A kind of corrosion-resistant bainite steel, steel rail and preparation method

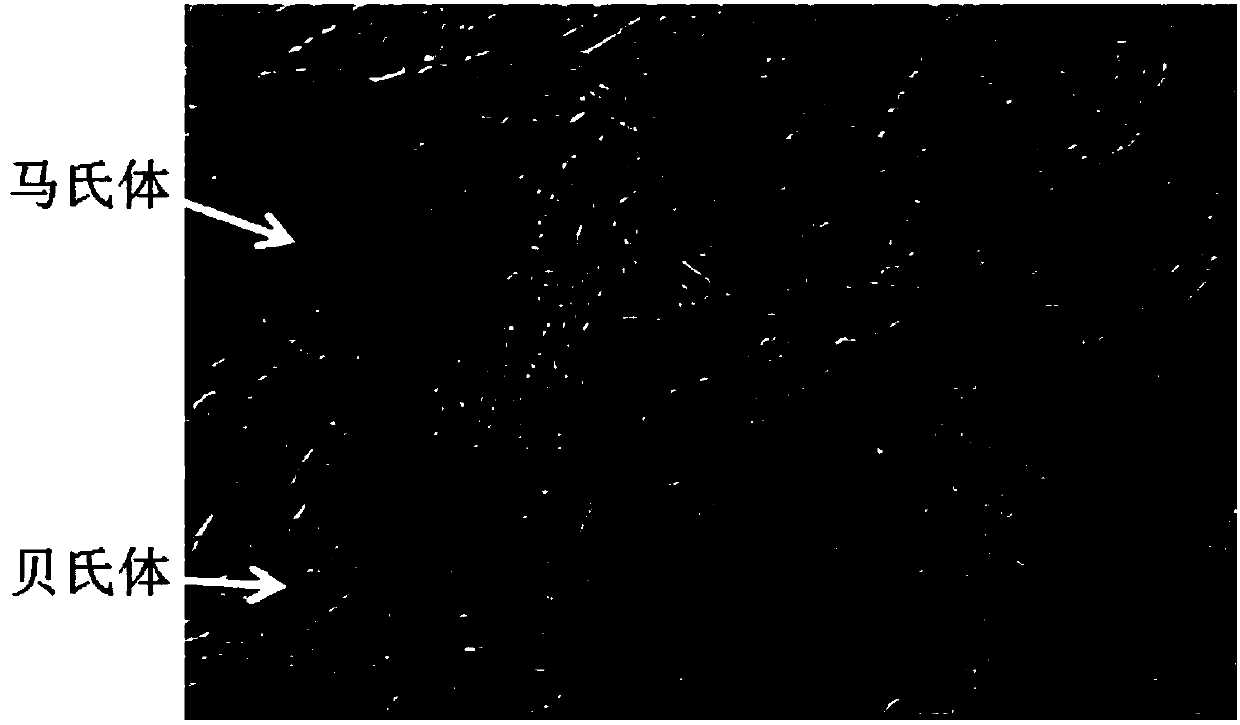

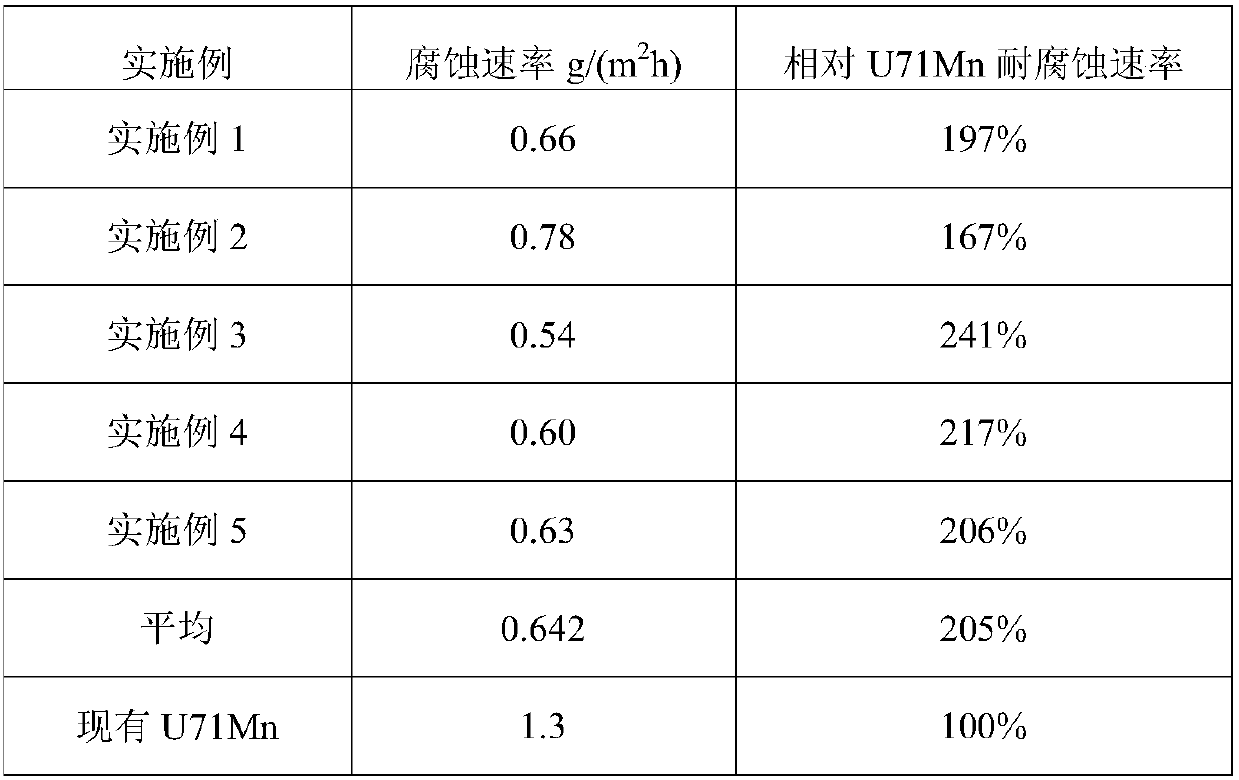

A bainitic steel and bainite technology, applied in the field of rail and preparation, low-carbon 1300MPa grade high-strength corrosion-resistant bainitic steel, to improve corrosion resistance, increase toughness, improve plasticity and atmospheric corrosion resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

