Preparation method of metal atom-doped large-area regular epitaxial graphene

A technology of metal atoms and graphene, applied in graphene, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems affecting electrical characteristics and destroying the flatness of graphene sheets, so as to achieve controllable doping types and ideas Effects of clear and simplified growth and doping processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

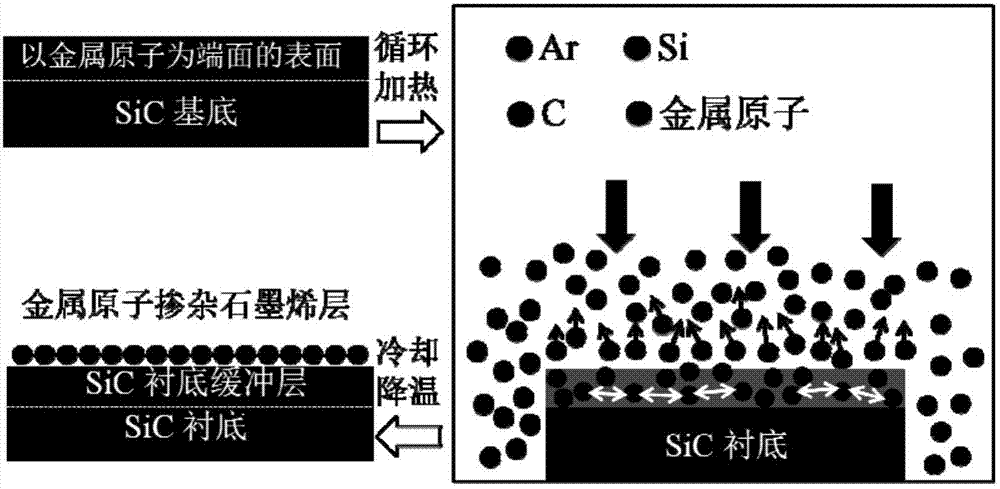

Method used

Image

Examples

Embodiment 1

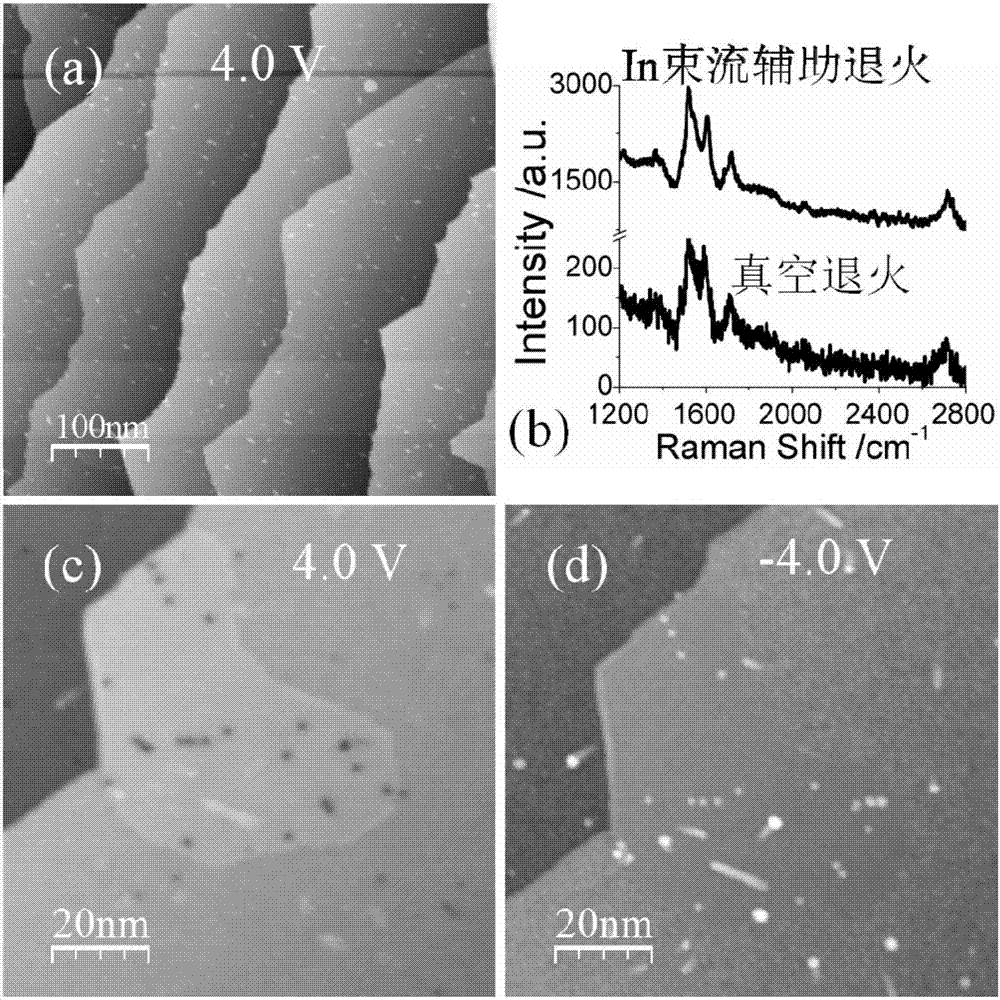

[0034] The single crystal 6H-SiC(0001) sample was heated to about 540°C for 8 hours under 0.5A direct current; using the K-Cell device, the metal In source was heated to 700°C, the heating current was 2.8A, and the In atoms The beam size was controlled at 26nA; at the same time, the SiC sample was heated to 1100°C with a current of 1.1A, and heated and annealed under the In beam for 10min, and the surface temperature of the sample was monitored and controlled by an infrared thermometer; after cooling to room temperature, the Ar The atmosphere was passed into the sample preparation chamber and the vacuum was maintained at 5 × 10 -5 Torr; use a current of 1.8A to raise the temperature of the sample to 1450°C and heat and anneal for 5 minutes, then reheat after cooling for 2 minutes, and repeat this cycle 5 times; in this example, a large-area regular epitaxial graphene doped with metal In atoms was obtained, and its scanning Tunneling microscope morphology and Raman test results...

Embodiment 2

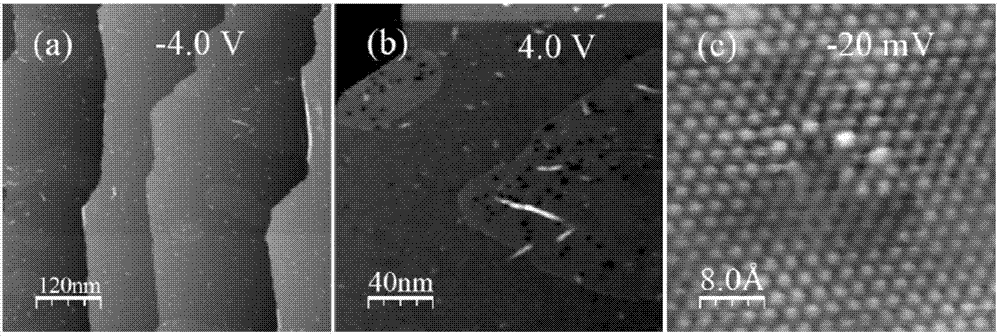

