Polyamide material used for selective laser sintering and preparation method of same

A laser sintering and polyamide technology, applied in the field of additive manufacturing, can solve the problems of high thermal stability of powder, poor toughness of nylon workpiece, and high working temperature, and achieve the effect of improving fluidity, easy implementation and reducing voids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

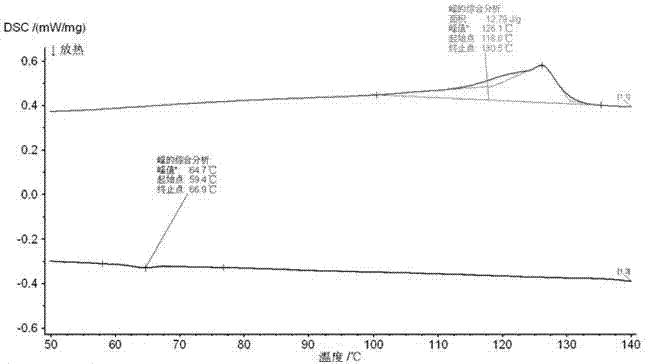

Image

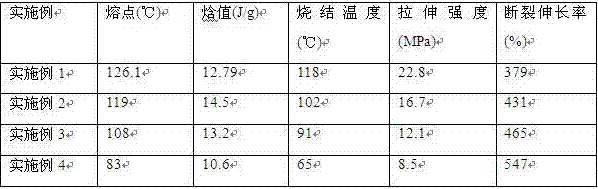

Examples

preparation example Construction

[0030] The present invention also provides a method for preparing a polyamide material for selective laser sintering, comprising the following steps:

[0031] Step 1. Copolymerize the short carbon chain nylon salt, the first long carbon chain nylon salt, and the second long carbon chain nylon salt of different types to obtain polyamide pellets;

[0032]In this step one, the weight ratio of the short carbon chain nylon salt, the first long carbon chain nylon salt and the second long carbon chain nylon salt can be preferably 1:1:0.2-0.8, which can better ensure that the polyamide The low melting point of the powder, and the high toughness of the sintered parts through the polyamide powder. Further preferably, in order to ensure the beneficial effects of low melting point and high toughness, the short carbon chain nylon salt, the first long carbon chain nylon salt and the second long carbon chain nylon salt are prepared into polyamide pellets by ternary copolymerization.

[0033...

Embodiment 1

[0041] Calculated by weight ratio, prepare materials in the following weight ratios:

[0042] Caprolactam: Nylon 11 salt: Nylon 1010 salt=0.2:1:1

[0043] Put the prepared caprolactam, nylon 11 salt, and nylon 1010 salt into the polymerization kettle, mix well, and then add the following additives for copolymerization:

[0044] Adipic acid, added in an amount of 0.2% of the total weight (the total weight here is the total weight of caprolactam, nylon 11 salt and nylon 1010 salt).

[0045] Hindered phenolic antioxidant, added in an amount of 0.2% of the total weight (the total weight here is the total weight of caprolactam, nylon 11 salt and nylon 1010 salt).

[0046] After evacuating the polymerization kettle containing the reactant, fill it with nitrogen dioxide gas to 0.3-0.4Mpa, then discharge the gas and heat it. When the temperature in the kettle rose to 220°C, the pressure in the kettle reached 1.5Mpa, and the pressure holding time was 1.5 hours. After the temperature...

Embodiment 2

[0050] Calculated by weight ratio, prepare materials in the following weight ratios:

[0051] Caprolactam: Nylon 11 salt: Nylon 1212 salt=0.4:1:1

[0052] Put caprolactam, nylon 11 salt, and nylon 1212 salt into the polymerization kettle, mix well, and then add the following additives for copolymerization:

[0053] Adipic acid, added in an amount of 0.4% of the total weight (the total weight here is the total weight of caprolactam, nylon 11 salt and nylon 1212 salt).

[0054] Hindered phenolic antioxidant, added in an amount of 0.4% of the total weight (the total weight here is the total weight of caprolactam, nylon 11 salt and nylon 1212 salt).

[0055] After evacuating the polymerization kettle containing the reactant, fill it with nitrogen dioxide gas to 0.3-0.4Mpa, then discharge the gas and heat it. When the temperature in the kettle rose to 225°C, the pressure in the kettle reached 1.6Mpa, and the pressure holding time was 2 hours. After the temperature in the kettle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com