Preparation method of modified activated carbon for removing formaldehyde in air in high efficiency

An activated carbon and air technology, applied in chemical instruments and methods, gas treatment, membrane technology, etc., can solve the problems of low adsorption capacity of formaldehyde, short replacement cycle, easy secondary pollution, etc., and achieve low price, safe raw materials, and simple methods. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

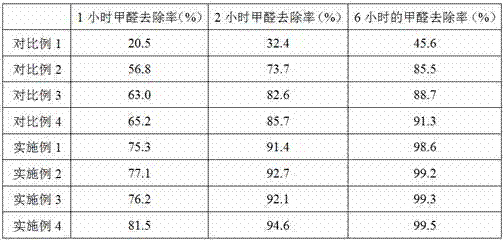

Examples

Embodiment 1

[0018] (1) Raw material preparation: Measure the saturated adsorption water M of coal-based activated carbon according to the following operations:

[0019] Weigh 1Kg coal-based activated carbon, add water and measure M 0 , stir evenly to achieve full adsorption, and then weigh the filtrate mass M after suction filtration 1 , subtract this mass to get the amount of water M adsorbed n , namely M n = M 0 - M 1 , repeat the measurement several times, take M n The average value of the coal-based activated carbon is the saturated adsorption water M=600g / Kg;

[0020] Use 1Kg of 5-10 mesh granular coal-based activated carbon as the base carbon, and weigh 12% of the base carbon’s mass of nitrogen-containing substances (including 80g of ammonium chloride NH 4 Cl and 40g urea CO(NH 2 ) 2 ); Take 1200g of deionized water twice the amount of saturated adsorbed water M;

[0021] (2) Loading process: Dissolve the nitrogen-containing substance in step (1) in deionized water, then ad...

Embodiment 2

[0025] (1) Raw material preparation: Measure the saturated adsorption water M of coconut shell activated carbon according to the following operations:

[0026] Weigh 1Kg of coconut shell activated carbon to be tested, add water and measure M 0 , stir evenly to achieve full adsorption, and then weigh the filtrate mass M after suction filtration 1 , subtract this mass to get the amount of water M adsorbed n , namely M n = M 0 - M 1 , repeat the measurement several times, take M n The average value promptly obtains the saturated adsorption water amount M=900g / Kg of this tested coconut shell activated carbon;

[0027] With 1kg of amorphous coconut shell activated carbon of 10-28 mesh as the base carbon, weigh 9% nitrogen-containing substances (containing 60g of ammonium bicarbonate NH 4 HCO 3 And 30g diethylamine; Get 900g of deionized water 1 times of the saturated adsorption water amount M;

[0028] (2) Loading process: Dissolve the nitrogen-containing substance in step ...

Embodiment 3

[0032] (1) Raw material preparation: measure the saturated adsorption water M of wood activated carbon according to the following operations:

[0033] Weigh 1Kg wood activated carbon to be tested, add water and measure M 0 , stir evenly to achieve full adsorption, and then weigh the filtrate mass M after suction filtration 1 , subtract this mass to get the amount of water M adsorbedn , namely M n = M 0 - M 1 , repeat the measurement several times, take M n The average value promptly obtains the saturated adsorption water amount M=500g / K of this wooden activated carbon to be tested;

[0034] Take 1 kg of 40-80 mesh powdered woody activated carbon as the base carbon, and weigh 1% of the base carbon’s mass of nitrogen-containing substances (including 5g of ammonium sulfate (NH 4 ) 2 SO 4 and 5g triethylamine); take 500g of deionized water that is 1 times the saturated adsorption water amount M;

[0035] (2) Loading process: Dissolve the nitrogen-containing substance in st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com