of the total mass of the electrolyte).

[0063] A sodium-ion battery was assembled with the above electrolyte, with metal sodium as the counter electrode, active material hard carbon as the working electrode, glass fiber separator, and CR2016 button battery.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molar concentration | aaaaa | aaaaa |

| Molar concentration | aaaaa | aaaaa |

| Molar concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com