Low-air-consumption rich nitrogen recycling and nitrogen production apparatus and production method

A nitrogen-enriched, low-altitude technology, applied in the field of nitrogen production equipment, can solve problems such as unadjustable air pressure, waste of nitrogen-rich resources, environmental noise pollution, etc., and achieve the effects of overcoming waste, reducing consumption, and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

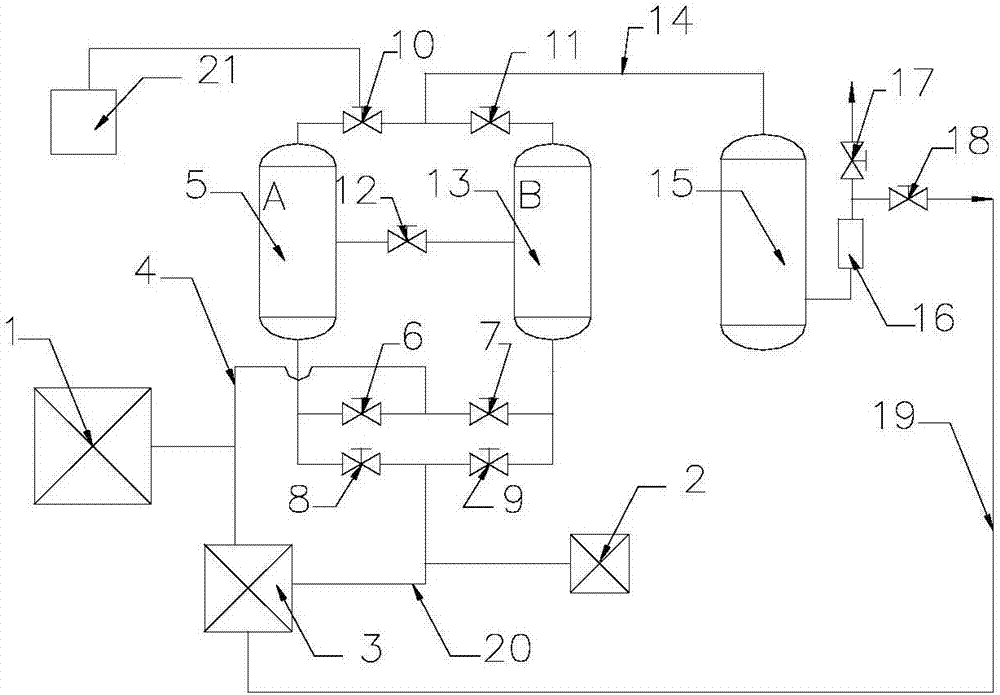

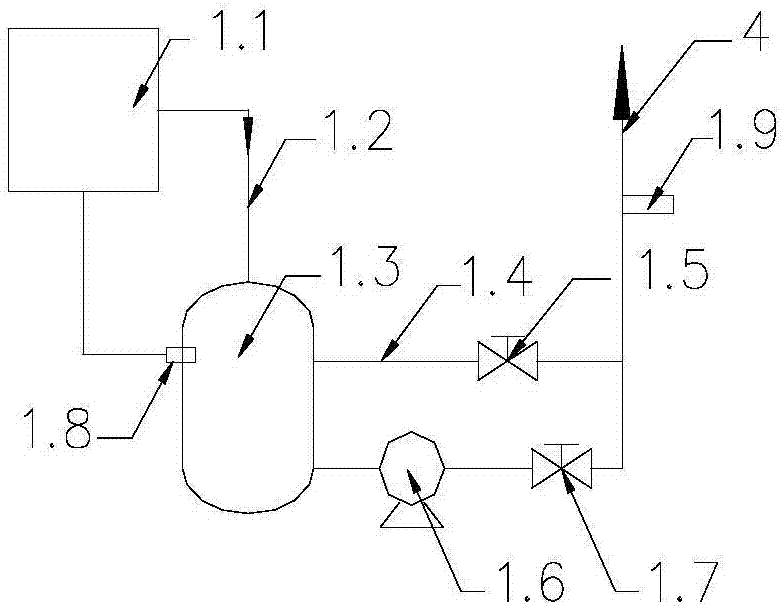

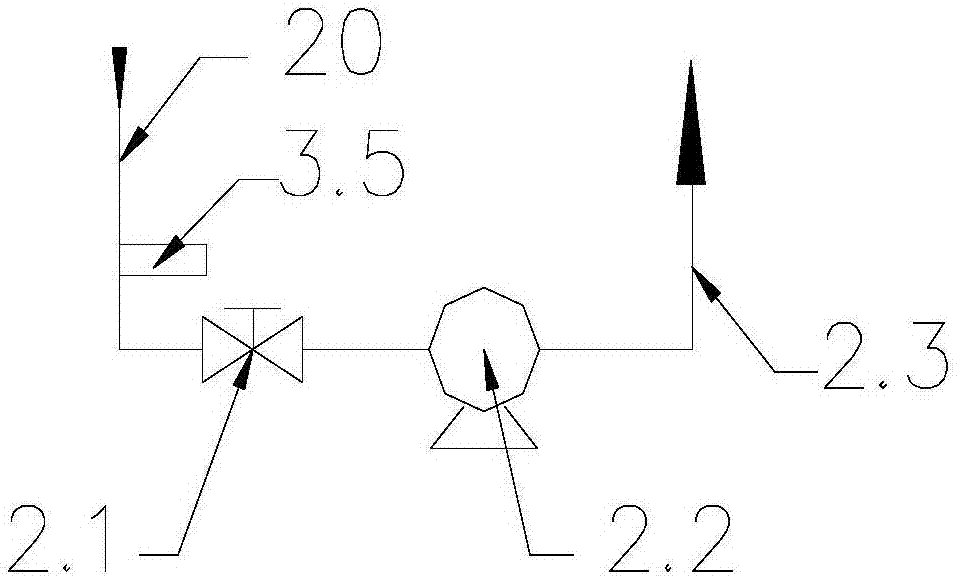

[0047] The invention adopts a low-space consumption nitrogen-enriched recovery nitrogen production device and a preparation method composed of an air pressurization system, a negative pressure analysis system and a nitrogen-enriched recovery system.

[0048] The device adopts an air pressurization system: using the characteristics of molecular sieves that increase with the pressure and increase the adsorption capacity, the air is used to enter the nitrogen production tank to balance and then pressurize again to increase the system pressure and increase the nitrogen production, which can reduce the equipment volume and reduce the investment under the same nitrogen production reduce;

[0049] The device adopts a negative pressure analysis system to refine the analysis process, and the vacuum pump converts the molecular sieve from normal pressure analysis to negative pressure analysis, and further releases the oxygen content adsorbed by the molecular sieve: to improve the subseque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com