A preparing method of modified cotton fibers, a prepared product and uses

A technology for modifying cotton and cotton fibers, which is applied in the fields of plant fibers, fiber treatment, textiles and papermaking, etc. It can solve the problems of easy deactivation and high living environment requirements, and achieve the effect of eliminating negative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

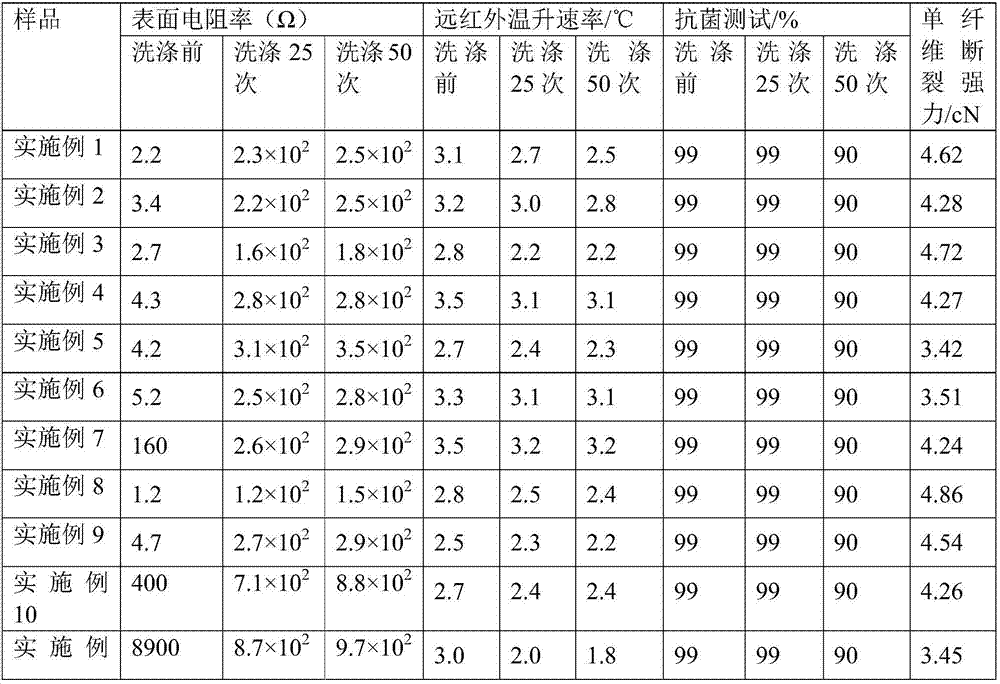

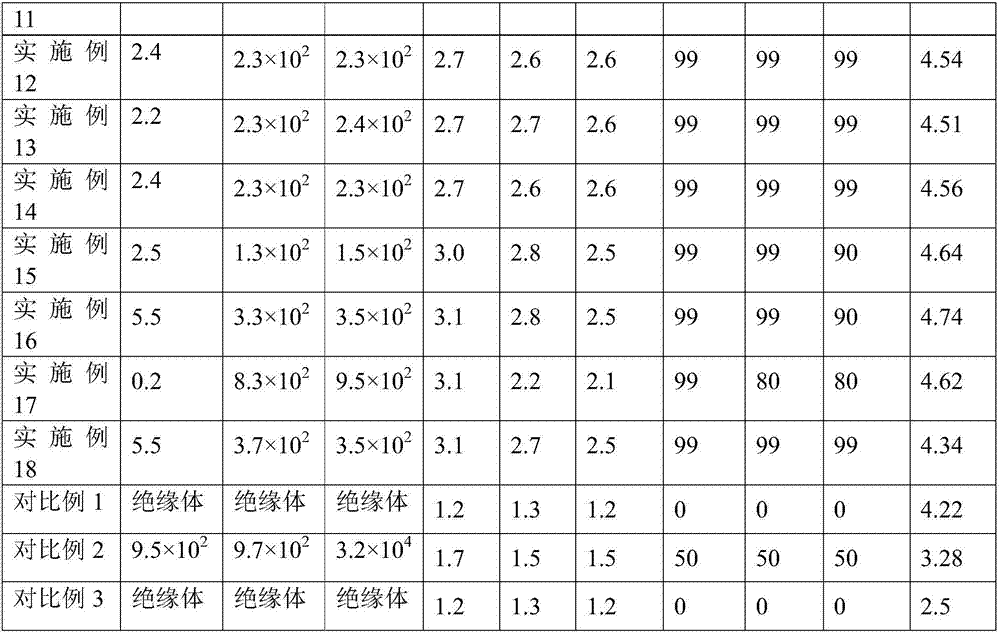

Examples

Embodiment 1

[0056] A kind of preparation method of modified cotton fiber, comprises the steps:

[0057] (1) Sodium hydroxide solution with a concentration of 7g / L was used to impregnate the cotton fibers at 80°C for 20 minutes, and then washed with deionized water until neutral to obtain the treated cotton fibers;

[0058] (2) disperse graphene oxide and sodium sulfate in deionized water to obtain modified slurry, in the modified slurry, the concentration of graphene oxide is 0.1wt%, and the concentration of sodium sulfate is 30g / L;

[0059] (3) Immerse the cotton fiber treated in step (1) in the modified slurry prepared in step (2) according to the bath ratio of 1:100, and immerse it at 40° C. for 50 min to modify it;

[0060] (4) the cotton fiber woven fabric after step (3) is processed carries out following aftertreatment successively:

[0061] Soaking soap treatment: treatment temperature is 80-100°C, time is 10 minutes, soaking liquid contains 2g / L sodium carbonate and 1g / L soap oil...

Embodiment 2-6

[0068] The difference with Example 1 is that in step (1), the alkali treatment temperature and time are respectively 100°C, 10min (Example 2); 90°C, 13min (Example 3); 85°C, 16min (Example 4); 110°C, 7min (Example 5); 70°C, 40min (Example 6).

Embodiment 7-11

[0070] The difference with Example 1 is that in the modified slurry of step (2), the concentration of graphene oxide is respectively 0.05wt% (Example 7); 0.25wt% (Example 8); 1wt% (Example 9) ; 5wt% (Example 10); 6wt% (Example 11).

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com