Preparation method of TiO2/cellulose nano-composite film, composite film, and application of composite film

A nano-composite and cellulose technology, applied in the field of functional materials, can solve the problems of poor adsorption capacity and achieve the effect of maintaining activity, uniform distribution of two phases, and excellent adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment one: a kind of TiO provided by the present invention 2 / The preparation method of cellulose nanocomposite membrane comprises the following steps, (1) adopting sol-gel method to prepare TiO 2 Sol: use dimethylacetamide DMAC solvent system, glacial acetic acid as chelating agent to prepare TiO 2 Sol;

[0023] (2) Select pineapple leaf cellulose as the cellulose matrix, soak the pineapple leaf cellulose in pure water and stir, then add methanol to soak and stir, then use dimethylacetamide DMAC to exchange methanol to activate the pineapple leaf cellulose; Good cellulose is dissolved in the LiCl / dimethylacetamide DMAC system solution to obtain a homogeneous cellulose solution;

[0024] (3) The composite membrane was prepared by liquid homogeneous forming method.

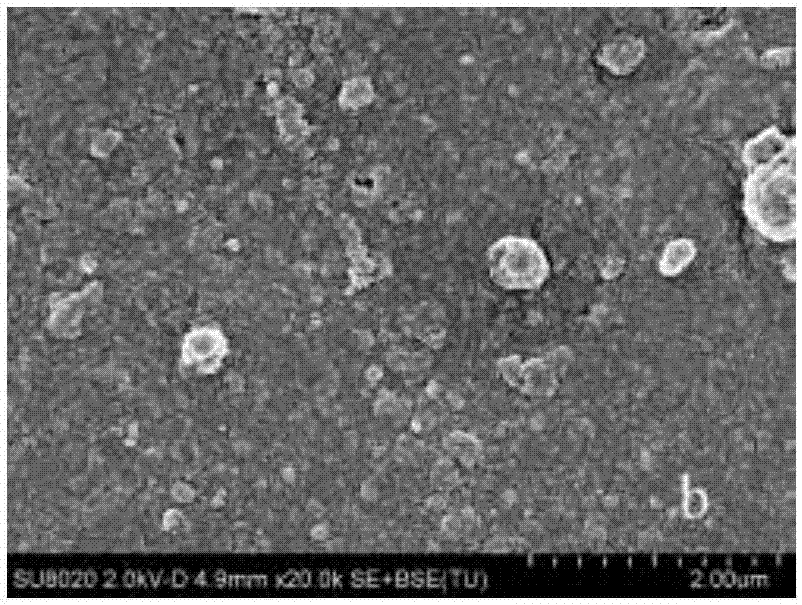

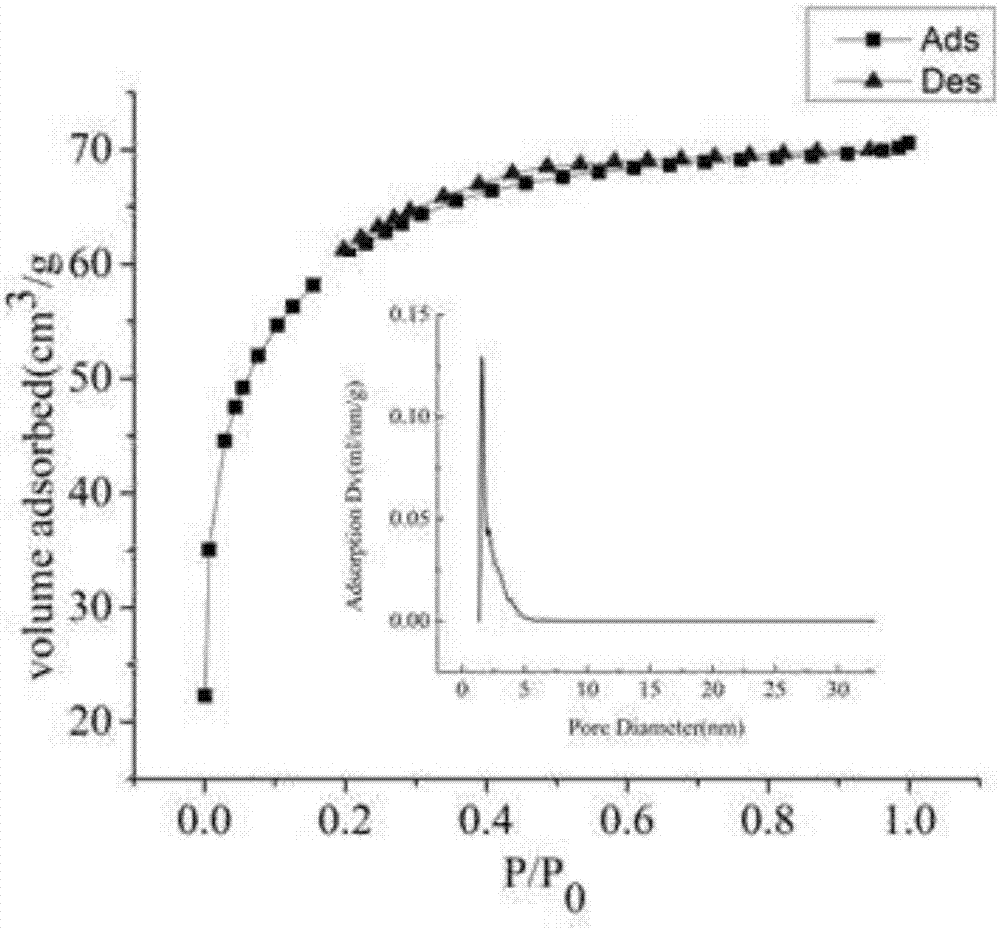

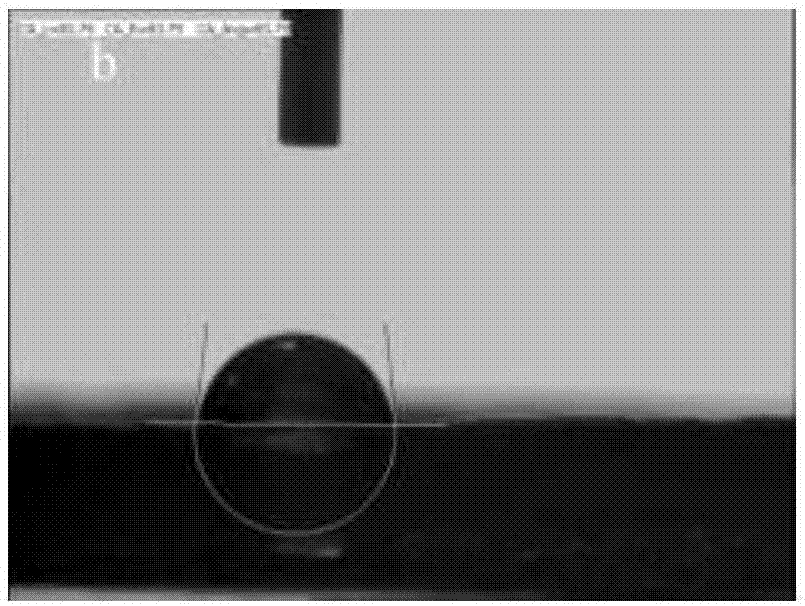

[0025] Its performance of the composite membrane that the present invention obtains is as Figure 1-3 as shown, figure 1 It is the SEM map of the composite film. It can be seen from the figure that...

Embodiment 2

[0026] Embodiment two: a kind of TiO provided by the present invention 2 / The preparation method of cellulose nanocomposite membrane comprises the following steps, (1) adopting sol-gel method to prepare TiO 2 Sol: use dimethylacetamide DMAC solvent system, glacial acetic acid as chelating agent to prepare TiO 2 Sol;

