Parallel light micro-spot optical key dimension analysis device and detection method

A technology of key dimensions and detection methods, applied in the field of optical engineering, can solve the problems of RCWA calculation efficiency and other problems, and achieve the effect of overcoming the long time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] In order to more intuitively reflect the characteristics of the detection method of the optical critical dimension test / analysis system of the present invention, the embodiment selects the simulation efficiency of complex two-dimensional periodic structures to illustrate the difference between the RCWA / SAM detection method and the traditional RCWA detection and analysis tool .

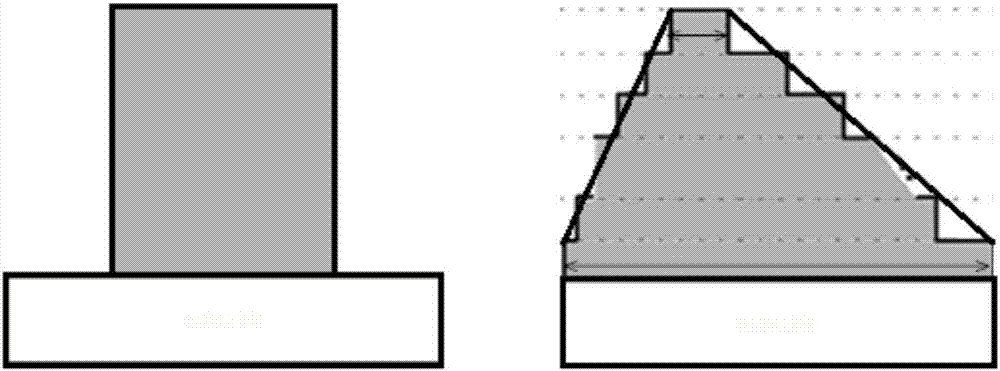

[0062] The surface structure of the sample is as Figure 5 As shown, the simplified shallow trench isolation (STI) 3D structure (left picture) and the simplified physical model (right picture) have a period of 402.9nm and 122.8nm in the x and y directions. The structure is a core-shaped elliptical array with non-vertical side walls. The major axis of the upper base in the x direction is 176.2 nm, the minor axis in the y direction is 30 nm, the major axis of the lower base in the x direction is 220 nm, and the minor axis in the y direction is 65 nm. The materials of the grating layer are all Si,...

Embodiment 2

[0066] The detection of the sample and the zero-order diffraction curve of the sample is the same as in Embodiment 1, wherein the detection lens 3 is connected to the spectrometer 4 through an optical fiber.

[0067] Curve simulation and comparison methods are different, specifically, Figure 5 The structure shown is a two-dimensional periodic structure, which is divided into 500 steps and approximate thin layers for simulation. The single simulation time for the test / analysis of critical dimensions is relatively long. Therefore, a mathematical and physical model database based on the structural parameters of the critical dimensions of the sample is established first. Example built in 10 4 Quantitative mathematical physical model, and calculate the simulated zero-order diffraction curve database of the sample mathematical physical model. The simulated zero-order diffraction curve database is compared with the measured zero-order diffraction curve of the sample by traversal me...

Embodiment 3

[0069] The device and detection method are the same as in Example 1, and the parameter curve of concern is replaced by an elliptical polarization parameter curve from the zero-order diffraction curve, and 100 step-approximate thin layers are divided for simulation. The analysis results are basically the same as in Example 1, and the time spent is reduced by 50%. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com