Method for improving activity of glutamate decarboxylase by virtue of 732 cation exchange resin

A glutamic acid decarboxylase and cation exchange technology, applied in the biological field, can solve the problem of high cost of γ-aminobutyric acid, and achieve the effects of easy separation and recovery, lower production costs, and no environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

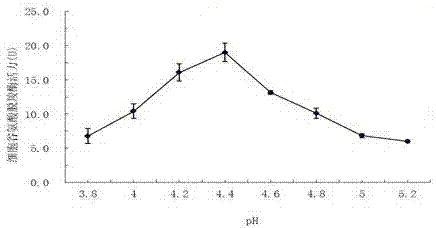

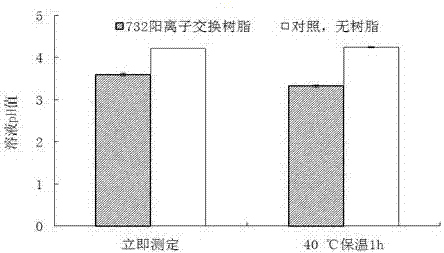

[0064] A method of utilizing 732 cation exchange resin to improve the activity of glutamic acid decarboxylase according to the present invention comprises the following steps:

[0065] ①. L - Monosodium glutamate (monosodium glutamate) was dissolved in 0.2 mol / L acetic acid-sodium acetate buffer, adjusted to pH 4.2 to 4.6, and prepared to 0.2 mol / L to 0.3 mol / L L - Monosodium glutamate solution as substrate solution;

[0066] ②. The 732 cation exchange resin was regenerated or pretreated with 1 mol / L NaOH and 1 mol / L HCl according to the resin instructions, and then fully equilibrated with pH 4.2~pH 4.6, 0.2 mol / L acetic acid-sodium acetate buffer, and then Equilibrate with substrate solution;

[0067] ③. Mix the three in the ratio of 732 cation exchange resin balanced in step ②: volume of substrate solution: volume of Enterococcus faecium GDMCC 60203 bacterial suspension is 1: 1: 1, the mixture is glutamate decarboxylase compound transformation reaction system;

[0068] ④...

Embodiment 2

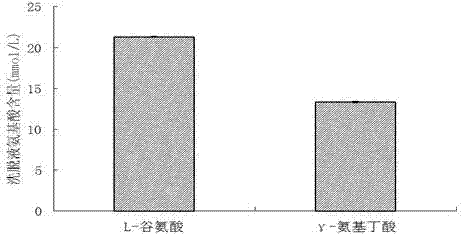

[0071] A method of utilizing 732 cation exchange resin to improve the activity of glutamic acid decarboxylase according to the present invention comprises the following steps:

[0072] ①. L - Glutamic acid was dissolved in 0.2 mol / L acetic acid-sodium acetate buffer, adjusted to pH 4.2-4.6, and prepared to 0.2 mol / L-0.3 mol / L L - Monosodium glutamate solution as substrate solution;

[0073] ②. The 732 cation exchange resin was regenerated or pretreated with 1 mol / L NaOH and 1 mol / L HCl according to the resin instructions, and then fully equilibrated with pH 4.2~pH 4.6, 0.2 mol / L acetic acid-sodium acetate buffer, and then Equilibrate with substrate solution;

[0074] ③. Mix the three in the ratio of 732 cation exchange resin balanced in step ②: volume of substrate solution: volume of Enterococcus faecium GDMCC 60203 bacterial suspension is 1: 1: 1, the mixture is glutamate decarboxylase compound transformation reaction system;

[0075] ④. React the mixture in step ③ at 80 ...

Embodiment 3

[0078] A method of utilizing 732 cation exchange resin to improve the activity of glutamic acid decarboxylase according to the present invention comprises the following steps:

[0079] ①. L - Monosodium glutamate (monosodium glutamate) was dissolved in 0.2 mol / L acetic acid-sodium acetate buffer, adjusted to pH 4.2 to 4.6, and prepared to 0.2 mol / L to 0.3 mol / L L - Monosodium glutamate solution as substrate solution;

[0080] ②. The 732 cation exchange resin was regenerated or pretreated with 1 mol / L NaOH and 1 mol / L HCl according to the resin instructions, and then fully equilibrated with pH 4.2~pH 4.6, 0.2 mol / L acetic acid-sodium acetate buffer, and then Equilibrate with substrate solution;

[0081] ③. Mix the three 732 cation-exchange resin balance in step ②: volume of substrate solution: volume of Enterococcus faecium GDMCC 60203 glutamate decarboxylase free enzyme solution in a ratio of 1:1:1, the mixture is glutamate Acid decarboxylase complex conversion reaction sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com