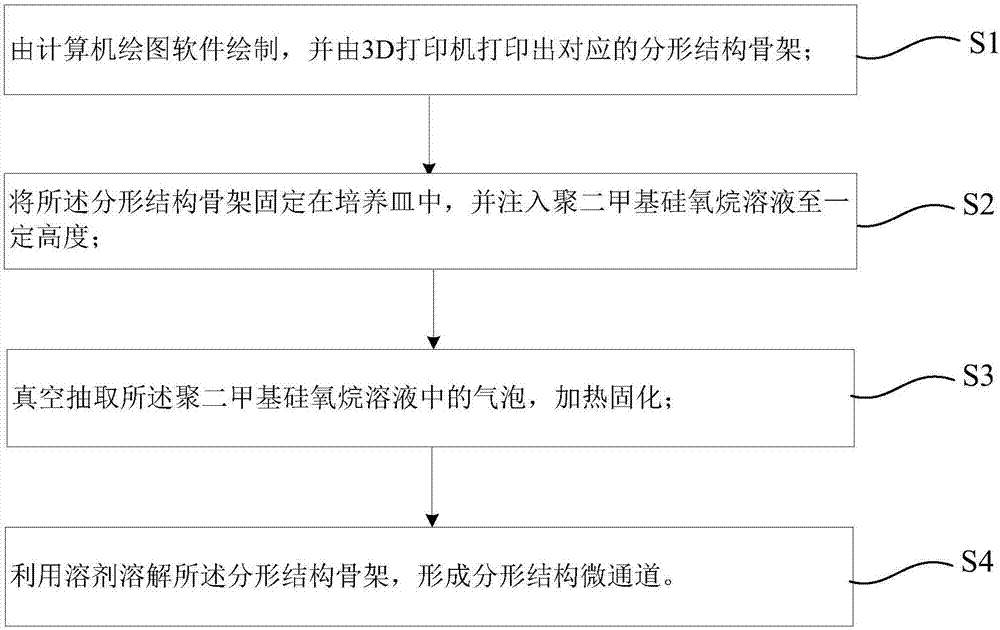

Method for preparing fractal-structured microchannel through 3D printing

A fractal structure and 3D printing technology, applied in the field of micromachining, can solve the problems of complex process, difficult preparation of complex fractal structure microchannels, high cost, etc., and achieve the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

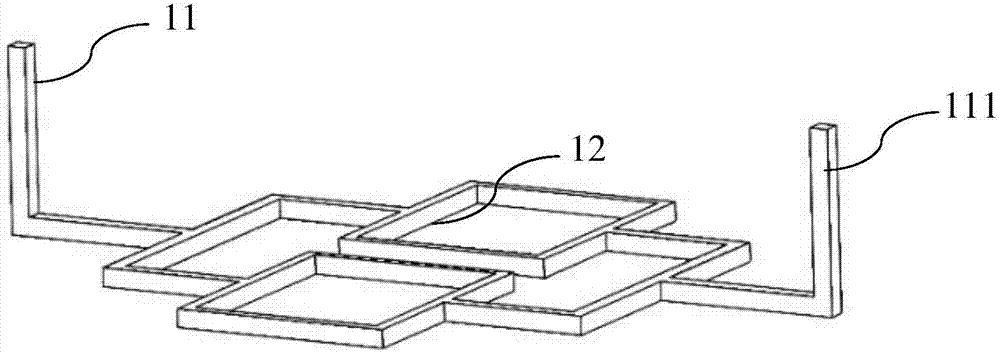

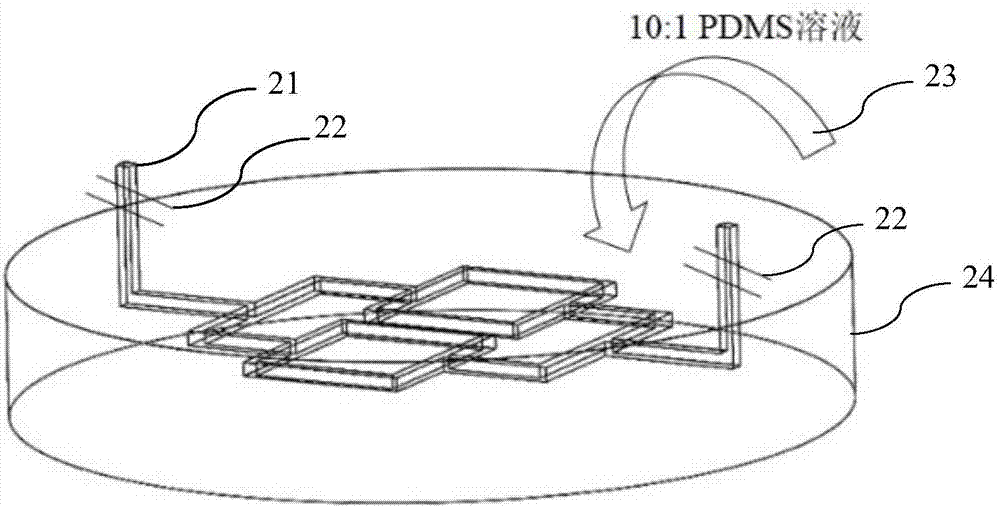

[0047] see Figure 2 to Figure 4 , this embodiment provides a method for preparing a single-layer fractal structure microchannel by 3D printing. The process of preparing a fractal-structure microchannel by 3D printing is as follows: firstly, a computer is used to draw a single-layer wedge-shaped fractal structure skeleton. like figure 2 As shown, the thickness of the skeleton of the fractal structure involved is 1mm. The fractal structure is composed of 2 levels of bifurcations and 5 skeletons of different lengths. 1mm. At both ends of the skeleton, a branch with a length of 20 mm is connected to the first terminal far away from the center of the skeleton with a first vertical support 11 perpendicular to the plane where the main body 12 of the fractal structure is located, and its length is 50 mm, and one end is connected to the on the skeleton of the fractal structure described above. On the second terminal corresponding to the first terminal, a second vertical support 11...

Embodiment 2

[0056] see Figure 5 and Image 6 , this embodiment provides a method for preparing a multilayer fractal structure microchannel, the preparation method of the multilayer structure microchannel includes: 3D printing a double-layer fractal structure skeleton, and the double-layer fractal structure skeleton is obtained by computer drawing. like Figure 5 As shown, preferably, it is composed of 7 levels of branches in an "H-shaped" structure, and its lengths are: 50mm, 38.7mm, 31.7mm, 25.2mm, 20mm, 15.9mm, 12.6mm, and the widths are 3mm, 2.38mm, 1.89mm, 1.50mm, 1.19mm, 0.94mm, 0.75mm, the thickness is 1mm.

[0057] The described double-layer fractal structure skeleton comprises a first "H-shaped" fractal skeleton plane 42 and a second "H-shaped" fractal skeleton plane 43, and the two fractal planes are connected by a vertical connection skeleton 44, and the vertical connection skeleton 44 The length is 2mm. The first "H-type" fractal skeleton plane 42 is included, and its leng...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com