A salt-spray-resistant, aging-resistant water-based paint and preparation method thereof

A water-based coating, aging-resistant technology, applied in antifouling/underwater coatings, anti-corrosion coatings, coatings, etc., can solve the problems of complex synthesis process, poor storage stability of emulsion, low resin grafting efficiency, etc., and achieve acid value. Low, good storage stability, excellent adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

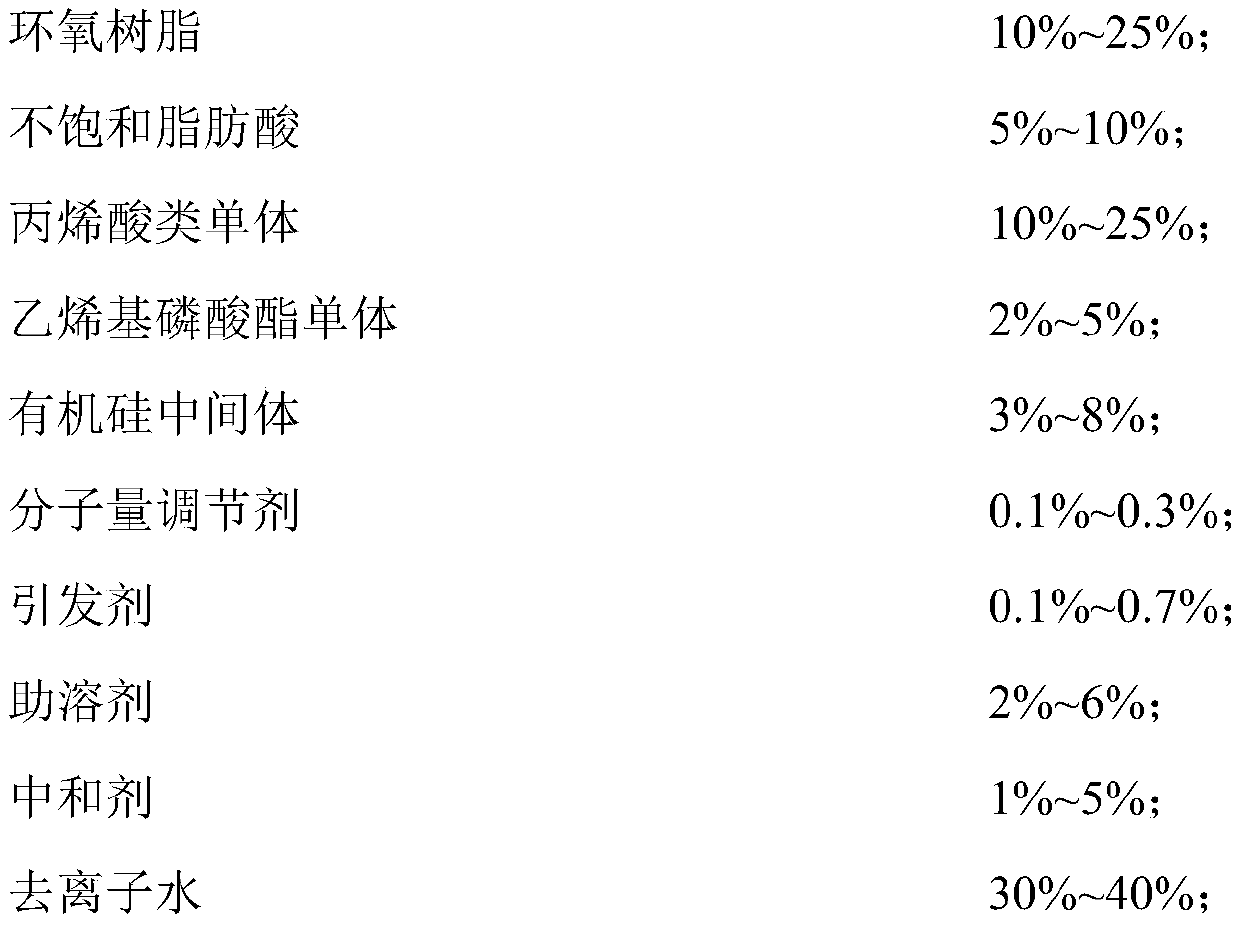

[0031] An embodiment of the salt-spray-resistant and aging-resistant water-based paint and a preparation method thereof of the present invention. The preparation method of this salt-spray-resistant, aging-resistant water-based paint is as follows (each component is by weight percentage):

[0032] (1) Preparation of water-based epoxy ester emulsion

[0033] Add 15% of epoxy resin, 6% of unsaturated fatty acid and 0.2% of molecular weight regulator into the reaction kettle, gradually raise the temperature to 140°C, start stirring after the material melts, raise the temperature to about 190°C, and keep at this temperature for esterification When the acid value is 5mgKOH / g~15mgKOH / g, add 3% unsaturated fatty acid and cool down to 120°C; add 14% acrylic monomer, 2% vinyl phosphate monomer, 5% organic silicon intermediate, initiator Mix 0.5% of the agent evenly, and gradually add it dropwise into the reaction kettle for 5 hours. After the dropwise addition, keep it warm for 3-4 hou...

Embodiment 2

[0038] An embodiment of a salt-spray-resistant and aging-resistant water-based paint and a preparation method thereof of the present invention. The preparation method of this salt-spray-resistant, aging-resistant water-based paint is as follows (each component is by weight percentage):

[0039] (1) Preparation of water-based epoxy ester emulsion

[0040] Add 16% of epoxy resin, 6% of unsaturated fatty acid and 0.2% of molecular weight regulator into the reaction kettle, gradually raise the temperature to 140°C, start stirring after the material melts, raise the temperature to about 190°C, and keep at this temperature for esterification When the acid value is 5mgKOH / g~15mgKOH / g, add 3% unsaturated fatty acid and cool down to 120°C; add 15% acrylic monomer, 3% vinyl phosphate monomer, 5% organic silicon intermediate, initiator Mix 0.5% of the agent evenly, and gradually add it dropwise into the reaction kettle for 5 hours. After the dropwise addition, keep it warm for 3-4 hours...

Embodiment 3

[0045] An embodiment of a salt-spray-resistant and aging-resistant water-based paint and a preparation method thereof of the present invention. The preparation method of this salt-spray-resistant, aging-resistant water-based paint is as follows (each component is by weight percentage):

[0046] (1) Preparation of water-based epoxy ester emulsion

[0047] Add 18% of epoxy resin, 6% of unsaturated fatty acid and 0.2% of molecular weight regulator into the reaction kettle, gradually raise the temperature to 140°C, start stirring after the material melts, raise the temperature to about 190°C, and keep at this temperature for esterification When the acid value is 5mgKOH / g~15mgKOH / g, add 3% unsaturated fatty acid and cool down to 120°C; add 17% acrylic monomer, 3% vinyl phosphate monomer, 5% organic silicon intermediate, initiator Mix 0.5% of the agent evenly, and gradually add it dropwise into the reaction kettle for 5 hours. After the dropwise addition, keep it warm for 3-4 hours...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com