A method for improving the activity of glutamic acid decarboxylase with d101 macroporous adsorption resin

A glutamic acid decarboxylase and adsorption resin technology, applied in the biological field, can solve the problems of high cost of γ-aminobutyric acid and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

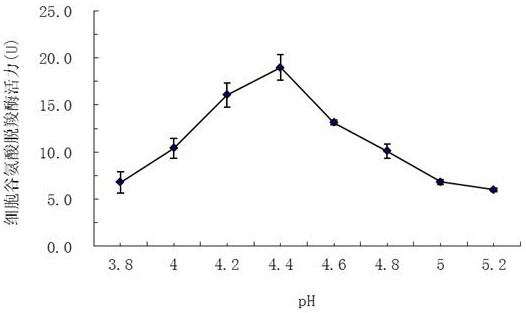

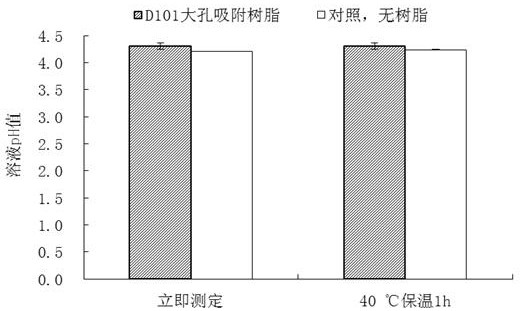

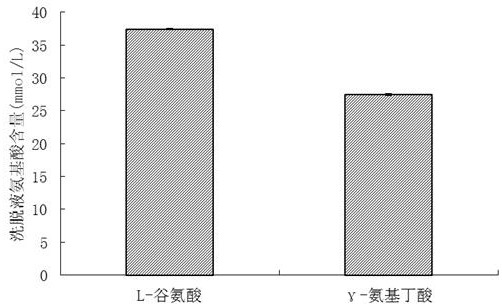

Method used

Image

Examples

Embodiment 1

[0064] A kind of method of improving glutamic acid decarboxylase activity with D101 macroporous adsorption resin of the present invention comprises the following steps:

[0065] ①. Dissolve L-glutamate monosodium (monosodium glutamate) in 0.2mol / L acetic acid-sodium acetate buffer solution, adjust the pH to 4.2-4.6, and prepare 0.2mol / L-0.3mol / L L-glutamic acid Monosodium solution, as substrate solution;

[0066] ②. Pretreat the D101 macroporous adsorption resin with 95% ethanol and distilled water according to the instructions of the resin, and then balance it with the substrate solution;

[0067] ③. The mass of D101 macroporous adsorption resin balanced according to step ②: the volume of substrate solution: the volume of Enterococcus faecium GDMCC60203 bacterial suspension is mixed in a ratio of 1:1:1, and the mixture is glutamic acid decarboxylase compound transformation reaction system;

[0068] ④. React the mixture in step ③ in 80r / min, 37℃~43℃ water bath shaker or stir a...

Embodiment 2

[0071] A kind of method of improving glutamic acid decarboxylase activity with D101 macroporous adsorption resin of the present invention comprises the following steps:

[0072] ①. Dissolve L-glutamic acid in 0.2 mol / L acetic acid-sodium acetate buffer solution, adjust the pH to 4.2-4.6, and prepare 0.2 mol / L-0.3 mol / L L-glutamic acid solution as a substrate solution;

[0073] ②. Pretreat the D101 macroporous adsorption resin with 95% ethanol and distilled water according to the instructions of the resin, and then balance it with the substrate solution;

[0074] ③. The mass of D101 macroporous adsorption resin balanced according to step ②: the volume of substrate solution: the volume of Enterococcus faecium GDMCC60203 bacterial suspension is mixed in a ratio of 1:1:1, and the mixture is glutamic acid decarboxylase compound transformation reaction system;

[0075] ④. React the mixture in step ③ in 80r / min, 37℃~43℃ water bath shaker or stir at 37℃~43℃ at low speed or stand for...

Embodiment 3

[0078] A kind of method utilizing D101 macroporous adsorption resin of the present invention to improve glutamic acid decarboxylase activity comprises the following steps:

[0079] ①. Dissolve L-glutamate monosodium (monosodium glutamate) in 0.2mol / L acetic acid-sodium acetate buffer solution, adjust the pH to 4.2-4.6, and prepare 0.2mol / L-0.3mol / L L-glutamic acid Monosodium solution, as substrate solution;

[0080] ②. Pretreat the D101 macroporous adsorption resin with 95% ethanol and distilled water according to the instructions of the resin, and then balance it with the substrate solution;

[0081] ③.Balanced D101 macroporous adsorption resin according to step ②Mass: Volume of substrate solution: Enterococcus faecium GDMCC60203 glutamic acid decarboxylase free enzyme solution volume is 1:1:1 Mix the three, the mixture is glutamic acid Acid decarboxylase complex conversion reaction system;

[0082] ④. React the mixture in step ③ in 80r / min, 37℃~43℃ water bath shaker or sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com