[0036]The single crystal 6H-SiC(0001) sample was heated to 550°C for 8 hours under the direct current condition of 0.51A; using the K-Cell device, the metal Ag source was heated to 730°C, the heating current was 3.0A, and the Ag atom beam The current size is controlled at 30nA; at the same time, the SiC sample is heated to 1100°C with a current of 1.15A, heated and annealed for 10 minutes, and the surface temperature of the sample is monitored and controlled by an infrared thermometer; after the annealing is completed and cooled to room temperature, the Ar atmosphere is introduced into the sample preparation chamber, and maintain a vacuum of 5 x 10 -5 Torr; use a current of 1.9A to heat the sample to 1450°C for 5 minutes, heat it after cooling for 2 minutes, and recycle 4 times; this example prepares a large-area regular epitaxial graphene doped with metal Ag atoms, and its scanning tunnel Microscopic morphology and atomic resolution images such as image 3 shown.

Embodiment 3

[0038] The single crystal 6H-SiC(0001) sample was heated to 530°C for 8h under DC condition of 0.48A; using the K-Cell device, the metal Bi source was heated to 710°C, the heating current was 2.6A, and the Bi atomic beam The current size is controlled at 24nA; at the same time, the SiC sample is heated to 1130°C with a current of 1.2A and heated and annealed for 10min, and the surface temperature of the sample is monitored and controlled by an infrared thermometer; after cooling to room temperature, the Ar atmosphere is introduced into the sample preparation chamber, and maintain a vacuum of 5 x 10 - 5 Torr; use a current of 1.8A to raise the temperature of the sample to 1450°C and heat and anneal for 5 minutes, then cool for 2 minutes and then reheat, and so cycle 4 times; this example obtained a large-area regular epitaxial graphene doped with metal Bi atoms, which Scanning tunneling microscope morphology and atomic resolution images such as Figure 4 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com