Coating method of anti-slide wear-proof coating layer of concrete PC beam and concrete PC beam

A technology of wear-resistant coating and coating method, which is applied in the field of coating of concrete PC beams and concrete PC beams with anti-slip and wear-resistant coatings, which can solve the problems of train safety hazards, reduced frictional resistance coefficient, and many capillary structures. Achieve good wear resistance and compression resistance, prevent coating hollowing or bubbles, and enhance coating adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

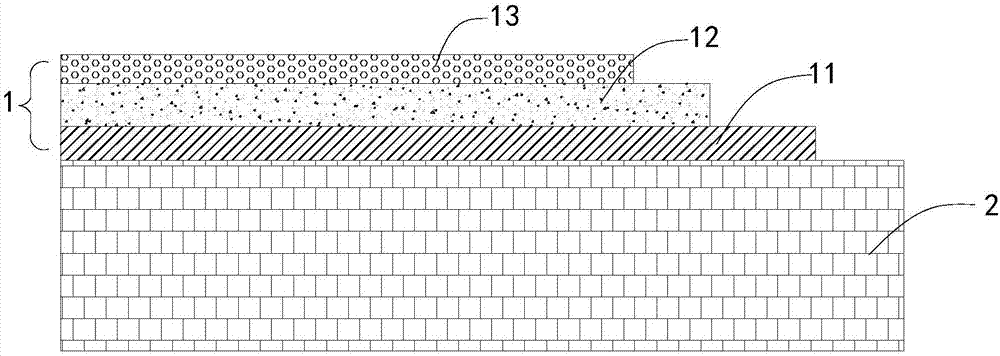

[0039] Such as figure 1 Shown, the coating method of concrete PC beam antiskid wear-resistant coating, described coating method comprises the following steps:

[0040] S1, pretreating the concrete PC beam 2, so that the surface to be painted of the concrete PC beam 2 is dry and clean, free of dirt and oil, and the surface roughness meets the preset requirements;

[0041] S2, coating the primer 11 on the surface to be painted of the concrete PC beam 2;

[0042] S3, after the primer 11 is dry, apply the anti-slip and wear-resistant paint film 12 on the primer 11, and wait until the anti-skid and wear-resistant paint film 12 is dry.

[0043]The environmental conditions for coating the anti-slip and wear-resistant coating 1 of the present embodiment are: the air temperature is between 5°C and 35°C, and construction in rain, fog, snow, wind and dust is prohibited; the air humidity is less than 80%; the concrete PC The temperature of the base surface of the beam should be more tha...

Embodiment 2

[0060] Such as figure 1 As shown, in the concrete PC beam of this embodiment, the concrete PC beam 2 is coated with an anti-slip and wear-resistant coating 1, and the anti-slip and wear-resistant coating 1 is coated on the concrete PC by the method described in Example 1. The surface of beam 2.

[0061]The thickness of the anti-slip and wear-resistant coating of the present embodiment is tested to the thickness of the paint film coating on the PC beam walking surface by GB / T1764-1979 "Method for Determination of Paint Film Thickness"; testing equipment: TT220 type magnetic thickness gauge; quality standard, Detection value: The total thickness of the coating should be greater than 3mm.

[0062] The adhesion performance of the anti-slip and wear-resistant coating of the present embodiment is tested by the cross-hatch method according to GB / T5210-2006 / ISO 4624:2002 "Paint and Varnish Cross-hatch Adhesion Test"; quality standard, test value: coating Adhesion level 0.

[0063] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com