Energy-saving and corrosion-resistant texture coating and preparation method thereof

A textured coating, corrosion-resistant technology, applied in anti-corrosion coatings, antifouling/underwater coatings, coatings, etc., can solve the problems of low strength, poor weather resistance and corrosion resistance, and poor color retention performance of textured coatings. Wide application range, excellent weather resistance, and the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

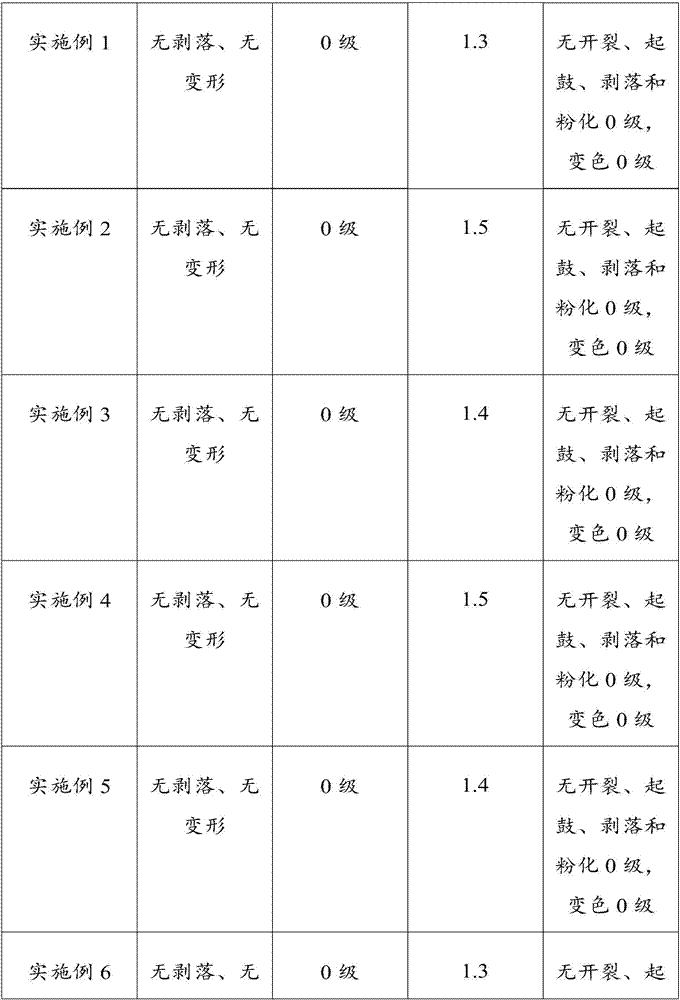

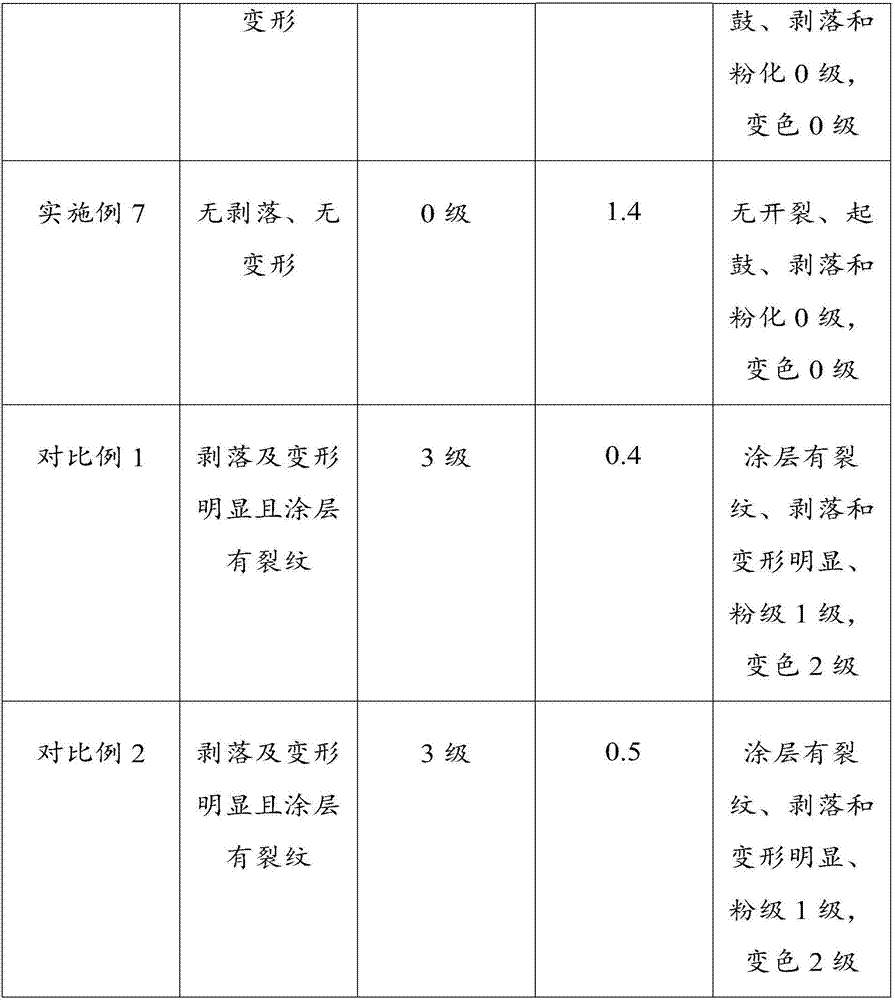

Embodiment 1

[0048] This embodiment provides an energy-saving and corrosion-resistant texture paint, which mainly consists of 50g emulsion, 10g heat insulating agent, 80g filler, 3g antifreeze, 10g dispersant, 1g WC powder and 3g film-forming aid. Among them, the emulsion is mainly made of 50g styrene-acrylic emulsion, 30g vinegar-acrylic emulsion, 10 parts of silicone-cinnamic acid copolymer and 20 parts of polyaniline; the heat insulating agent is polyethylene terephthalate; the antifreeze is Calcium chloride; film-forming aid is dodecyl alcohol ester; filler is colored particles; dispersant is polyacrylamide.

[0049] This embodiment also provides a method for preparing an energy-saving and corrosion-resistant textured coating:

[0050] S1, preparing organosilicon-cinnamic acid copolymer;

[0051] The organosilicon polymer and the cinnamate polymer are physically mixed, wherein the mass content of the organosilicon polymer in the mixture of the organosilicon polymer and the cinnamate p...

Embodiment 2

[0057] This embodiment provides an energy-saving and corrosion-resistant texture paint, which mainly consists of 100g emulsion, 15g heat insulating agent, 120g filler, 10g antifreeze, 3g dispersant, 5g WC powder and 10g film-forming aid. Among them, the emulsion is mainly made of 20g