A kind of preparation method of cold brewed tea

A technology of cold-brewing tea and fresh tea leaves, which is applied in the field of cold-brewing tea preparation. It can solve problems such as low leaching of contained components, deepening of tea soup color, and failure to meet the requirements of rapid cold brewing, so as to achieve large market development potential, The taste of tea soup is fresh and mellow, and the effect of maintaining stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A preparation method for cold-brewed green tea, comprising the following steps:

[0030] (1) The picked fresh tea leaves are screened to remove broken leaves, moth-eaten leaves, etc., and then the screened fresh tea leaves are spread out so that they lose luster, slightly lose water, shrink slightly and emit floral fragrance. After the spreading is completed, microwave fixation is carried out. The conditions for microwave fixation are: under the condition of 100g of fresh tea leaves, the microwave power is 700w, and the fixation time is 90s;

[0031] (2) Cool the fresh tea leaves after microwave cleaning to 25°C, knead, cut and granulate, and screen out the granules with specifications of 10 mesh;

[0032] (3) Spread the granular material into a thin layer, spread it evenly on the material tray, and put it in a refrigerator at -80°C for 4 hours to ensure that the moisture in the raw material is completely frozen to obtain the pre-frozen material;

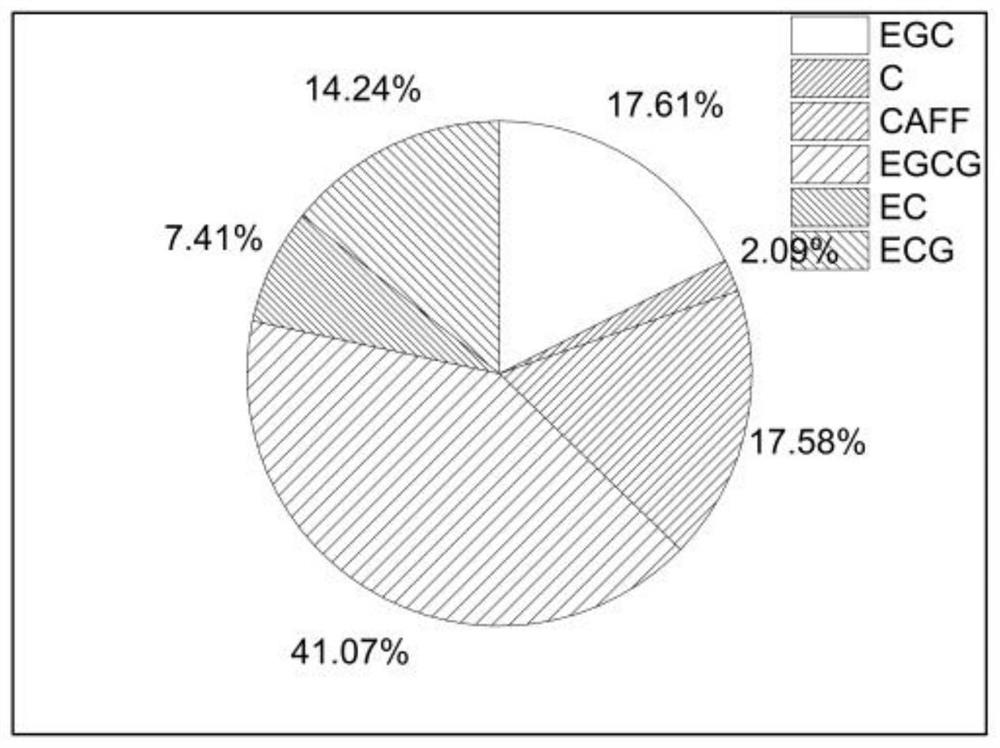

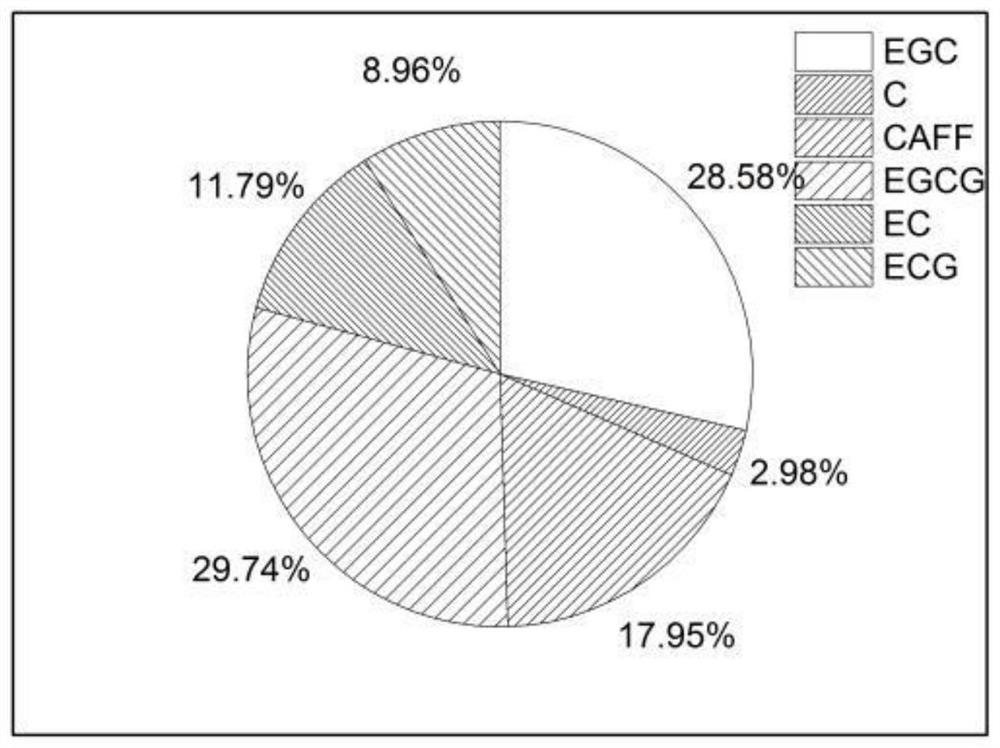

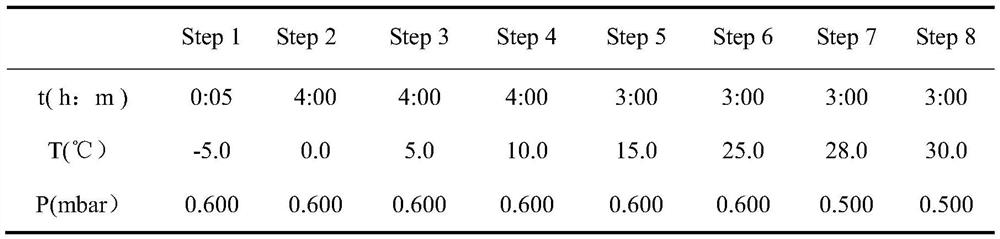

[0033] (4) Vacuum fr...

Embodiment 2

[0050] A method for preparing cold-brewed green tea, the specific steps are similar to those in Example 1, the difference is that the granular material screened in this example has a specification of 6 mesh; in this example, the granular material is put into a refrigerator at -20°C for 12 hours ; In this embodiment, the pre-frozen material is subjected to vacuum freeze-drying under the conditions of a pressure of 0.5 mbar and a temperature of 10° C.; in this embodiment, the microwave is used to increase the aroma for 40 s.

Embodiment 3

[0052] A method for preparing cold-brewed green tea, the specific steps are similar to those in Example 1, the difference is that the granular material screened in this example has a specification of 40 mesh; in this example, the granular material is put into a -50°C refrigerator and frozen for 8 hours ; In this embodiment, the pre-frozen material is vacuum freeze-dried under the conditions of a pressure of 0.6 mbar and a temperature of 30 ° C; in this embodiment, the microwave is used to increase the aroma for 60 s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com