Method for detecting and diagnosing fault in industrial wastewater treatment process based on data model

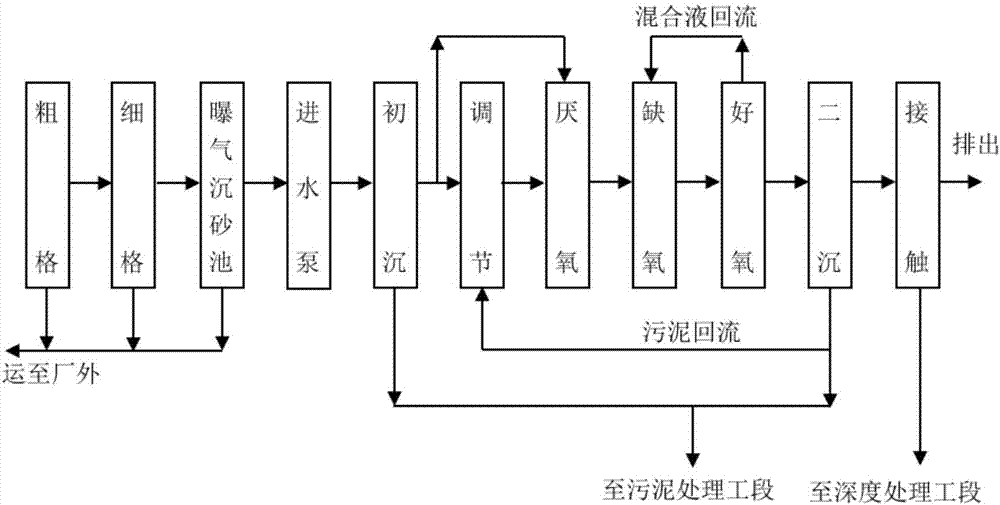

A technology for industrial wastewater and treatment process, which is applied in water treatment parameter control, biological water/sewage treatment, water/sludge/sewage treatment, etc. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

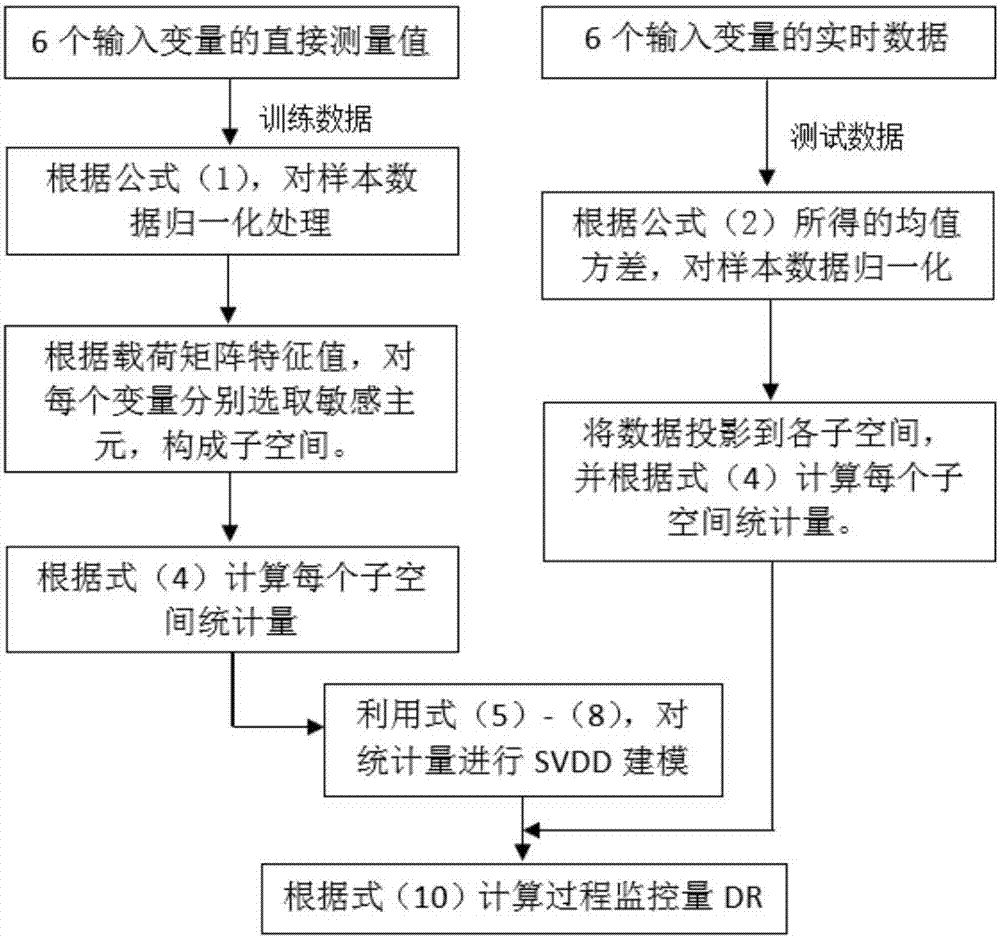

Method used

Image

Examples

Embodiment Construction

[0055] Below by embodiment the present invention will be further described:

[0056] For the six variables, the dissolved oxygen DO(x 1 , mg / L), suspended matter content in aerobic zone SS(x 2 , mg / L), water inlet flow rate Q in (x 3 ,m 3 / s), outlet flow Q ef (x 4 ,m 3 / s), COD in (x 5 , mg / L), and the content of suspended solids in the outlet SS ef (x 6 ,mg / L), collect a set of 100 samples of historical normal data of the system as training data, and a set of real-time process observation data consisting of 100 samples.

[0057] 1. Preprocessing samples

[0058] Perform normalization processing on the first group of data collected above consisting of 200 samples, using formula (1): x 1 The mean value of is 3.78, and the variance is 1.37; x 2 has a mean of 4.00 and a variance of 1.27; x 3 The mean value of is 3417.48, and the variance is 1290.31; x 4 The mean value of is 4090.31, and the variance is 1274.90; x 5 The mean value of is 24.82, and the variance is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com