Pretreatment method for reducing amygdalin in green plum vinegar

A kind of technology of amygdalin and green plum vinegar, which is applied in the field of beverage processing, can solve the problems of ineffective removal of amygdalin, short high-temperature heating process, and loss of beneficial ingredients, so as to retain fruit components and fragrance, low cost, and promote cyanide. The effect of chemical transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

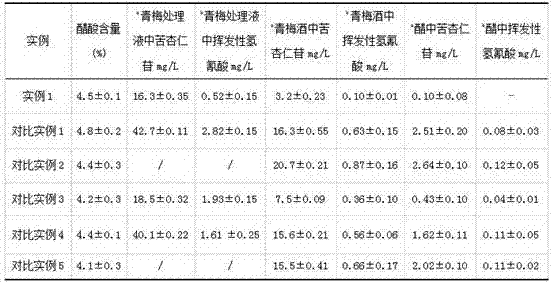

Examples

Embodiment 1

[0022] (1) Cultivate Bacillus subtilis overnight.

[0023] (2) Preparation of Bacillus subtilis lysate: Ultrasonic crushing conditions are as follows: the volume of the bacterial liquid cultivated overnight in step (1) is concentrated by 3 times and crushed; the ultrasonic crushing time of each 50mL bacterial liquid is 15s, the interval is 25s, and the total crushing time is 10 Minutes, the ultrasonic crushing strength is 60%.

[0024] (3) Greengage pretreatment: wash 10Kg greengage, remove the core, crush it with a grinder, add 30Kg water, 80g pectinase and 100g cellulase, 1L Bacillus subtilis lysate, 3Kg soybean meal, and place in a closed fermentation tank , kept at 25°C for 6 hours, stirred every 30 minutes, the enzyme activities of pectinase and cellulase were 10000U / g and 20000U / g respectively.

[0025] (4) Alcoholic fermentation: Add 400 g of sucrose and 200 g of active dry yeast to the greengage pretreatment liquid in the original fermenter in step (3); after aeration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com