Waterborne wood celluloid paint suitable for all bottoms and preparation method thereof

A general-purpose, clear paint technology, applied in the field of wood paint, can solve the problems of poor finishing effect of water-based wood paint, insufficient hardness of water-based wood paint, difficult to eliminate foam, etc. Adjustable Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

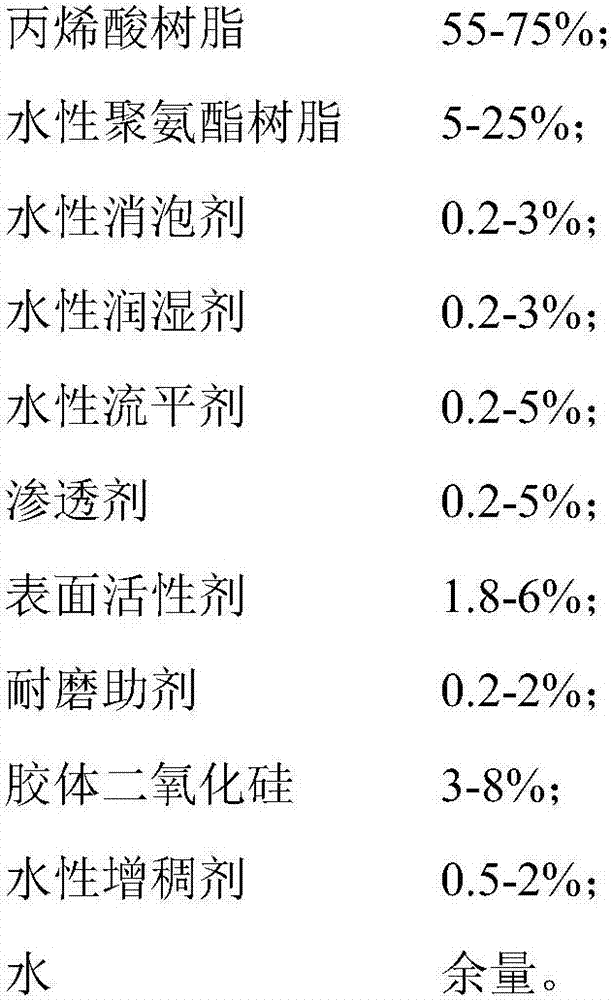

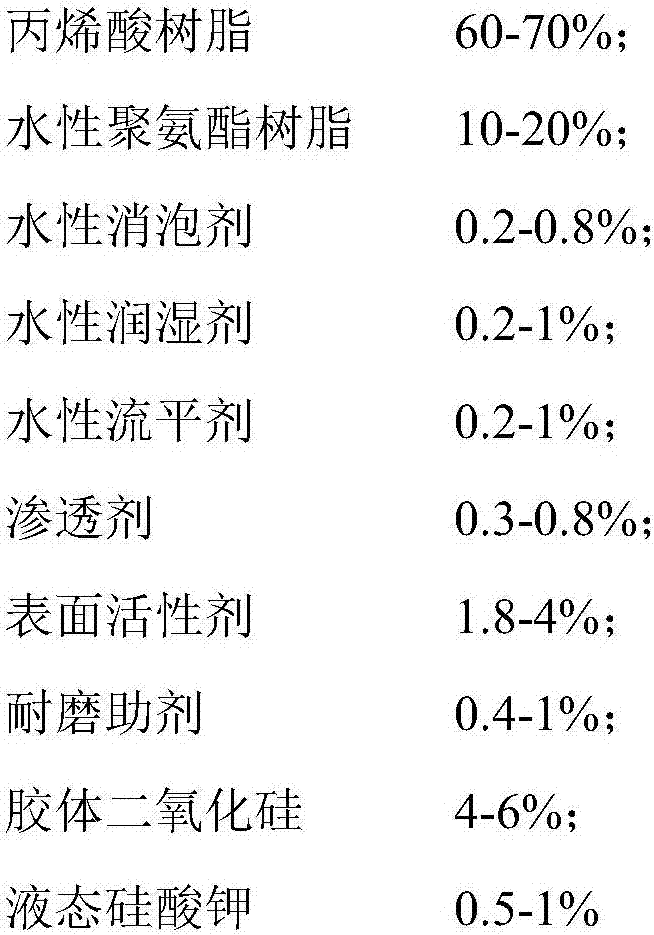

Method used

Image

Examples

Embodiment 1

[0051] Under the condition of rotating speed of 300r / min, take 75kg of Lacper 4509 acrylic resin and 5kg of Ketian Chemical KT600 water-based polyurethane resin into the mixer, then add 0.5kg of TEGO245 water-based wetting agent, 0.4kg of TEGO902W water-based defoamer and 0.3 Kg of TEGO450 water-based leveling agent was mixed and dispersed.

[0052] Raise the rotation speed to 550r / min, add 0.6kg of WT-100 penetrant, 2.2kg of EnviroGem 360 surfactant, 0.7kg of Dow Corning 51 anti-wear aid, 5.5kg of colloidal silicon dioxide and 9.1kg of water, and stir. 10min, reduce the rotation speed to 350r / min, then add 0.8kg of RM2020 water-based thickener, and after stirring evenly, obtain a general-purpose water-based wood clear paint for the bottom surface.

Embodiment 2

[0054] Under the condition of rotating speed of 300r / min, take 70kg of Lacper 4509 acrylic resin and 10kg of Ketian Chemical KT600 water-based polyurethane resin into the mixer, then add 0.4kg of TEGO245 water-based wetting agent, 0.5kg of TEGO902W water-based defoamer and 0.2 Kg of TEGO450 water-based leveling agent was mixed and dispersed.

[0055] Raise the rotation speed to 600r / min, add 0.8kg of WT-100 penetrant, 2.1kg of EnviroGem 360 surfactant, 0.8kg of Dow Corning 51 anti-wear aid, 4.9kg of colloidal silicon dioxide and 9.4kg of water, and stir. 10min, reduce the speed to 350r / min, then add 0.9kg of RM2020 water-based thickener, and after stirring evenly, obtain a general-purpose water-based wood clear paint for the bottom surface.

Embodiment 3

[0057] Under the condition of rotating speed of 300r / min, take 65kg of Lacper 4509 acrylic resin and 15kg of Ketian Chemical KT600 water-based polyurethane resin into the mixer, then add 0.8kg of TEGO245 water-based wetting agent, 0.6kg of TEGO902W water-based defoamer and 0.4 Kg of TEGO450 water-based leveling agent was mixed and dispersed.

[0058] Raise the rotation speed to 580r / min, add 0.7kg of WT-100 penetrant, 1.9kg of EnviroGem 360 surfactant, 1.0kg of Dow Corning 51 anti-wear aid, 4kg of colloidal silicon dioxide and 9.8kg of water, and stir for 10min , reduce the rotation speed to 380r / min, then add 0.8kg of RM2020 water-based thickener, and stir evenly to obtain a general-purpose water-based wood clear paint on the bottom surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| minimum film forming temperature | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com