Alloy bonding wire of gold, silver and palladium and preparation method thereof

A technology of alloy bonding and wire, which is applied in semiconductor/solid-state device manufacturing, circuits, electric solid-state devices, etc., can solve problems such as no technological breakthroughs, achieve good performance, improve processing performance, and meet performance and quality requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

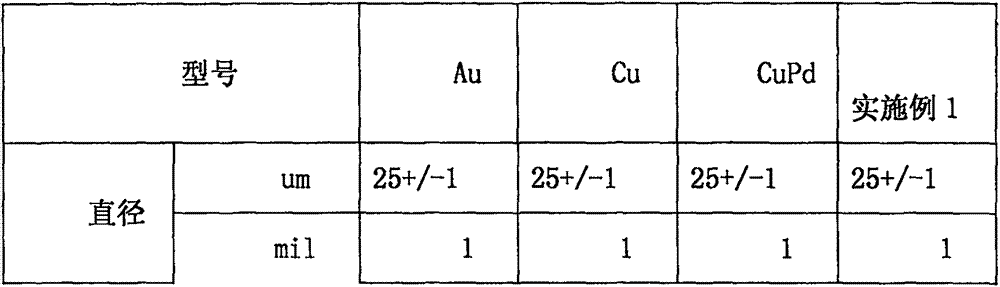

[0021] An alloy bonding wire of gold, silver and palladium, including gold element, silver element, palladium element and impurities, the mass fraction of gold element accounting for the total mass is 5%, the mass fraction of palladium element accounting for the total mass is 15%, silver The mass fraction of elements in the total mass is 80%, and the impurities are zero.

[0022] The preparation method of the alloy bonding wire of described gold, silver and palladium, concrete steps are as follows:

[0023] Step 1, weighing raw materials: weighing gold with a purity of 99.999% or more, silver with a purity of 99.999% or more, and palladium with a purity of 99.99% or more;

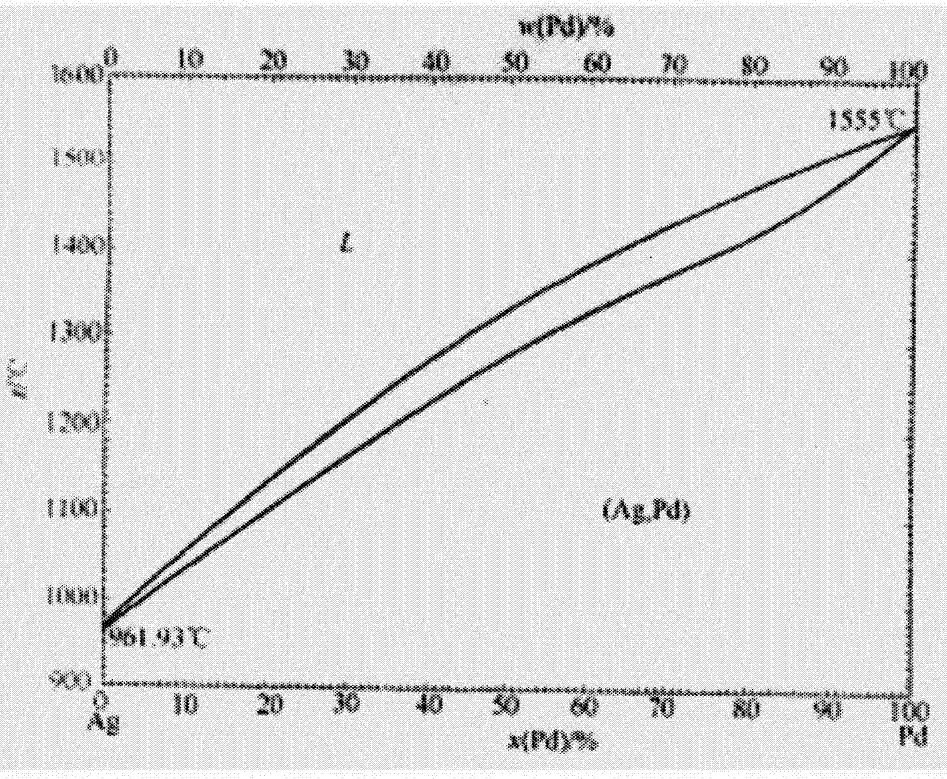

[0024] Step 2, preparing the alloy; in a vacuum of 0.1*10 -3 Prepare silver-palladium pre-alloy under the environment of pa and 1600 ℃, this vacuum degree can lower the melting point of pre-alloy;

[0025] Step 3, melting and casting: in a vacuum of 1*10 -3 Refining at 1300°C for 30 minutes in an interme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com