Preparation method of collagen stanch fiber

A technology of hemostatic fiber and collagen, which is applied in medical science, surgery, surgical adhesives, etc., can solve the problems of long hemostasis time, low adhesion of hemostatic materials and wound surface, poor hemostatic effect, etc. Immunogenicity, Ease of Handling Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

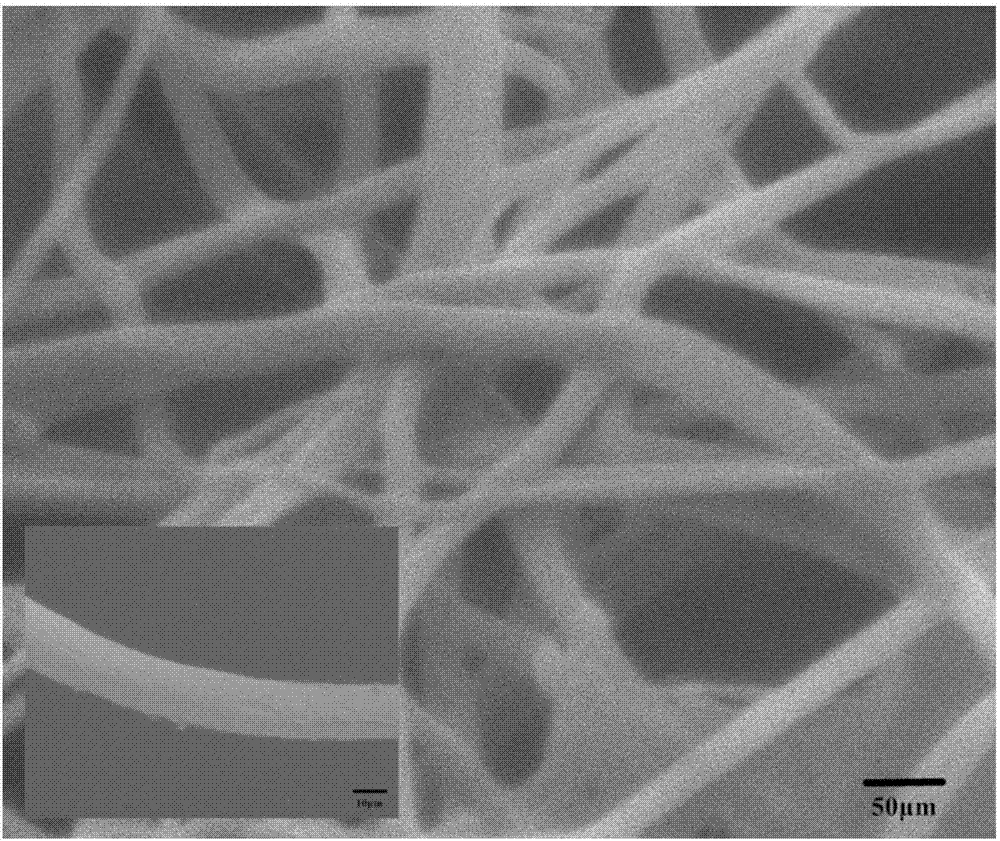

Image

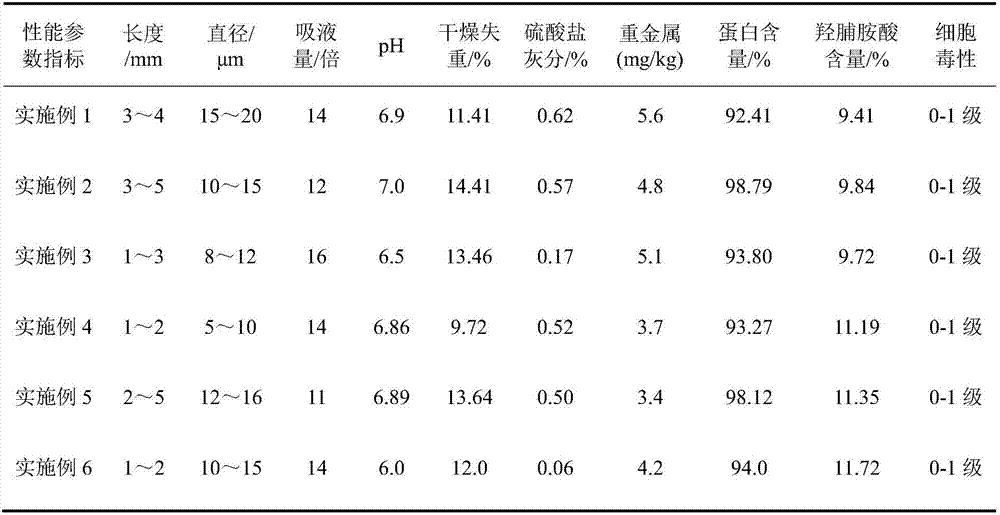

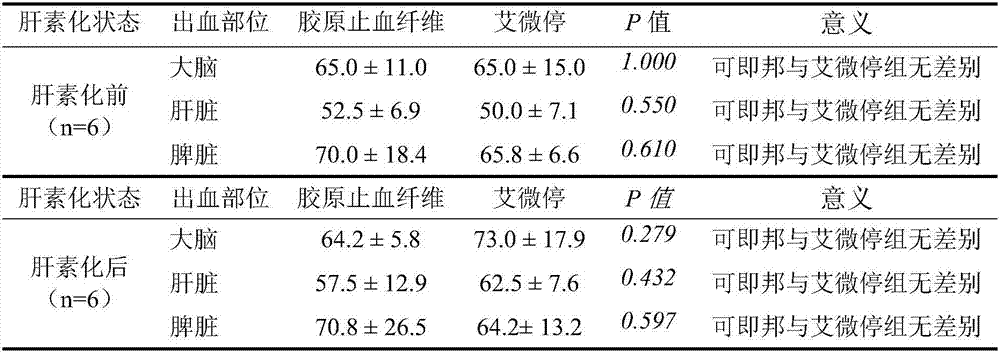

Examples

Embodiment 1

[0038] A preparation method of collagen hemostatic fiber is as follows:

[0039] S1: Take the back of the whole calfskin, use a shaving machine to remove the hair on the back of the calfskin, then use a blade to scrape off the fat layer and fluff layer on the cowhide, cut it into small pieces of about 1 to 2 cm, and place it in- Freeze at 50°C, then cut the frozen cowhide into slices with a thickness of about 0.2mm and a size of 1cm with a slicer;

[0040] S2: Degreasing treatment: Soak the skin slices in 2% sodium chloride solution, place on a magnetic stirrer and stir slowly for 24 hours, replace the soaking solution after 5-7 hours; then soak the skin slices in 1% sodium carbonate solution, Place it on a magnetic stirrer and stir slowly for 24 hours, and replace the soaking solution after 5-7 hours; finally transfer the skin slices to a lipolysis solution with 1% weight of the skin slices, place it on a magnetic stirrer and stir slowly for 24 hours, and the reaction pH is 9...

Embodiment 2

[0047] A preparation method of collagen hemostatic fiber is as follows:

