Device and method for purifying bromine trifluoride

A bromine trifluoride and purification method technology, which is applied in the direction of interhalogen compounds, can solve the problem of low product purity, and achieve the effects of high purity, high production efficiency, and high phase separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

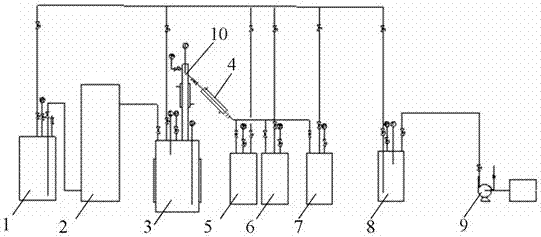

Image

Examples

Embodiment 1

[0051] (ⅰ) After the purification system is cleaned, dried, pumped, and tested for leaks under negative pressure and positive pressure, it is replaced with high-purity nitrogen 5 times without leaking to ensure that there are no impurities other than nitrogen in the system.

[0052] (ii) Evacuate the adsorption tower and rectification tower to below -0.09Mpa, heat the vaporizer to 130°C, heat the adsorption tower to 120°C, evaporate 20kg of bromine trifluoride crude product in the vaporizer, and carry out adsorption purification in the adsorption tower.

[0053] (Ⅲ) After the bromine trifluoride in the vaporizer is completely evaporated, stop the heating of the vaporizer and the adsorption tower, and the bromine trifluoride vapor evaporated in the vaporizer passes through the adsorption tower and then enters the rectification tank to cool at room temperature, and the rectification tank is cooled to room temperature Finally, the rectification tank is evacuated to below -0.09 Mpa...

Embodiment 2

[0057] (ⅰ) After the purification system is cleaned, dried, pumped, and tested for leaks under negative pressure and positive pressure, it is replaced with high-purity nitrogen 5 times without leaking to ensure that there are no impurities other than nitrogen in the system.

[0058] (ii) Evacuate the adsorption tower and rectification tower to below -0.09Mpa, heat the vaporizer to 130°C, heat the adsorption tower to 120°C, evaporate 50kg of bromine trifluoride crude product in the vaporizer, and carry out adsorption purification in the adsorption tower.

[0059] (Ⅲ) After the bromine trifluoride in the vaporizer is completely evaporated, stop the heating of the vaporizer and the adsorption tower, and the bromine trifluoride vapor evaporated in the vaporizer passes through the adsorption tower and then enters the rectification tank to cool at room temperature, and the rectification tank is cooled to room temperature Finally, the rectification tank is evacuated to below -0.09 Mpa...

Embodiment 3

[0063] (ⅰ) After the purification system is cleaned, dried, pumped, and tested for leaks under negative pressure and positive pressure, it is replaced with high-purity nitrogen 5 times without leaking to ensure that there are no impurities other than nitrogen in the system.

[0064] (ii) Evacuate the adsorption tower and rectification tower to below -0.09Mpa, heat the vaporizer to 130°C, heat the adsorption tower to 120°C, evaporate 100kg of bromine trifluoride crude product in the vaporizer, and carry out adsorption and purification in the adsorption tower.

[0065] (Ⅲ) After the bromine trifluoride in the vaporizer is completely evaporated, stop the heating of the vaporizer and the adsorption tower, and the bromine trifluoride vapor evaporated in the vaporizer passes through the adsorption tower and then enters the rectification tank to cool at room temperature, and the rectification tank is cooled to room temperature Finally, the rectification tank is evacuated to below -0.0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com