Constant-transconductance rail-to-rail operational amplifier

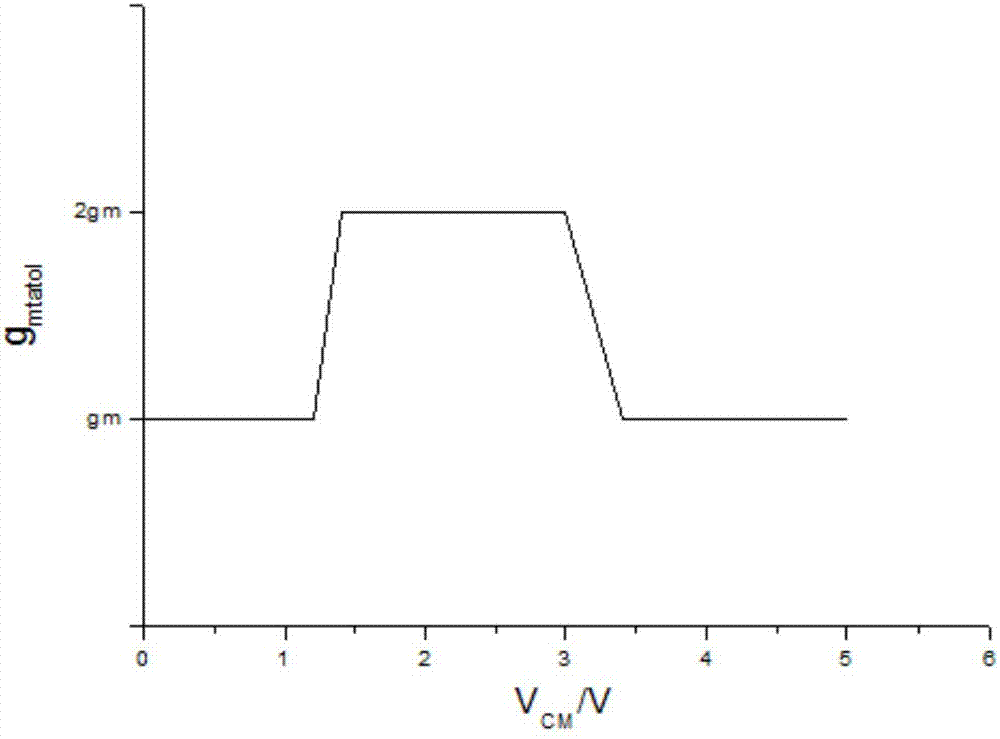

An operational amplifier, full swing technology, used in amplifiers, differential amplifiers, amplifiers with semiconductor devices/discharge tubes, etc., can solve the problems of difficult frequency compensation, non-constant transconductance, etc., to achieve constant equivalent transconductance, The effect of improving common mode rejection ratio and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to deepen the understanding and recognition of the present invention, the present invention will be further described and introduced below in conjunction with the accompanying drawings.

