PVB (polyvinyl butyral) film with sound insulation performance and preparation method of PVB film

A sound insulation performance and film technology, which is applied in the field of PVB film and its preparation, can solve the problems of film mechanical properties decline, plasticizer precipitation, processing difficulties, etc., achieve significant economic and social benefits, uniform thickness, and improve sound insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

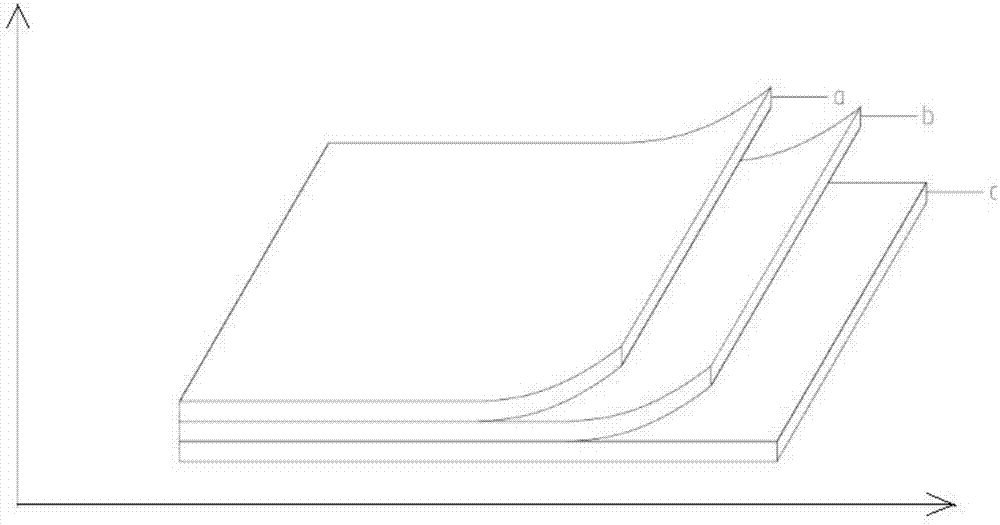

[0042] A kind of preparation method of above-mentioned three-layer type PVB film with sound insulation performance, comprises steps as follows:

[0043] The first step is to improve the preparation of PVB resin powder. The specific steps include:

[0044] (1) Condensation reaction: use water above 98°C and polyvinyl alcohol (PVA) in the reaction kettle to prepare a solution with a concentration of 8-10%, cool the solution to 5-10°C, and then add hydrochloric acid and normal Butyraldehyde is subjected to a condensation reaction, wherein hydrochloric acid and n-butyraldehyde respectively account for 1.0-6.0wt% and 3.0-10.0wt% of the total mass of the solution by mass percentage;

[0045]Among them, the polyvinyl alcohol (PVA) is divided into two types, one is prepared for the upper and lower outer layers of PVB film, and the viscosity of this polyvinyl alcohol (PVA) is 24-34cp / 20°C (test standard GB / T12010. 2-2010), the PVB obtained by the reaction is characterized by high melt...

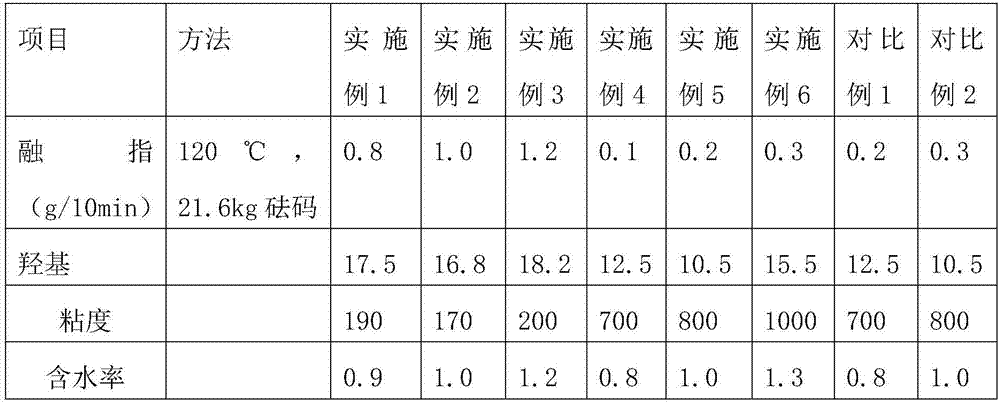

Embodiment 1-6

[0050] Examples 1-6 were prepared according to the above-mentioned specific preparation methods. For specific raw materials and proportions, see Table 1. No additives were added in the comparative examples, and they were also prepared according to the above-mentioned specific preparation methods.

[0051] (1) What embodiment 1-3 adopts is PVA raw material, and PVA viscosity control is 24-34cp / 20 ℃ (test standard GB / T12010.2-2010), and reaction obtains PVB characteristic is that melting index is higher, viscosity is low, mechanical Good mechanical properties to ensure the safety of laminated glass. Used to prepare the bottom film.

[0052] (2) Implementation 4-6 uses PVA raw materials, the viscosity of PVA is controlled at 30-90cp / 20°C (test standard GB / T12010.2-2010), and the reaction synthetic sound insulation resin PVB has a low melt index, which is characterized by processing leveling Well, casting is easy to form a uniform film of 0.05-0.45mm, which is used to prepare the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com