Preparation method of composite ground crosslinking acid controllable in crosslinking time

A technology of crosslinking time and composite crosslinking agent, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of uncontrollable crosslinking time and achieve controllability, strong sand-carrying ability, good The effect of heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055]This example is the Bin 105-17 well in the Bin 105 block of the Shengli Oilfield. -3 μm 2 , average permeability 62×10 -3 μm 2 , is a low porosity-medium porosity, ultra-low permeability-low permeability reservoir, the porosity distribution is between 14.6-21.7%, and the average porosity is 17.5%. The main reservoir lithology is mainly argillaceous aphanitic limestone, The average limestone content is about 50%. It has the characteristics of low porosity-medium porosity, ultra-low permeability-low permeability and complex lithology. The buried depth of the reservoir is 2700-2900m. 120°C.

[0056] Prepare the ground composite cross-linking acid with controllable cross-linking time as follows:

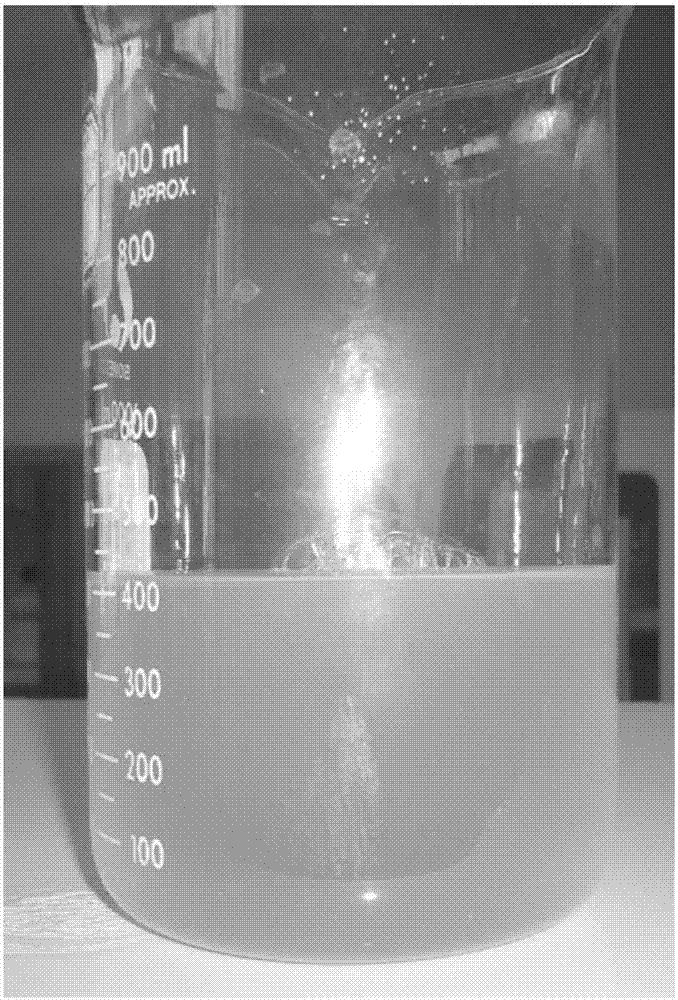

[0057] (1) Preparation of polymer thickened acid: Prepare 1L of 15% hydrochloric acid with tap water and add it to the reaction vessel, slowly add 5.0 g of high molecular weight polymer while stirring, and continue to stir to make it fully dissolved, leave it for 2 hours, under...

Embodiment 2

[0076] Ground Crosslinking Acid Preparation:

[0077] (1) Preparation of polymer thickened acid: Prepare 1L of 15% hydrochloric acid with distilled water, add it to a three-necked flask with stirring and a thermometer, slowly add 4.0g of high molecular polymer while stirring, and continue stirring to fully dissolve it, place 2 hours, add 1.7g carboxymethyl hydroxypropyl guar gum under stirring condition, continue to stir until uniform, stand-by.

[0078] (2) Preparation of organic composite crosslinking agent: Weigh 10.7g of propyl titanate tetraacetate and add it into a three-necked flask equipped with a condenser tube, a thermometer, and a stirrer, and add 24.5g of diethanolamine while raising the temperature. , react for 40 minutes, raise the temperature to 65°C and start distillation, keep the distillation temperature at 75-78°C, when the distillate volume reaches 6.4mL, add methanol after cooling down to below 60°C, stir well and set aside.

[0079] (3) Preparation of cr...

Embodiment 3

[0083] Ground Crosslinking Acid Preparation:

[0084] Ground Crosslinking Acid Preparation:

[0085] (1) Preparation of polymer thickened acid: prepare 1000mL of 20% hydrochloric acid with distilled water, add it to a three-necked flask with stirring and a thermometer, slowly add 5.0g of high molecular polymer while stirring, and continue to stir to fully dissolve it, place 2 hours, set aside.

[0086] (2) Preparation of organometallic cross-linking agent: add 6.2 g of propyl titanate tetraacetate into a three-necked flask equipped with a condenser, a thermometer, and a stirrer, stir to make it fully dissolve, slowly add 14.0 g of triethanolamine, at 90 ° C, React for 4 hours, drop to normal temperature and discharge.

[0087] (3) Preparation of cross-linking accelerator: In a three-necked flask with a condenser, a thermometer, and a stirrer, add 79.2g of formalin, control the temperature below 30°C, add 19.1g of catechol, and slowly heat up to 40°C , add 0.05g sodium hydro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Permeability | aaaaa | aaaaa |

| Average permeability | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com