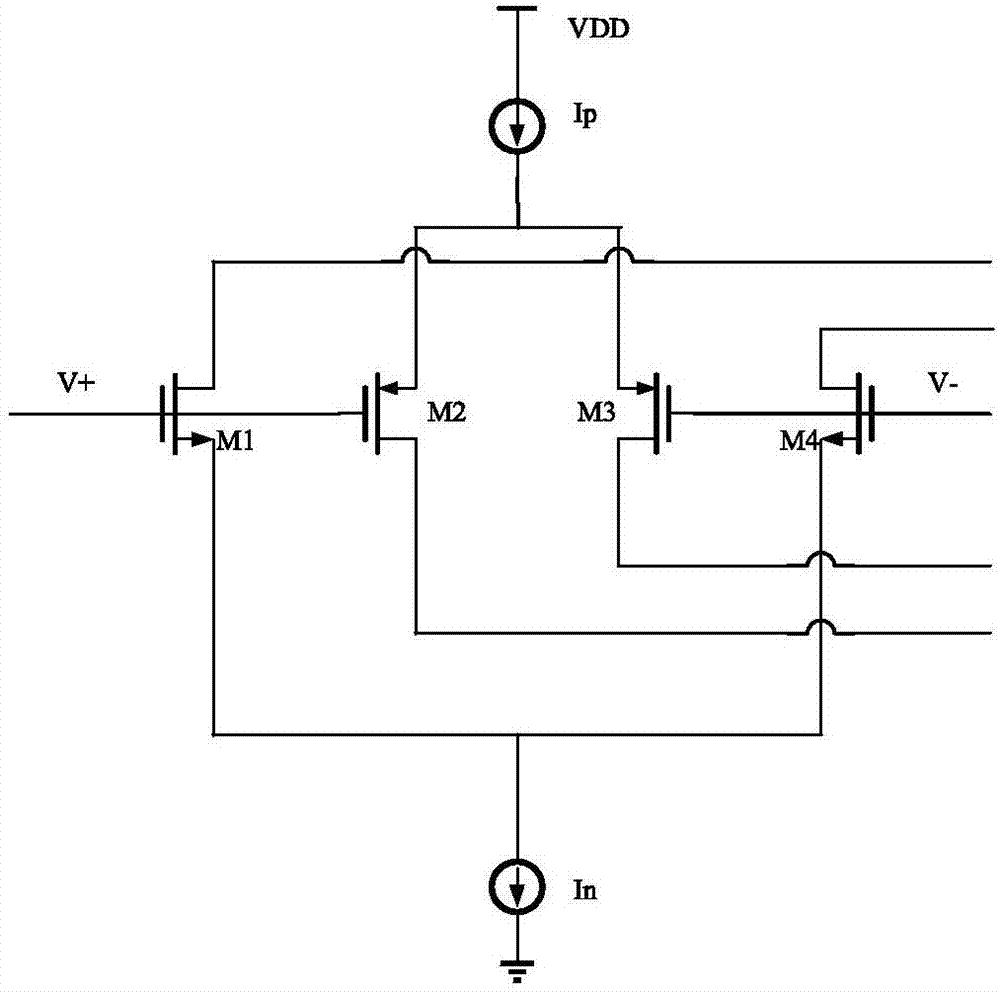

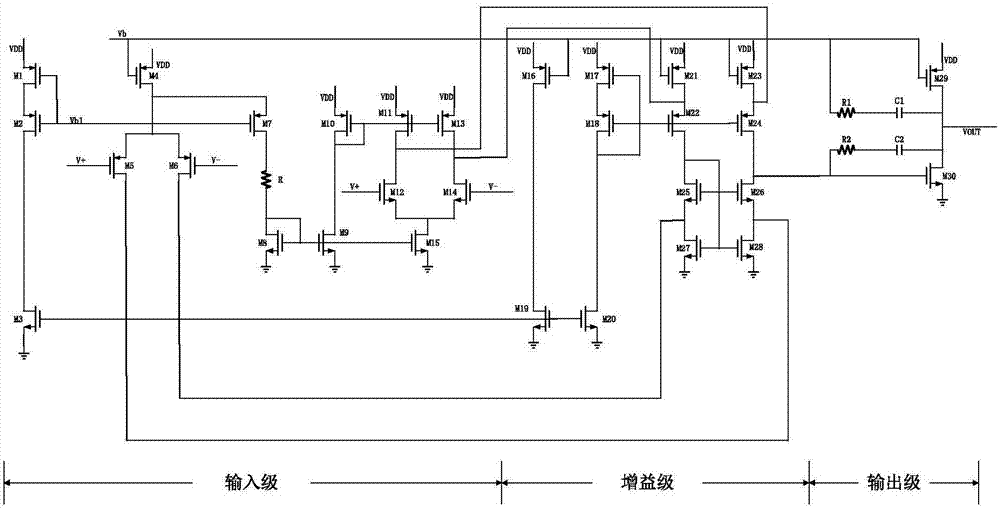

[0019] Such as image 3 and 4 As shown, a constant transconductance full-swing operational amplifier includes a rail-to-rail input stage, a gain stage, and an output stage connected in sequence. The rail-to-rail input stage includes complementary PMOS differential pairs and NMOS differential pairs, PMOS The tail current source of the differential pair and the NMOS differential pair, and the load circuit of the NMOS differential pair. The PMOS differential pair is realized by two PMOS transistors M5 and M6 connected to the common source, wherein the gate of the PMOS transistor M5 is drawn out as an operational amplifier. The non-inverting input terminal, the gate of the PMOS transistor M6 is used as the inverting input terminal of the operational amplifier, and the NMOS differen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com