Processing process for obtaining nanosheet composite material through ultrasonic rolling

A composite material and processing technology, applied in nanotechnology, metal processing equipment, transportation and packaging, etc., can solve problems such as difficulty in uniform dispersion and easy agglomeration of nanoparticles, and achieve the effect of expanding the scope of application and improving the combination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

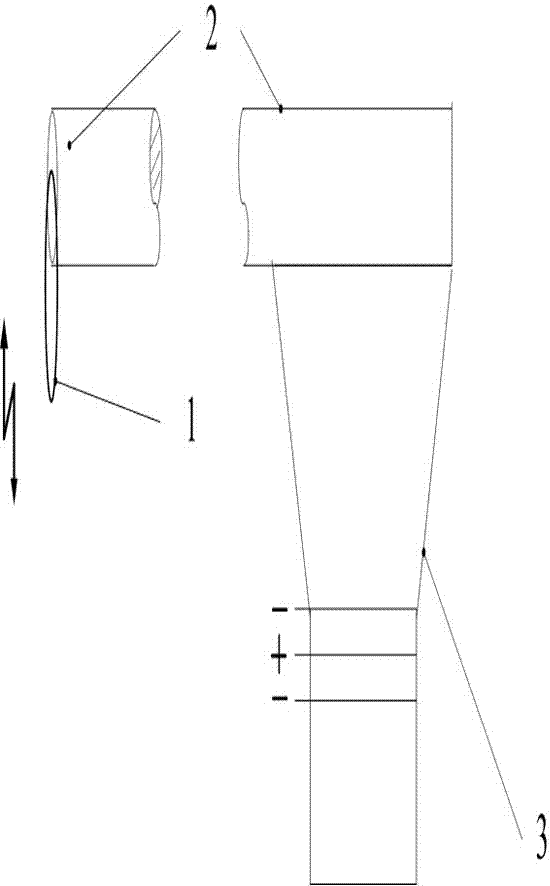

[0016] The micro-scale flexible ultrasonic tool 1 is a ring surrounded by glass fibers with a diameter of 10 microns. The diameter of the ring is 2 mm. The upper end of the micro-scale flexible ultrasonic tool 1 is pasted on the center of the left end of the vibration transmission rod 2. The rod 2 is made of stainless steel with a diameter of 1.4mm. The vibration transmission rod 2 is welded on the radiation surface of the ultrasonic transducer 3, and the ultrasonic transducer 3 can also be a piezoelectric sheet. The micro-nanoscale material A is a silver nanowire with a diameter of 300 nanometers and a length of 30 micrometers. Nanoscale material B is zinc oxide particles with a diameter of 100 nanometers. When the micro-scale flexible ultrasonic tool 1 is used as a driving part, when it is driven by an external sinusoidal alternating current signal, due to the inverse piezoelectric effect, the piezoelectric sheet is periodically deformed.

[0017] The specific experimental ...

Embodiment 2

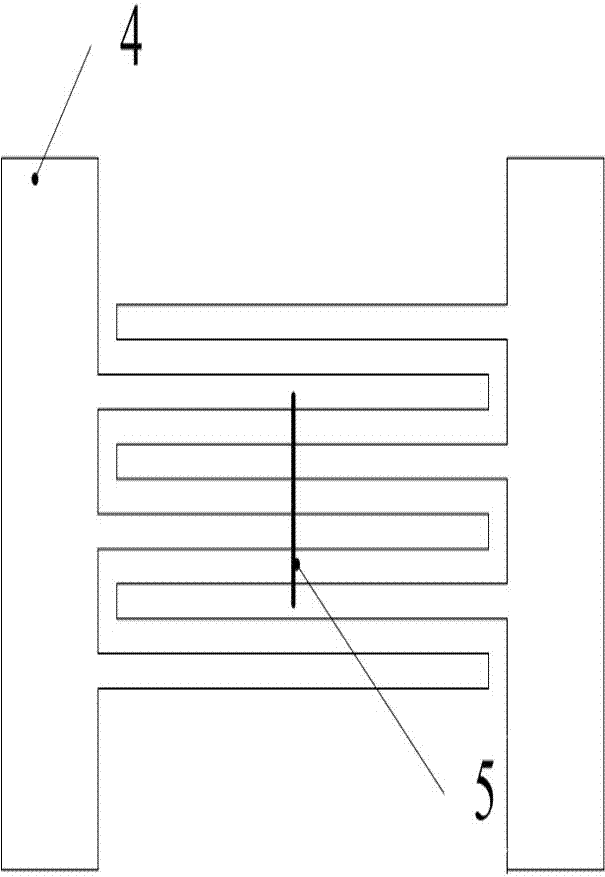

[0019] The micro-scale flexible ultrasonic tool 1 is a ring surrounded by carbon fibers with a diameter of 5 microns. The diameter of the ring is 1.5 mm. The upper end point of the micro-scale flexible ultrasonic tool 1 is pasted on the center of the left end of the vibration transmission rod 2. 2 is stainless steel with a diameter of 1.4 mm. The vibration transmission rod 2 is welded on the radiation surface of the ultrasonic transducer 3. The ultrasonic transducer 3 can also be a piezoelectric sheet. The distance between adjacent interdigital electrodes on the IDT electrode substrate is 5 Micron, the electrode width is 5 microns. The micro-nanoscale material A is a silver nanowire with a diameter of 300 nanometers and a length of 30 micrometers. Nanoscale material B is zinc oxide particles with a diameter of 100 nanometers. When the micro-scale flexible ultrasonic tool 1 is used as a driving part, when it is driven by an external sinusoidal alternating current signal, due t...

Embodiment 3

[0022] The micro-scale flexible ultrasonic tool 1 is a ring surrounded by copper fibers with a diameter of 40 microns. The diameter of the ring is 2 mm. The upper end point of the micro-scale flexible ultrasonic tool 1 is attached to the center of the left end of the vibration transmission rod 2. The rod 2 is made of stainless steel with a diameter of 1.4mm. The vibration transmission rod 2 is welded on the radiation surface of the ultrasonic transducer 3, and the ultrasonic transducer 3 can also be a piezoelectric sheet. The micro-nanoscale material A is a silver nanowire with a diameter of 300 nanometers and a length of 30 micrometers. Nanoscale material B is zinc oxide particles with a diameter of 100 nanometers. When the micro-scale flexible ultrasonic tool 1 is used as a driving part, when it is driven by an external sinusoidal alternating current signal, due to the inverse piezoelectric effect, the piezoelectric sheet is periodically deformed.

[0023] The specific expe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com