Intelligent closed type smoke waste heat recycling type gas electromagnetic compound stove

A technology of electromagnetic compounding and flue gas waste heat, which is applied to household stoves/stoves, lighting and heating equipment, etc. It can solve the problems of low thermal efficiency, unused flue gas waste heat, inability to identify pot and boiling, etc. The effect of high scale and heat utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

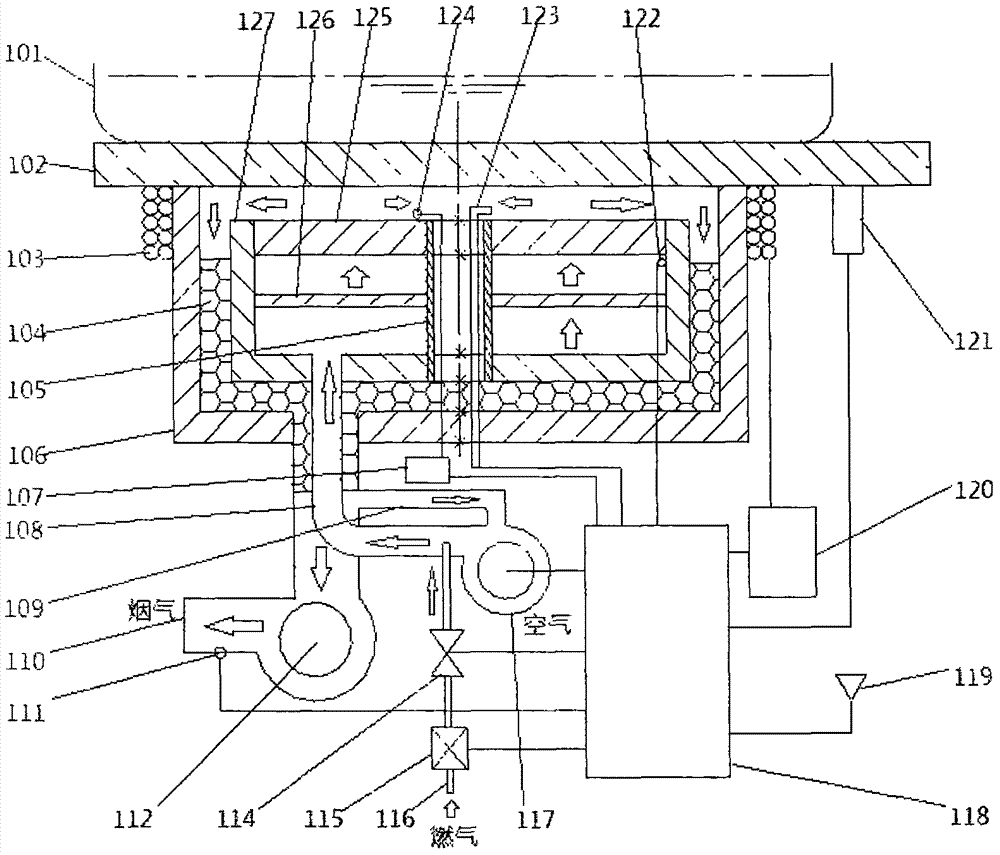

[0034] Embodiment one: figure 1 There is an infrared burning plate (125) with a central round hole and a burner inner chamber (127) with a middle through hole to form a sealed gas burner. 102) A closed combustion chamber is formed. The gas enters from the gas inlet pipe (116), passes through the gas solenoid valve (115) and the gas proportional valve (114), and then enters the air / gas mixing chamber. Driven by the air intake pipe, part of the flue gas is brought in from the flue gas return pipe (109) through the siphon effect, passes through the air / gas mixing chamber (108) and then enters the inner chamber of the burner head (127), and then passes through the equal flow heat exchange After the plate (126), a uniform hot air flow is formed to enter the infrared burning plate (125). The equal flow heat exchange plate (126) is an optional part, and can also be canceled when meeting the requirements of the mixed air flow through proper design.

[0035] After the air / gas mixture...

Embodiment 2

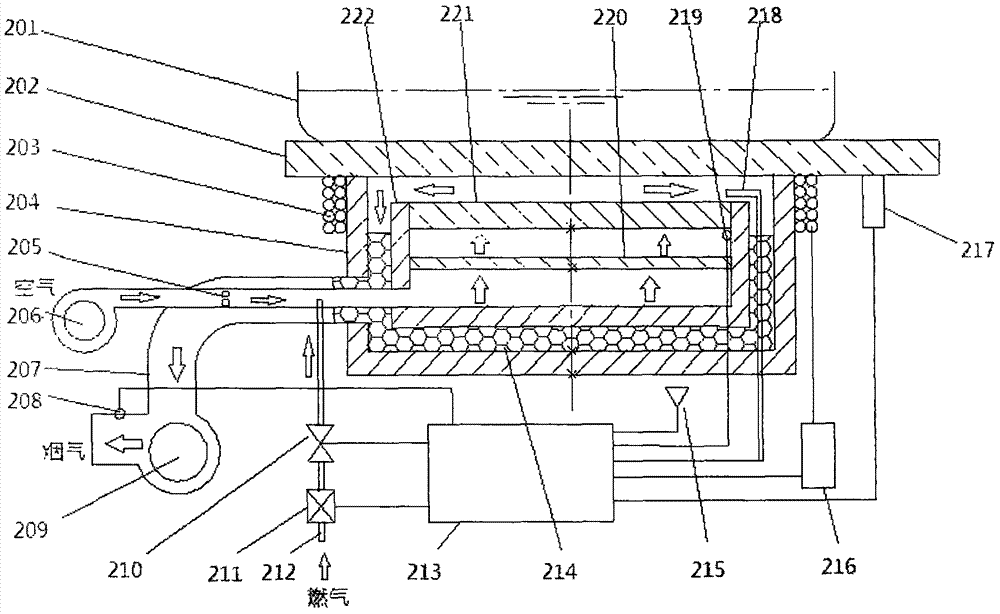

[0049] Embodiment two: figure 2 There is an infrared combustion plate (221) on the whole combustion surface and a burner inner cavity (222) without an intermediate through hole to form a sealed gas burner. In the airtight combustion chamber, the gas enters from the gas inlet pipe (205), passes through the gas solenoid valve (211) and the gas proportional valve (210), and then enters the air / gas mixing chamber. The air inlet of the burner cavity (222) is a horizontal interface, the air intake pipe (205) passes through the middle of the exhaust pipe, and has holes, and the air intake pipe (205) and the exhaust pipe (207) are partly coaxial Driven by the pressure of the air intake fan (206), the air passes through the air intake pipe (205) and uses the hole and siphon effect on the intake pipe to directly bring in part of the flue gas from the exhaust pipe, and after passing through the air / gas mixing chamber Enter the inner cavity of the burner head (222), and then pass throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com