[0048] S1: Take the back of the whole calfskin, use a shaving machine to remove the hair on the back of the calfskin, then use a blade to scrape off the fat layer and fluff layer on the cowhide, cut it into small pieces of about 1 to 2 cm, and place it in- Freeze at 50°C, and then cut the frozen cowhide into slices with a thickness of about 0.3mm and a size of 0.5cm with a slicer;

[0049] S2: Degreasing treatment: Soak the skin slices in 5% sodium chloride solution, place on a magnetic stirrer and stir slowly for 24 hours, replace the soaking solution after 5-7 hours; then soak the skin slices in 2% sodium carbonate solution, Put it on a magnetic stirrer and stir slowly for 24 hours, and replace the soaking solution after 5-7 hours; finally transfer the skin slices to a lipolysis solution with 2% weight of the skin slices, place it on a magnetic stirrer and stir slowly for 24 hours, and the reaction pH ...

Embodiment 3

[0055] A preparation method of collagen hemostatic fiber is as follows:

[0056] S1: Take the back of the whole calfskin, use a shaving machine to remove the long hair on the back of the calfskin, then use a blade to scrape off the fat layer on the calfskin, and then use Na 2 SO 4 :Na 2 S:CaCl 2 = 1:50:20 hair removal agent for hair removal for 15 minutes, after cleaning, cut into small pieces of about 1-2cm, freeze at -50°C, and then cut the frozen cowhide pieces with a slicer to a thickness of about 0.4mm and a size of 2cm the skin;

[0057] S2: Degreasing treatment: Soak the skin slices in 8% sodium chloride solution, place on a magnetic stirrer and stir slowly for 24 hours, replace the soaking solution after 5-7 hours; then soak the skin slices in 3% sodium carbonate solution, Put it on a magnetic stirrer and stir slowly for 24 hours, and replace the soaking solution after 5-7 hours; finally transfer the skin slices to a lipolysis solution with 3% weight of the skin sl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com