Method of simply, easily and efficiently lowering content of magnesium in salt lake brine

A salt lake brine, appropriate technology, applied in the direction of magnesium hydroxide, lithium carbonate;/acid carbonate, etc., can solve the problems of easily destroying the ecological environment of the plateau salt lake area, high production costs, and increased transportation burden. , to achieve the effects of environmental friendliness, high magnesium removal efficiency, and reduced transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] A method for reducing magnesium content in salt lake brine, comprising the steps of:

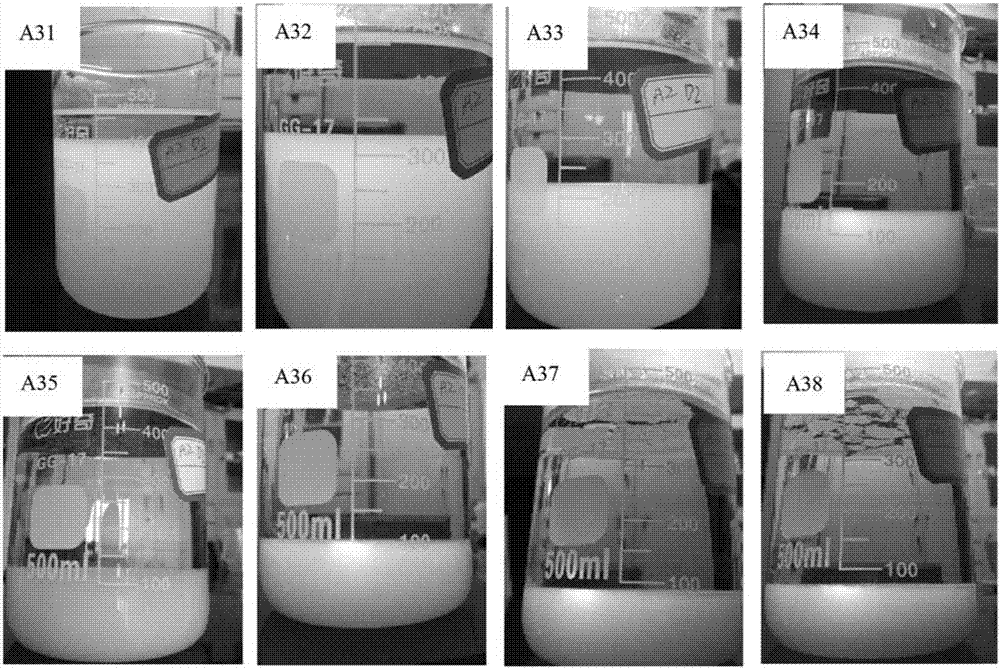

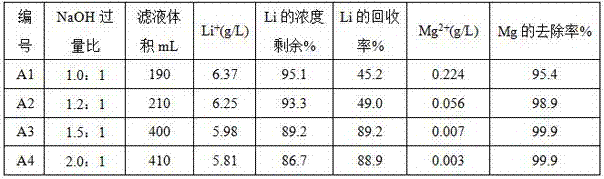

[0030] 1) Add excess water-soluble hydroxide to the brine of the salt lake, and the molar amount of the introduced hydroxide is completely precipitated Mg 2+ At least 1.5 times the theoretical dosage, stir well;

[0031] 2) Solid-liquid separation is carried out after static precipitation, and the filtrate is brine with low magnesium content.

[0032] In order to reduce the safety risk that excess hydroxide radicals bring preferably, the molar weight of the hydroxide radicals that introduces is complete precipitation Mg 2+ 1.5 to 2 times the theoretical dosage. This can ensure that the generated Mg(OH) 2 Rapid settling is possible, and remaining unreacted hydroxides are easier to remove.

[0033] As a further improvement of the above method, add an appropriate amount of salt lake brine in the filtrate, so that the molar weight of unreacted hydroxide in the filtrate is completely p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com