Method for separating and extracting chitin from shrimp and crab shells based on degradable ionic liquid

The technology of an ionic liquid and an extraction method, which is applied in the field of waste resource recycling, can solve the problems of existing environment, increased chloride ion to water pollution, strong corrosiveness, etc., and achieves the effect of solving environmental problems and wide industrial application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] In the present embodiment, chitin is separated and extracted by the following method, which specifically includes the following steps:

[0047] (1) Put 0.500g of dried fresh shrimp shells into a 100mL beaker, add 3.0g of 10% citric acid, react for 2 hours, filter to obtain a decalcified shrimp shell and a citric acid filtrate, and then add 1.5g of citric acid 6% citric acid, reacted for 1 hour, filtered to obtain the second decalcified shrimp shell and the second citric acid filtrate, placed the first citric acid filtrate and the second citric acid filtrate respectively, and added 0.005g calcium citrate seed crystals respectively, for 10 hours Finally, calcium citrate is precipitated, totaling 0.1622g, and the calcium removal rate is over 99%. The filtrates after filtering out calcium citrate are combined and supplemented with 1.200g of 10% citric acid solution, which can be recycled.

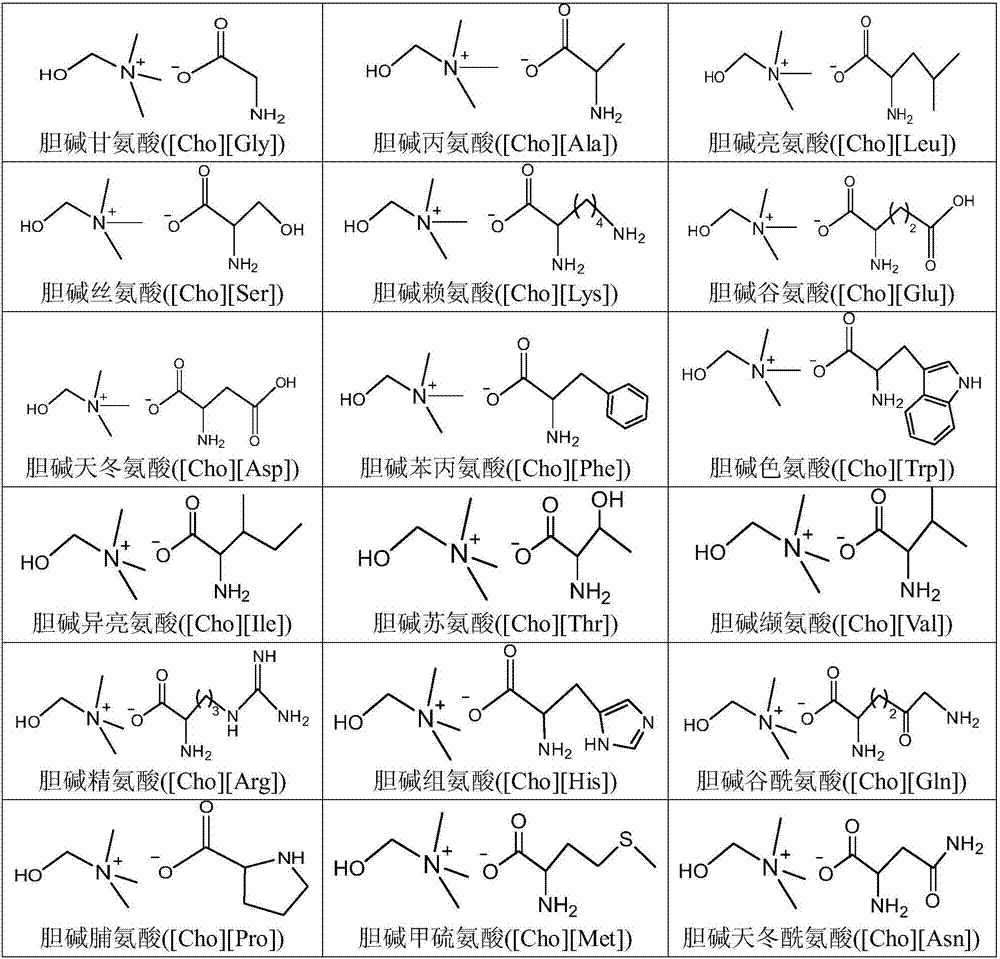

[0048] (2) Dissolve decalcified shrimp shells with 5 g of cholinealanine ([Cho][Ala]...

Embodiment 2

[0050] The difference from Example 1 is that the secondary citric acid filtrate and secondary citric acid filtrate are obtained by filtering in step (1), and the primary citric acid filtrate and the secondary citric acid filtrate are respectively placed, and 0.0025g calcium citrate is added respectively The seed crystals precipitated calcium citrate after 10 hours, amounting to 0.1422g, and the calcium removal rate was over 99%; except that the method used and the selection of other conditions were the same as in Example 1.

Embodiment 3

[0052] The difference with Example 1 is that when dissolving the shrimp shells and dissolving the second decalcification shrimp shells in step (1), the 10% citric acid solution that is used is 3g. In addition, the method used and the selection of other conditions All the same as in Example 1, 0.1320g of calcium citrate was precipitated, and the calcium removal rate was more than 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com