Plant essential oil extraction device and method

A plant essential oil and extraction device technology, which is applied in the direction of essential oil/fragrance, fat production, etc., can solve the problems of ineffective recovery of essential oil, reduced yield of essential oil, and less application, so as to improve quality and extraction yield of essential oil, and increase yield efficiency and quality, and the effect of lowering the extraction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

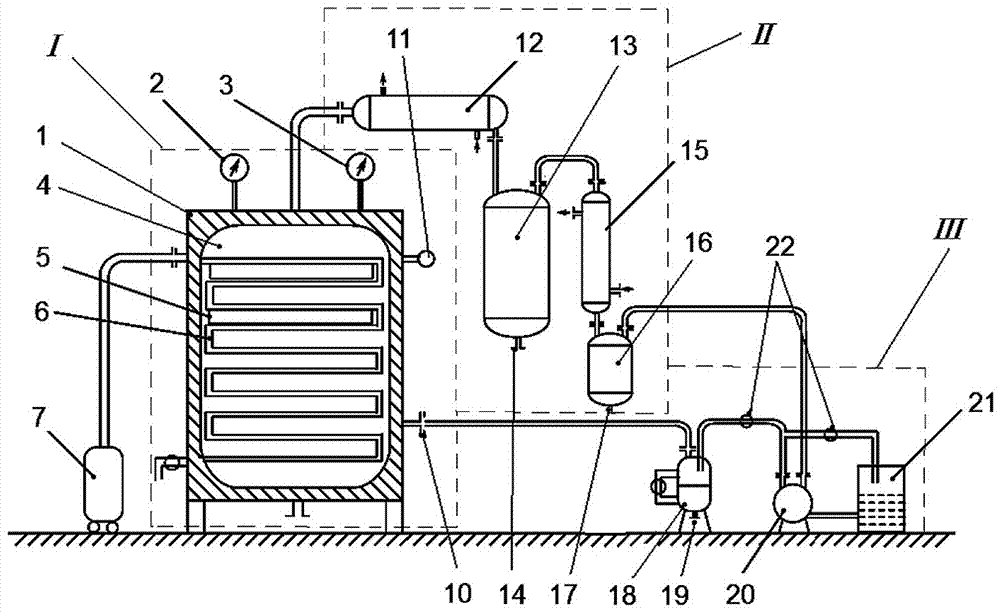

[0027] As shown in the figure, the plant essential oil extraction device of the present invention includes a vacuum cycle extraction system composed of indirect heating vacuum evaporation unit I, condensation unit II and vacuum unit III connected in sequence. in:

[0028]An extraction structure 1 is provided in the indirect heating vacuum evaporation unit I. The extraction structure 1 has a sealable cavity space 4 with a venting structure 11, and a layered steam heating pipe with an external heating steam source 7, or a heating structure 6 in the form of a PTC connected to an external power supply ( Shown in the figure is a steam heating pipeline), which is matched with a tray-type material carrying structure 5 with a through-hole or grid ventilation structure. Wherein, a digital or pointer temperature display structure 2 and a vacuum degree display structure 3 are respectively provided in the airtight cavity space 4 . The gas outlet provided in the sealable cavity space 4 i...

Embodiment 2

[0032] use figure 1 The plant essential oil extraction device shown extracts rose flower essential oil.

[0033] The basic process of vacuum circulation extraction is to place 50kg of rose flowers in a vacuum circulation extraction system composed of sequentially connected indirect heating vacuum evaporation unit I, condensation unit II and vacuum unit III capable of internal / external circulation conversion. In the tray-type material carrying structure 5 with grid through holes between the layered heating structures 6 in the indirect heating vacuum evaporation unit, the vacuum degree of the extraction system is formed by the external circulation of the water ring vacuum pump in the vacuum unit. After the vacuum environment of 0.075MPa, switch to heating to 40-50°C under the condition of maintaining the vacuum degree of the extraction system and isolating the gas in the extraction system from the external environment, and circulating in the extraction system for 4 hours. Durin...

Embodiment 3

[0035] use figure 1 The plant essential oil extracting device shown, according to the operation process and the mode of embodiment 2, respectively take 50kg of sweet-scented osmanthus flowers as raw materials to extract the corresponding sweet-scented osmanthus essential oil. The basic process is basically the same as the above extraction of rose essential oil. The difference is that the cyclic extraction vacuum degree of the extraction system is -0.09MPa, and the cyclic extraction is carried out under the heating condition of 35-45°C for 5 hours. The liquid after the collected gas-liquid separation was left to stand for 4 hours to carry out oil-water separation, and the yield of the obtained sweet-scented osmanthus essential oil product was 0.03%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com