High-safety lithium-iron-phosphate-type lithium ion battery and preparation method thereof

A lithium-ion battery and lithium iron phosphate technology, applied in the manufacture of electrolyte batteries, secondary batteries, battery electrodes, etc., can solve the problem of affecting the stability between positive and negative electrodes, increasing battery unsafe factors, and affecting the proportion of active materials, etc. problems, to achieve good cycle life characteristics, high energy density, and reduce the amount of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A high-safety lithium iron phosphate lithium-ion battery, the preparation method of which comprises the steps of:

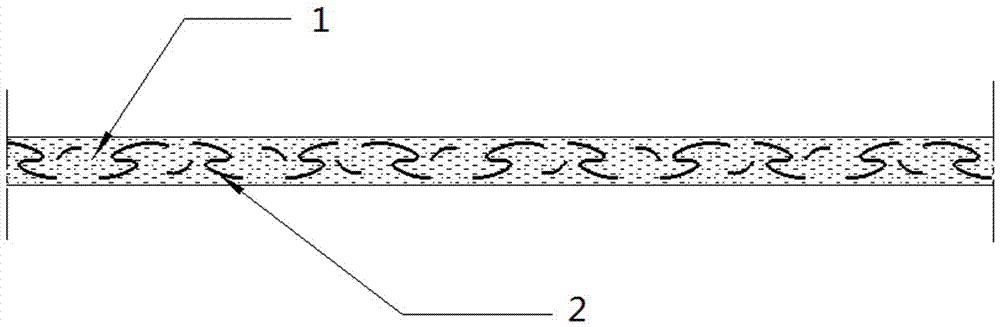

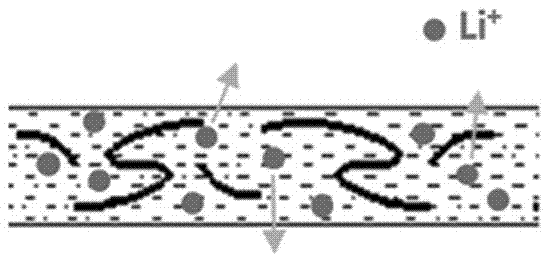

[0039] S1. Send one end of the coiled non-porous steel strip raw material into the perforation system for processing to prepare a three-dimensional strip. The three-dimensional strip includes a metal foil body and flanging holes arranged on the body. The metal foil body is an aluminum strip , the flanging holes are perforated without blanking, and each flanging hole is arranged at an even interval, and the peripheries of the flanging holes in adjacent or adjacent rows respectively protrude toward the two sides of the metal foil body, and the protrusions The top is in the shape of a three-dimensional grid;

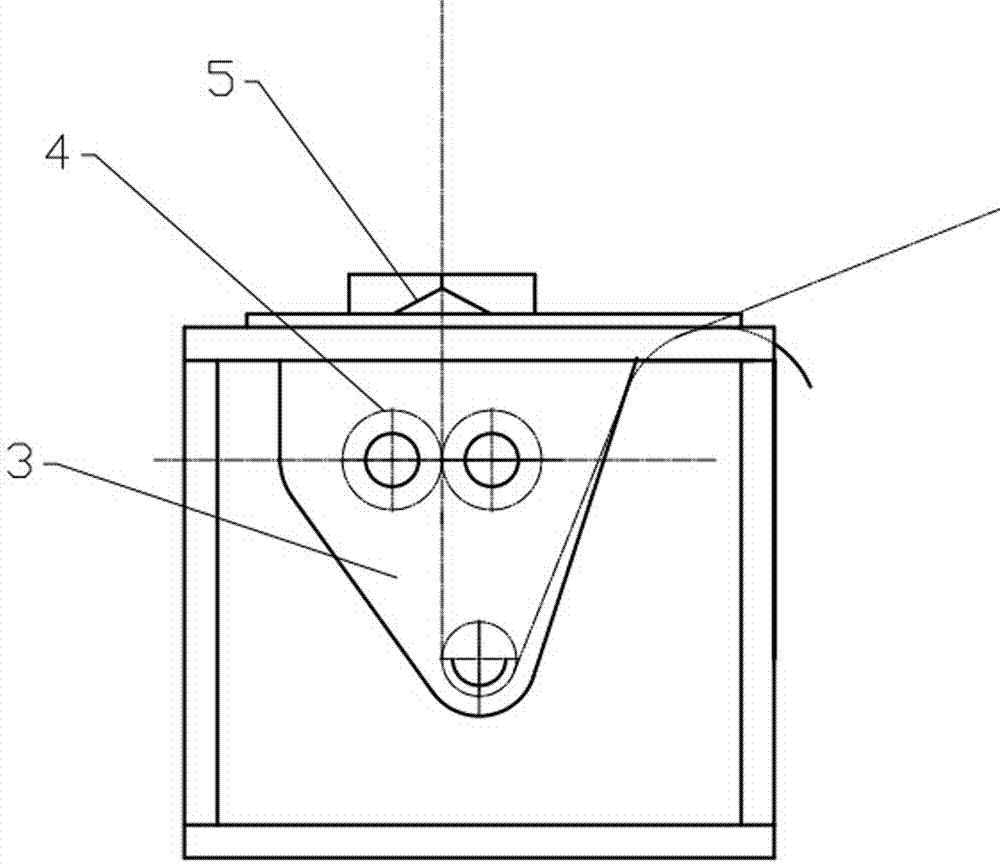

[0040] S2: The three-dimensional belt prepared in step S1 enters the dipping system through the guide wheel for processing, so that the surface of the three-dimensional belt is evenly coated with active material slurry, and then the three-dimensional be...

Embodiment 2

[0047] A high-safety lithium iron phosphate lithium-ion battery, the preparation method of which comprises the steps of:

[0048] S1. Send one end of the non-porous steel strip raw material into a perforation system for processing to prepare a three-dimensional strip. The three-dimensional strip includes a metal foil body and a flanging hole on the body. The metal foil body is a copper strip , the flanging holes are perforated without blanking, and each flanging hole is arranged at an even interval, and the peripheries of the flanging holes in adjacent or adjacent rows respectively protrude toward the two sides of the metal foil body, and the protrusions The top is in the shape of a three-dimensional grid;

[0049] S2: The three-dimensional belt prepared in step S1 enters the dipping system through the guide wheel for processing, so that the surface of the three-dimensional belt is evenly coated with active material slurry, and then the three-dimensional belt passes through th...

Embodiment 3

[0056] A high-safety lithium iron phosphate lithium-ion battery, the preparation method of which comprises the steps of:

[0057] S1. Send one end of the coiled non-porous steel strip raw material into the perforation system for processing to prepare a three-dimensional strip. The three-dimensional strip includes a metal foil body and flanging holes arranged on the body. The metal foil body is an aluminum strip , the flanging holes are perforated without blanking, and each flanging hole is arranged at an even interval, and the peripheries of the flanging holes in adjacent or adjacent rows respectively protrude toward the two sides of the metal foil body, and the protrusions The top is in the shape of a three-dimensional grid;

[0058] S2: The three-dimensional belt prepared in step S1 enters the dipping system through the guide wheel for processing, so that the surface of the three-dimensional belt is evenly coated with active material slurry, and then the three-dimensional be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com