[0027] (2) Select pineapple leaf cellulose as the cellulose matrix, soak the pineapple leaf cellulose in pure water and stir, then add methanol to soak and stir, then use dimethylacetamide DMAC to exchange methanol to activate the pineapple leaf cellulose; Good cellulose is dissolved in the LiCl / dimethylacetamide DMAC system solution to obtain a homogeneous cellulose solution;

[0028] (3) The composite membrane was prepared by liquid homogeneous forming method.

[0029] Further, TiO is prepared in the step (1) 2 The specific method of the sol includes: mixing tetrabutyl titanate and dimethylacetamide DMAC at a molar ratio of 1:1, adding glacial acetic acid t...

Embodiment 3

[0035] Embodiment three: a kind of TiO provided by the present invention 2 / The preparation method of cellulose nanocomposite membrane comprises the following steps, (1) adopting sol-gel method to prepare TiO 2 Sol: use dimethylacetamide DMAC solvent system, glacial acetic acid as chelating agent to prepare TiO 2 Sol;

[0036](2) Select pineapple leaf cellulose as the cellulose matrix, soak the pineapple leaf cellulose in pure water and stir, then add methanol to soak and stir, then use dimethylacetamide DMAC to exchange methanol to activate the pineapple leaf cellulose; Good cellulose is dissolved in the LiCl / dimethylacetamide DMAC system solution to obtain a homogeneous cellulose solution;

[0037] (3) The composite membrane was prepared by liquid homogeneous forming method.

[0038] Further, TiO is prepared in the step (1) 2 The specific method of the sol includes: mixing tetrabutyl titanate and dimethylacetamide DMAC at a molar ratio of 1:1, adding glacial acetic acid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com