Halogen-free and flame-retardant composite polyimide foam material and preparation method thereof

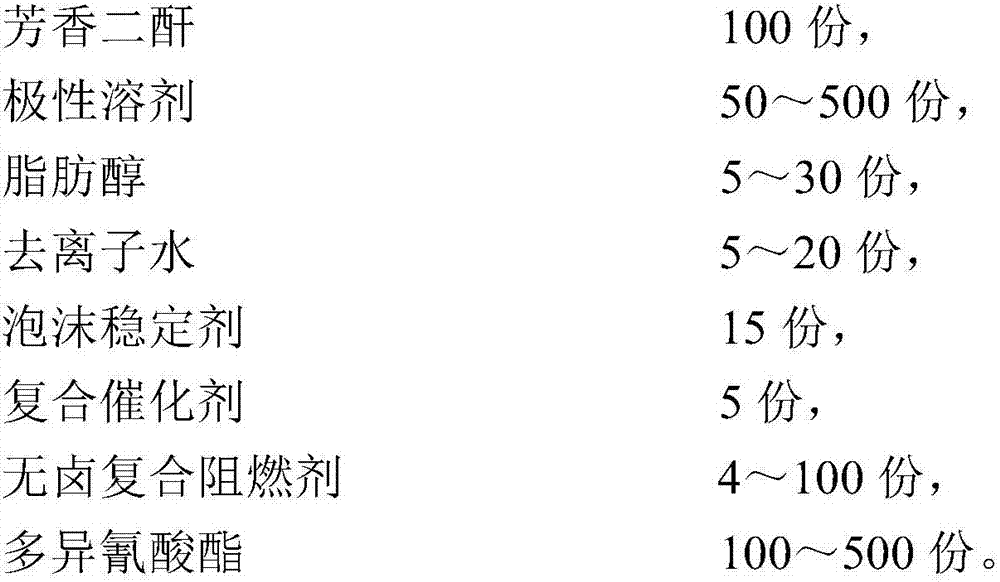

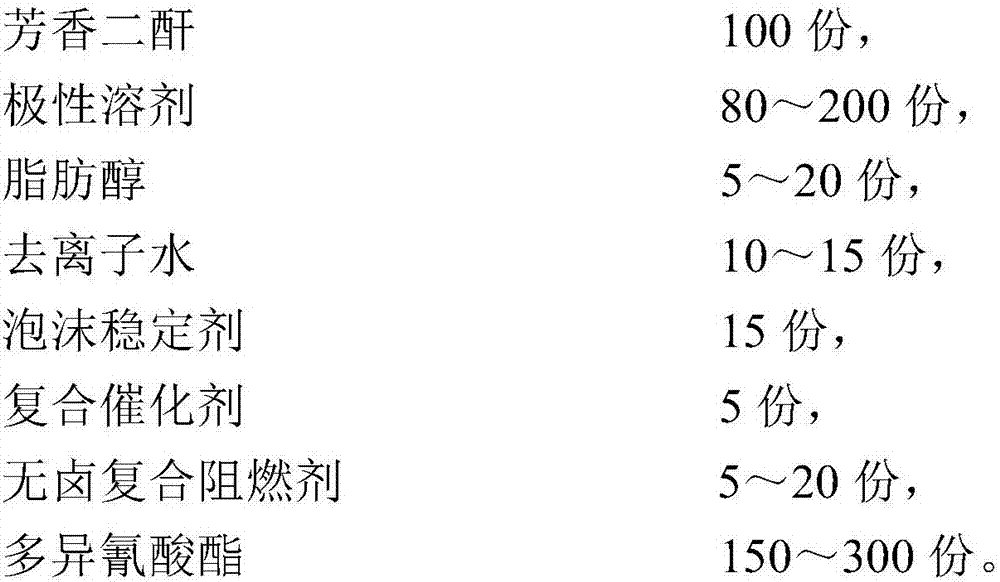

A foam material and polyimide technology, applied in the field of low-density halogen-free composite flame-retardant polyimide foam material and its preparation, can solve the problems of low density, insufficient structure and use performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