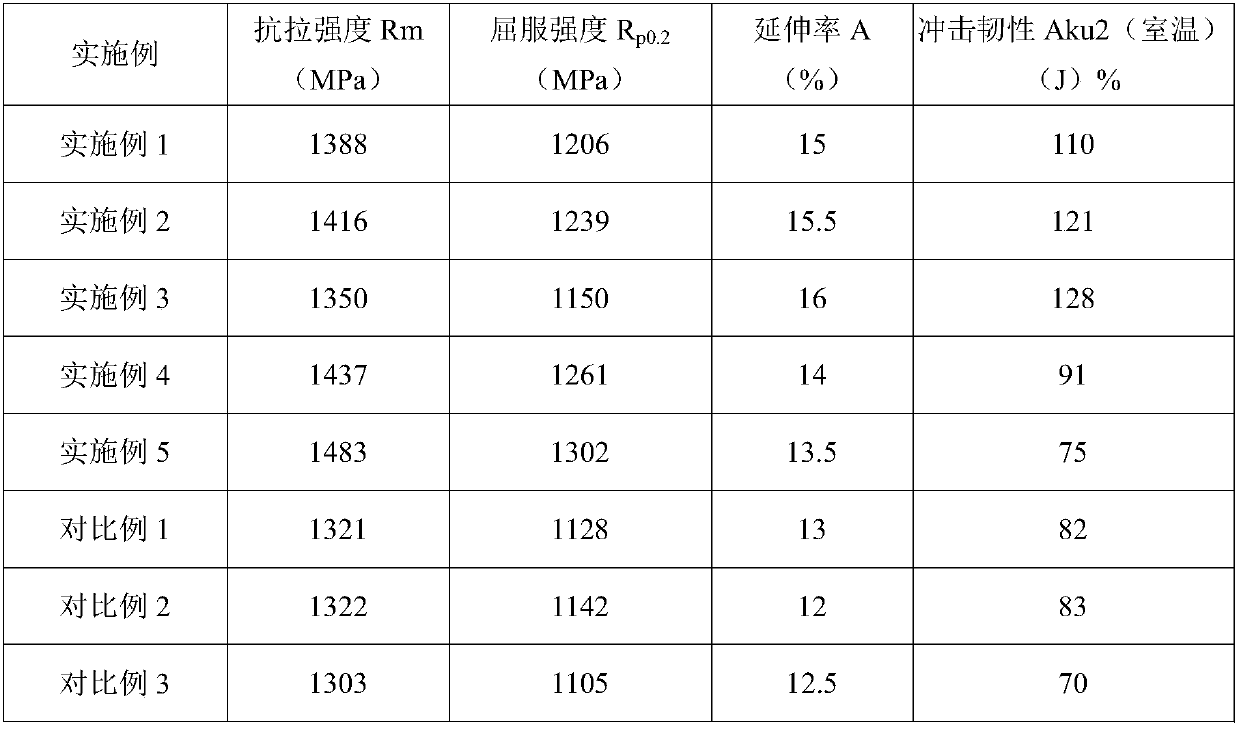

Examples

Embodiment 1

[0049] The corrosion-resistant bainitic steel rail is made of corrosion-resistant bainitic steel, wherein the content of each component of the corrosion-resistant bainitic steel is shown in Table 1. In the CCT curve of the steel, martensitic transformation occurs The critical cooling rate is above 10°C / s. The preparation method of this steel rail is as follows:

[0050] 1) According to the formula of this embodiment in Table 1, adopt conventional steelmaking process, carry out smelting and refining by converter or electric furnace, adopt the mode of continuous casting to carry out casting again, obtain slab;

[0051] 2) Heating the billet to 1250°C, keeping it warm for 2 hours, and then going through billet opening, rough rolling, and finish rolling to obtain the rail prototype, wherein the final rolling temperature of the finish rolling is 900°C;

[0052] 3) The rail prototype is continuously cooled to room temperature by means of strong fog cooling at an average cooling rat...

Embodiment 2

[0056] The corrosion-resistant bainitic steel rail is made of corrosion-resistant bainitic steel, wherein the content of each component of the corrosion-resistant bainitic steel is shown in Table 1. In the CCT curve of the steel, martensitic transformation occurs The critical cooling rate is above 10°C / s. The preparation method of this steel rail is as follows:

[0057] 1) According to the formula of this embodiment in Table 1, adopt conventional steelmaking process, carry out smelting and refining by converter or electric furnace, adopt the mode of continuous casting to carry out casting again, obtain slab;

[0058] 2) Heating the billet to 1200°C, keeping it warm for 2 hours, and then going through billet opening, rough rolling, and finish rolling to obtain a rail prototype, wherein the final rolling temperature of finish rolling is 950°C;

[0059] 3) The rail prototype is cooled continuously to room temperature with an average cooling rate of 5°C / s by means of strong air c...

Embodiment 3

[0062] The corrosion-resistant bainitic steel rail is made of corrosion-resistant bainitic steel, wherein the content of each component of the corrosion-resistant bainitic steel is shown in Table 1. In the CCT curve of the steel, martensitic transformation occurs The critical cooling rate is above 10°C / s. The preparation method of this steel rail is as follows:

[0063] 1) According to the formula of this embodiment in Table 1, adopt conventional steelmaking process, carry out smelting and refining by converter or electric furnace, adopt the mode of continuous casting to carry out casting again, obtain slab;

[0064] 2) Heating the billet to 1200°C, keeping it warm for 2.5 hours, and then going through blanking, rough rolling, and finish rolling to obtain a rail prototype, wherein the final rolling temperature of the finish rolling is 950°C;

[0065] 3) The rail prototype is cooled continuously to room temperature with an average cooling rate of 4°C / s by means of fog cooling;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com