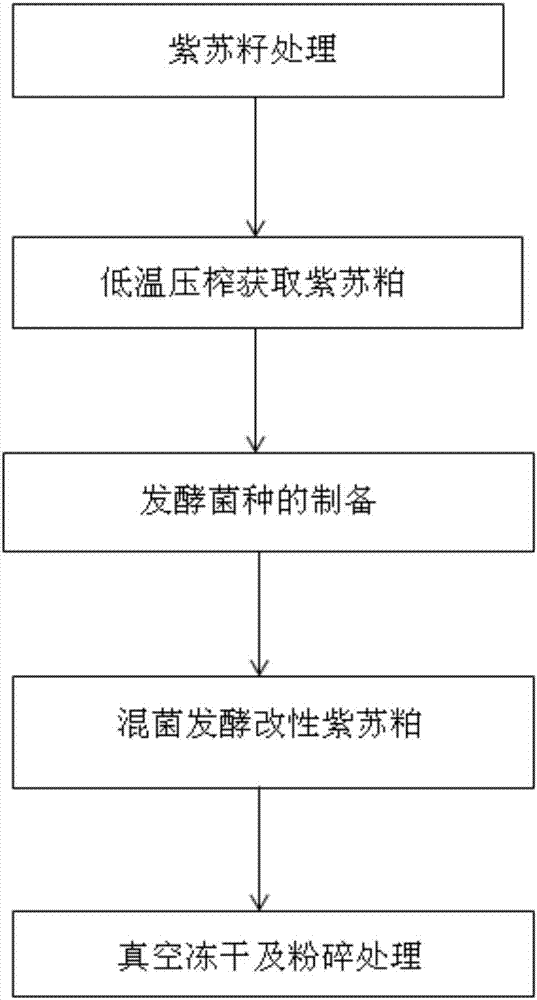

Method for preparing modified powdery purple perilla meal by fermentation of mixed bacteria

A technology of fermentation of perilla meal powder and mixed bacteria, which is applied in the field of food processing, to achieve the effect of processing suitability and nutritional value, and solving the effect of overly strong perilla aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] Step 3, preparation of fermentation strain

[0033] Inoculate Kluyveromyces marxense strains with a ratio of 1% in lactic acid bacteria culture medium MRS, and culture them in shake flasks at a temperature of 30°C for 18 hours to obtain the first-generation strain of Kluyveromyces marxenses;

[0034] Take the first-generation bacterial liquid of Kluyveromyces marxii with a ratio of 1% and place them in respective (specifically, several culture media and the names of the culture media) medium, and culture them in shake flasks at a temperature of 30°C 18h, obtain the second-generation bacterial liquid of Kluyveromyces marx;

[0035] Take the second-generation bacteria liquid of Kluyveromyces marxe and place it in a sterilized centrifuge tube. Centrifuge at 10,000 rpm for 10 minutes. Take the precipitated sludge after centrifugation, add sterile water and mix evenly. , centrifuged for 10min, took the centrifuged sludge, added sterile water and mixed evenly for later use; ...

Embodiment 1

[0046] The perilla seeds obtained in the above step 1 were extracted for low-temperature oil extraction at a temperature of 42° C. and an oil extraction pressure of 6 MPa to obtain perilla meal. Inoculate Bacillus coagulans in liquid medium A according to the proportion of 1%, and culture it in shake flask for 48 hours, the temperature is 37°C, this is the first-generation bacterial liquid; take 1% of the first-generation bacterial liquid in the respective medium, the culture conditions are the same as above, this is Second-generation bacterial liquid: put the second-generation Bacillus coagulans suspension into a sterilized centrifuge tube, centrifuge at 10,000rpm for 10min, take the centrifuged precipitate, add sterile water to the bacterial sludge and mix, and then centrifuge at 10,000rpm for 10min to obtain The fungus slime is mixed with sterile water and used for later use. Inoculate Bacillus natto in LB medium according to the ratio of 1%, culture at 36°C for 18 hours, t...

Embodiment 2

[0049] The perilla seeds obtained in the above step 1 were extracted for low-temperature oil extraction at a temperature of 48° C. and an oil extraction pressure of 5 MPa to obtain perilla meal. Inoculate Bacillus coagulans in liquid medium A according to the proportion of 1%, and culture it in shake flask for 48 hours, the temperature is 37°C, this is the first-generation bacterial liquid; take 1% of the first-generation bacterial liquid in the respective medium, the culture conditions are the same as above, this is Second-generation bacterial liquid: put the second-generation Bacillus coagulans suspension into a sterilized centrifuge tube, centrifuge at 10,000rpm for 10min, take the centrifuged precipitate, add sterile water to the bacterial sludge and mix, and then centrifuge at 10,000rpm for 10min to obtain The fungus slime is mixed with sterile water and used for later use. Inoculate Bacillus natto in LB medium according to the ratio of 1%, culture at 36°C for 18 hours, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com