styrene-acrylic emulsion, 10g vinegar-acrylic emulsion, 30 parts of silicone-cinnamic acid copolymer and 10 parts of polyaniline; the heat insulating agent is polyethylene terephthalate and polystyrene The antifreeze is a mixture of calcium chloride and calcium nitrate; the coalescent is a mixture of propylene glycol phenyl ether and ethylene glycol isooctyl ether; the filler is a mixture of titanium dioxide, quartz sand and calcium sand; the dispersant is carboxylate Methylcellulose.

[0058] This embodiment also provides a method for preparing an energy-saving and corrosion-resistant textured coating:

[0059] S1, preparing organosilicon-cinnamic acid copolymer;

[0060] The organosilicon poly...

Embodiment 3

[0066] This embodiment provides an energy-saving and corrosion-resistant texture paint, which mainly consists of 90g emulsion, 40g heat insulating agent, 110g filler, 4g antifreeze, 5g dispersant, 3.5g WC powder and 7g film-forming aid. Among them, the emulsion is mainly made of 45g styrene-acrylic emulsion, 25g vinegar-acrylic emulsion, 12 parts of silicone-cinnamic acid copolymer and 18 parts of polyaniline; the heat insulating agent is nano-scale silicon dioxide powder; the antifreeze agent is 1,3 -Butanediol; the film-forming aid is ethylene glycol butyl ether; the filler is a mixture of colored particles and titanium dioxide; the dispersant is a mixture of carboxymethylcellulose, tannic acid and polyacrylamide.

[0067] This embodiment also provides a method for preparing an energy-saving and corrosion-resistant textured coating:

[0068] S1, preparing organosilicon-cinnamic acid copolymer;

[0069] The organosilicon polymer and the cinnamate polymer are physically mixed, ...

PUM

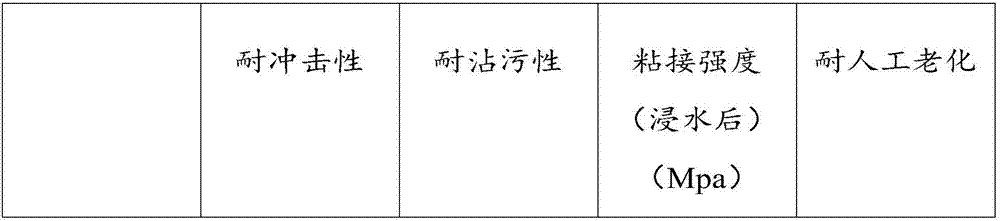

| Property | Measurement | Unit |

|---|---|---|

| Adhesive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com