Waste mineral oil catalytic cracking comprehensive utilization system and processing process thereof

A catalytic cracking, waste mineral oil technology, applied in the petroleum industry, only multi-stage series refining and cracking process treatment, treatment of hydrocarbon oil, etc., can solve the problem of high production costs, achieve energy saving, broad application prospects, and application broad effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

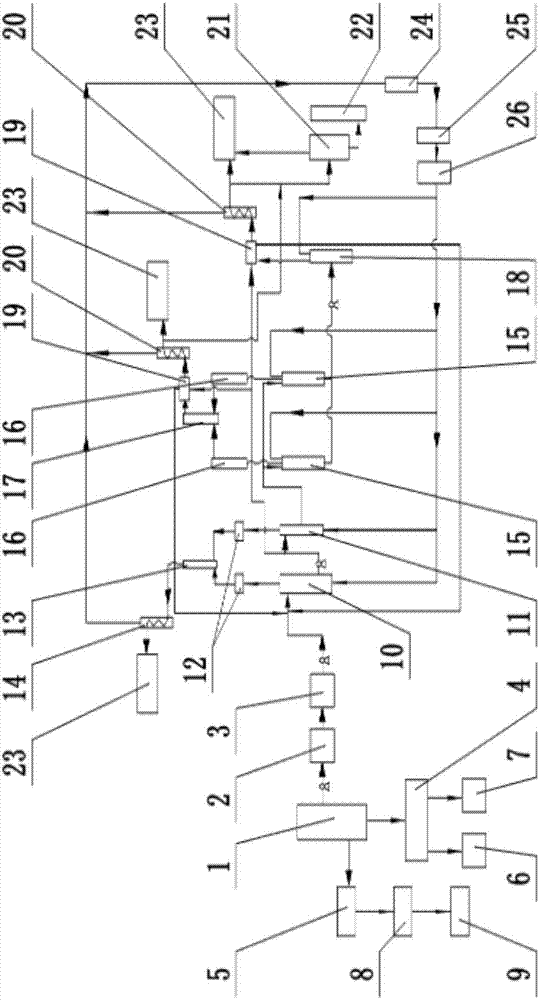

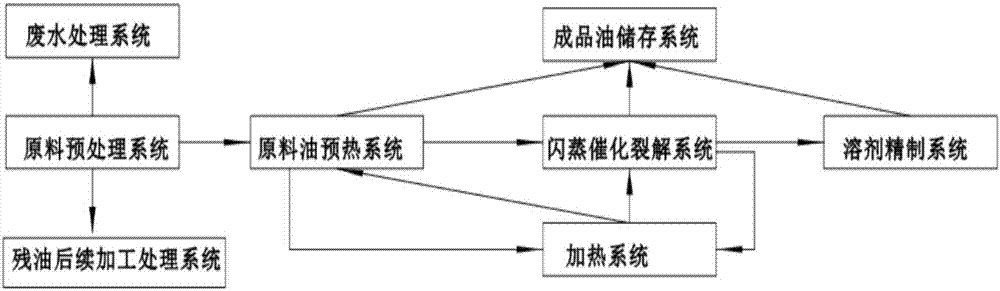

[0044] like figure 1 and figure 2 As shown, a waste mineral oil catalytic cracking comprehensive utilization system includes a raw material pretreatment system, a raw material oil preheating system, a flash catalytic cracking system, a solvent refining system, a product oil storage system, a heating system, and a residual oil subsequent processing system It is connected to the waste water treatment system, raw material pretreatment system, raw oil preheating system, flash catalytic cracking system and solvent refining system in sequence, and the raw material pretreatment system is respectively connected to the residual oil subsequent processing system and the waste water treatment system. The heating system It is connected with the raw material oil preheating system and flash catalytic cracking system, and the raw material oil preheating system, flash catalytic cracking system and solvent refining system are all connected with the product oil storage system.

[0045] The raw...

specific Embodiment 2

[0073] like figure 1 and figure 2 As shown, a waste mineral oil catalytic cracking comprehensive utilization system includes a raw material pretreatment system, a raw material oil preheating system, a flash catalytic cracking system, a solvent refining system, a product oil storage system, a heating system, and a residual oil subsequent processing system It is connected to the waste water treatment system, raw material pretreatment system, raw oil preheating system, flash catalytic cracking system and solvent refining system in sequence, and the raw material pretreatment system is respectively connected to the residual oil subsequent processing system and the waste water treatment system. The heating system It is connected with the raw material oil preheating system and flash catalytic cracking system, and the raw material oil preheating system, flash catalytic cracking system and solvent refining system are all connected with the product oil storage system.

[0074] The raw...

specific Embodiment 3

[0102] like figure 1 and figure 2 As shown, a waste mineral oil catalytic cracking comprehensive utilization system includes a raw material pretreatment system, a raw material oil preheating system, a flash catalytic cracking system, a solvent refining system, a product oil storage system, a heating system, and a residual oil subsequent processing system It is connected to the waste water treatment system, raw material pretreatment system, raw oil preheating system, flash catalytic cracking system and solvent refining system in sequence, and the raw material pretreatment system is respectively connected to the residual oil subsequent processing system and the waste water treatment system. The heating system It is connected with the raw material oil preheating system and flash catalytic cracking system, and the raw material oil preheating system, flash catalytic cracking system and solvent refining system are all connected with the product oil storage system.

[0103] The raw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com