Production process for preparing blueberry enzyme by biological enzyme method

A production process, blueberry enzyme technology, applied to bacteria used in food preparation, food science, and the function of food ingredients, etc., can solve the problems of reduced activity of superoxide dismutase, lack of enzyme efficacy, anthocyanin loss, etc. Achieve good enzymatic hydrolysis effect, improve antioxidant performance, and promote leaching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

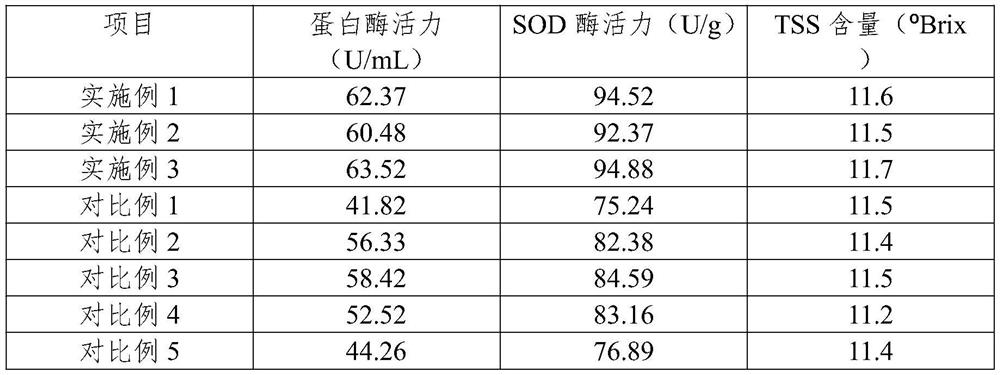

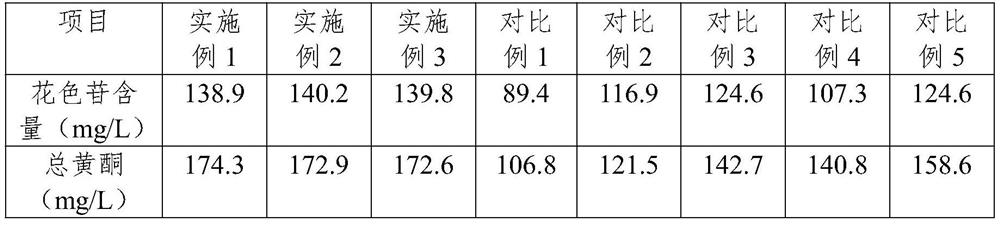

Examples

Embodiment 1

[0019] The production process of blueberry enzyme includes the following steps:

[0020] (1) blueberry pretreatment is: selecting complete and healthy blueberries, cleaning and beating, and in the blueberry beating process, the pulp fragmentation degree is greater than 60%, and blueberry pulp is obtained for subsequent use;

[0021] (2) Carbon dioxide immersion: Put the above blueberry pulp in a closed container and vacuumize it, then keep the pressure for 1 hour, then fill the container with a sufficient amount of carbon dioxide, fully immerse it in a temperature environment of 20 ° C for 10 hours, and then take it out. Impregnating slurry for use;

[0022] (3) Ultrasonic catalyzed enzymatic hydrolysis is to take out the above-mentioned impregnated slurry and place it in a wall breaker for ultra-fine crushing, then add 0.1% of the total amount of pectinase in the impregnated slurry, mix and stir evenly, and then place it in an ultrasonic device. Ultrasonic power of 420W, ult...

Embodiment 2

[0026] The production process of blueberry enzyme includes the following steps:

[0027] (1) blueberry pretreatment is: selecting complete and healthy blueberries, cleaning and beating, and in the blueberry beating process, the pulp fragmentation degree is greater than 60%, and blueberry pulp is obtained for subsequent use;

[0028] (2) Carbon dioxide immersion: Place the above blueberry pulp in a closed container and vacuumize it, hold the pressure for 2 hours, then fill the container with a sufficient amount of carbon dioxide, fully immerse it in a temperature environment of 25 ° C for 15 hours, and then take it out. Impregnating slurry for use;

[0029] (3) Ultrasonic catalyzed enzymatic hydrolysis is to take out the above impregnated slurry and place it in a wall breaker for ultra-fine crushing, then add 1.5% of the total amount of pectinase in the impregnated slurry, mix and stir evenly, and then place it in an ultrasonic device. Ultrasonic power of 420W, ultrasonic freq...

Embodiment 3

[0033] The production process of blueberry enzyme includes the following steps:

[0034] (1) blueberry pretreatment is: selecting complete and healthy blueberries, cleaning and beating, and in the blueberry beating process, the pulp fragmentation degree is greater than 60%, and blueberry pulp is obtained for subsequent use;

[0035] (2) Carbon dioxide immersion: Put the above blueberry pulp in a closed container and vacuumize it, then keep the pressure for 2 hours, then fill the container with a sufficient amount of carbon dioxide, fully immerse it in a temperature environment of 20 ° C for 13 hours, and then take it out. Impregnating slurry for use;

[0036] (3) Ultrasonic catalyzed enzymatic hydrolysis is to take out the above-mentioned impregnated slurry and place it in a wall breaker for ultra-fine crushing, then add 1% of the total amount of pectinase to the impregnated slurry, mix and stir evenly, and then place it in an ultrasonic device. Ultrasonic power of 420W, ultr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com