Interface-enhancement emulsion type sizing agent used for carbon fibers, and preparation method thereof

An interface enhancement, emulsion type technology, applied in the direction of carbon fiber, fiber type, fiber treatment, etc., can solve problems such as poor temperature resistance and poor compatibility with epoxy resin systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The present invention also provides a method for preparing an interface-reinforced emulsion-type sizing agent for carbon fibers, the method comprising:

[0034] Step 1: dissolving the polyarylether resin in an organic solvent, stirring it to make it evenly mixed, and obtaining the main slurry; the stirring time is preferably 10 minutes to 30 minutes;

[0035] Step 2: Add emulsifier to the main slurry in Step 1, add coupling agent to deionized water, stir and mix evenly to obtain modified deionized water; the stirring time is preferably 5 minutes to 10 minutes;

[0036] Step 3: Select a high-speed shear emulsifier, preferably at 6000rpm-20000rpm, drop the modified deionized water obtained in step 2 into the main slurry in step 1, and continue stirring at a temperature of 30°C-60°C to disperse the system Uniform, that is, to obtain an interface-reinforced emulsion-type sizing agent for carbon fibers; the dropping rate is preferably 0.01ml / s-1ml / s, and the stirring time is...

Embodiment 1

[0039] The polyaryletherketone resin PEK-CH (the number average molecular weight is 1.0×10 4g / mol) was dissolved in chloroform and stirred for 15 minutes to obtain the main slurry, then sodium dodecylsulfonate was added and stirred for 5 minutes to dissolve it.

[0040] Add KH-550 into deionized water and stir for 5 minutes to make it evenly mixed to obtain modified deionized water;

[0041] Select a high-speed shear emulsifier, slowly add modified deionized water to the main slurry at 10000rpm, the dropping speed is 0.02ml / s, after the phase is reversed, the stirring speed is increased to 15000rpm, and the dropping speed is 1ml / s, and after the completion, the Continue to stir for 60 minutes to obtain an emulsion type sizing agent.

[0042] PEK-CH and CCl in the main slurry 3 The mass ratio of sodium dodecylbenzene sulfonate and KH-550 are 10% and 6% of the main slurry respectively, and the mass ratio of deionized water to the main slurry is 80:20.

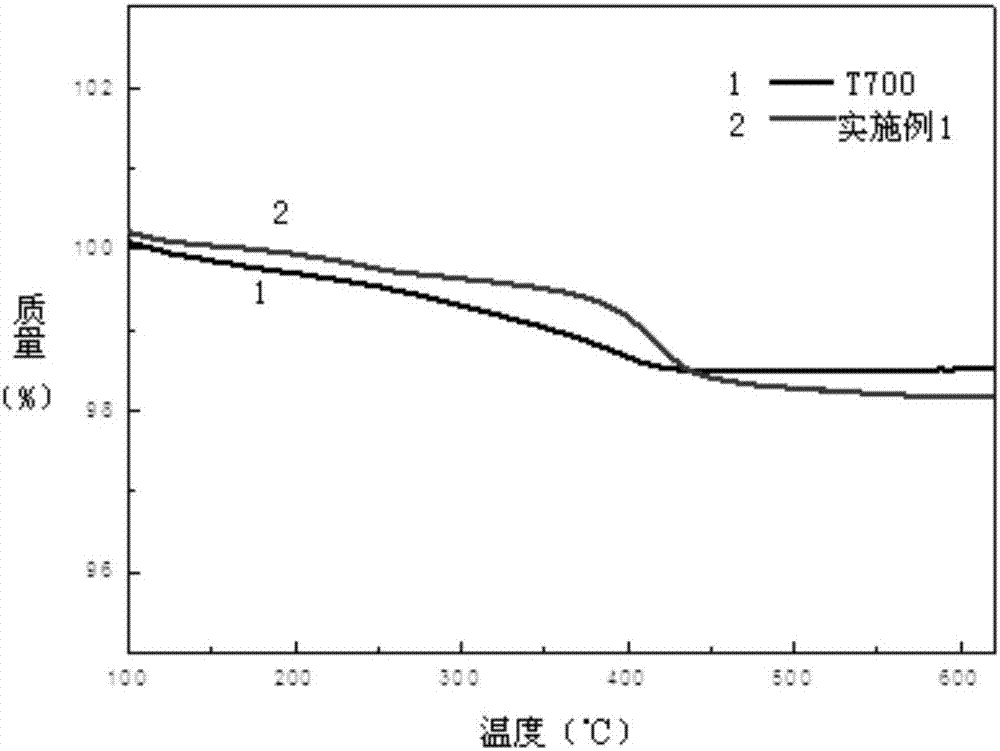

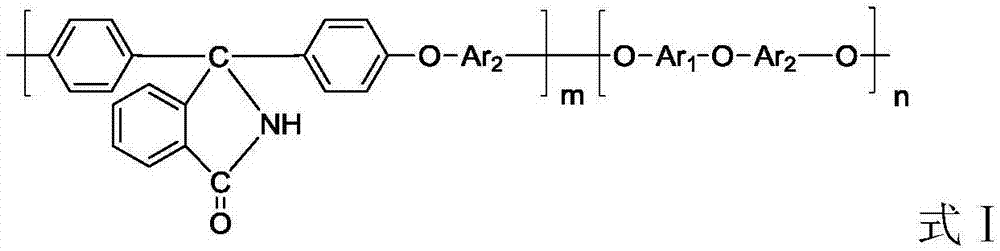

[0043] The structural ...

Embodiment 2

[0047] Polyaryletherketone resin PPLK (the number average molecular weight is 8.0×10 3 g / mol) was dissolved in N,N-dimethylacetamide and stirred for 15 minutes to obtain the main slurry, then EL-40 was added and stirred for 5 minutes to dissolve it.

[0048] Add KH-560 into deionized water and stir for 5 minutes to make it evenly mixed to obtain modified deionized water;

[0049] Select a high-speed shear emulsifier, slowly add the modified deionized water to the main slurry at 7000rpm, the dropping speed is 0.03ml / s, after the phase is reversed, the stirring speed is increased to 15000rpm, and the dropping speed is 1ml / s, and after the completion, under 10000rpm Continue to stir for 60 minutes to obtain an emulsion type sizing agent.

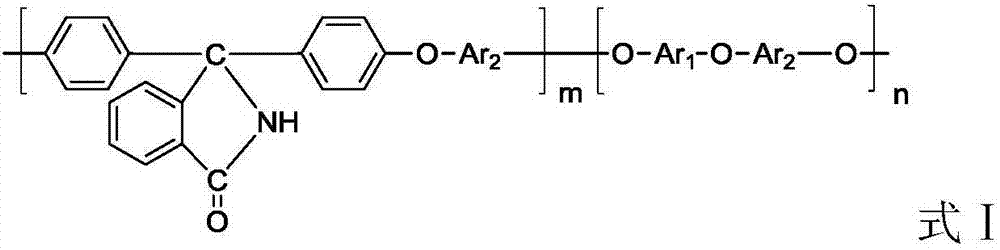

[0050] The mass ratio of PPLK and DMAC in the main slurry is 20:80, EL-40 and KH-560 are 8% and 4% of the main slurry mass respectively. The mass ratio of deionized water to main slurry is 70:30. The structural formula of the PPLK is as foll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com