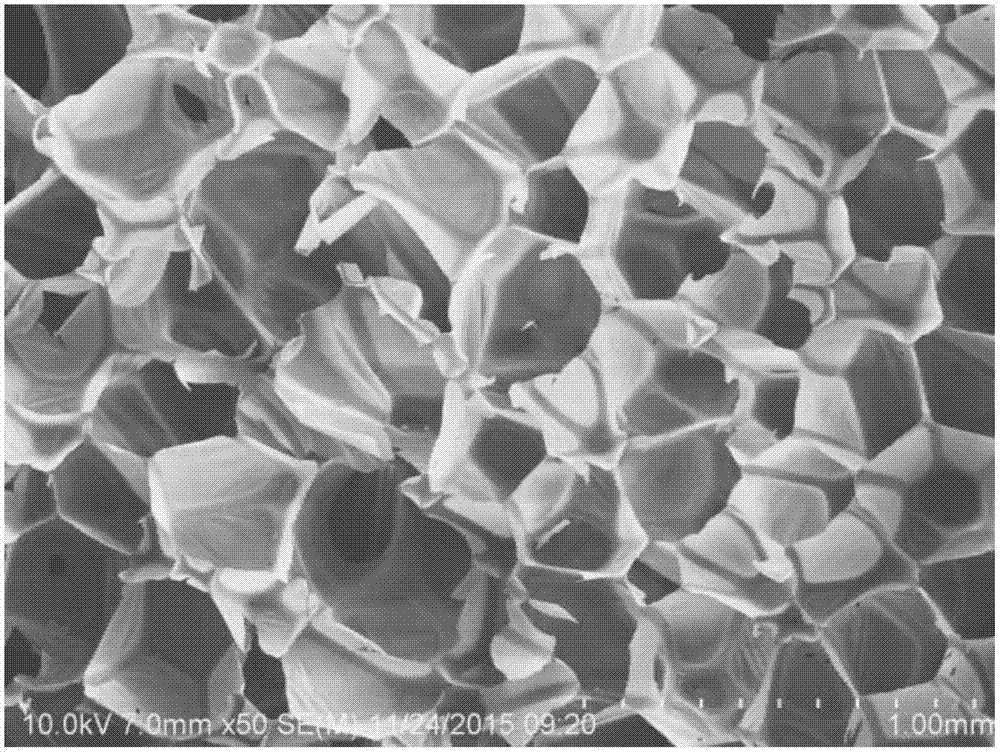

Image

Examples

Embodiment 1

[0056] (1) Graphite and red phosphorus prepare a halogen-free composite flame retardant with a weight ratio of 1:0.5; the specific preparation process is as follows:

[0057] Put 6.67g of expanded graphite, 3.33g of elemental red phosphorus and 200g of steel balls with a diameter of 6mm into a 100mL steel sealed tank, vacuumize the sealed tank, and carry out ball milling at a ball milling speed of 480rpm for 48 hours. The obtained black powder is It is a halogen-free composite flame retardant;

[0058] (2) Heat 100 parts of BTDA and 100 parts of DMF to 100°C and disperse evenly, add 15 parts of methanol to reflux at 70°C for esterification for 0.5h to obtain a clear solution A;

[0059] (3) Disperse 10 parts of deionized water, 15 parts of foam stabilizer and 5 parts of composite catalyst in the clarified solution A in step (2) at 60°C, and then add 5 parts of halogen-free composite flame retardant to obtain a uniform Suspension B;

[0060] (4) 200 parts of PAPI are quickly ...

Embodiment 2

[0064] (1) Graphite and red phosphorus prepare a halogen-free composite flame retardant with a weight ratio of 1:1; the specific preparation process is as follows:

[0065] Put 5g of expanded graphite, 5g of elemental red phosphorus and 200g of steel balls with a diameter of 6mm into a 100mL steel airtight tank, vacuumize the inside of the airtight tank, and perform ball milling at a ball milling speed of 480rpm for 48 hours to obtain a black powder that is Halogen compound flame retardant;

[0066] (2) Heat 100 parts of BTDA and 100 parts of DMF to 100°C and disperse evenly, add 15 parts of methanol to reflux at 70°C for esterification for 0.5h to obtain a clear solution A;

[0067] (3) Disperse 10 parts of deionized water, 15 parts of foam stabilizer and 5 parts of composite catalyst in the clarified solution A in step (2) at 60°C, and then add 5 parts of halogen-free composite flame retardant to obtain a uniform Suspension B;

[0068] (4) 200 parts of PAPI are quickly add...

Embodiment 3

[0072] (1) Graphite and red phosphorus prepare a halogen-free composite flame retardant with a weight ratio of 1:1.5; the specific preparation process is as follows:

[0073] Put 4g of expanded graphite, 6g of elemental red phosphorus and 200g of steel balls with a diameter of 6mm into a 100mL steel airtight tank, vacuumize the inside of the airtight tank, and perform ball milling at a ball milling speed of 480rpm for 48 hours to obtain a black powder that is Halogen compound flame retardant;

[0074] (2) Heat 100 parts of BTDA and 200 parts of DMF to 90°C and disperse evenly, add 15 parts of methanol to reflux at 70°C for esterification for 0.5h, and obtain a clear solution A;

[0075] (3) Disperse 15 parts of deionized water, 15 parts of foam stabilizer and 5 parts of composite catalyst in the clarified solution A in step (2) at 60°C, and then add 6 parts of halogen-free composite flame retardant to obtain a uniform Suspension B;

[0076](4) 150 parts of PAPI are quickly a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| solubility (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com