Method for repairing heavy metal soil by using magnesium silicate-hydrothermal carbon composite material

A composite material, magnesium silicate technology, applied in the field of repairing heavy metal soil with magnesium silicate-hydrothermal carbon composite material, can solve the problems of high cost, loss of nutrient elements, large dosage, etc., to prevent environmental migration and diffusion, reduce The effect of toxicity degree and excellent adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

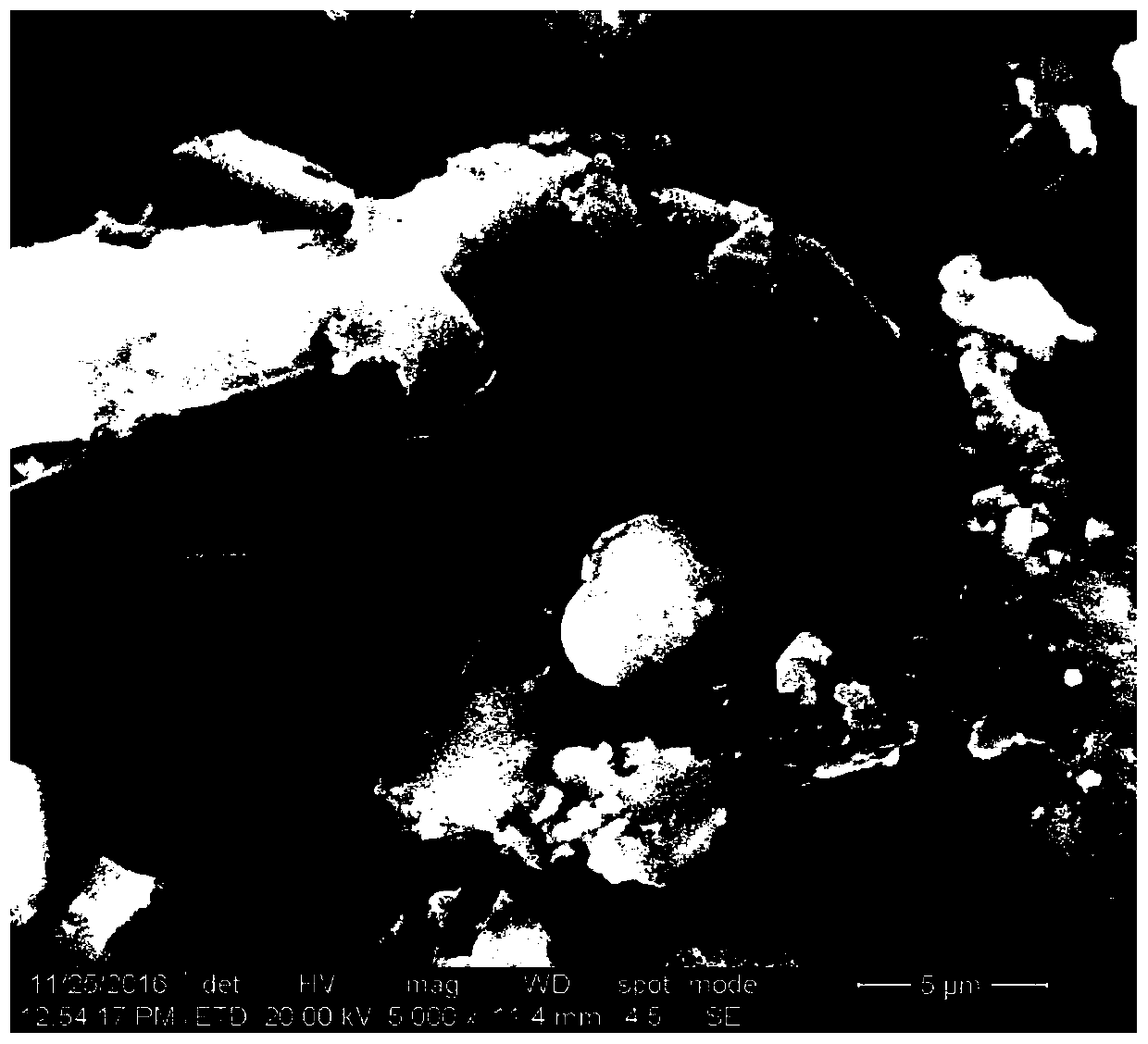

Image

Examples

Embodiment 1

[0045] A method of utilizing magnesium silicate-hydrothermal carbon composite material of the present invention to restore cadmium-contaminated soil comprises the following steps:

[0046] (1) Preparation of cadmium-contaminated soil: The test soil was collected from Yuelu Mountain in Hunan Province. The cadmium-contaminated soil was prepared by artificially adding cadmium solution. The cadmium-contaminated soil was incubated at a constant temperature of 25°C for two months to stabilize the form of cadmium. The total cadmium content in the soil was measured to be 8.4mg / kg by the graphite furnace digestion method. Soil remediation experiments were then carried out.

[0047] (2) Remediation of cadmium-contaminated soil: prepare four groups of cadmium-contaminated soils after the same weight steps (1) stabilization, wherein, in the first group, magnesium silicate-hydrothermal carbon composite materials with 1% of the weight of cadmium-contaminated soils are added, uniformly Mix;...

Embodiment 2

[0052] A method of utilizing the magnesium silicate-hydrothermal carbon composite material of the present invention to restore composite heavy metal polluted soil comprises the following steps:

[0053] (1) Collection of complex heavy metal-contaminated soil: The complex heavy metal-contaminated soil was collected from a lead-zinc mine polluted area in Chenzhou, Hunan. It was determined that the lead content was 155 mg / kg; the zinc content was 531.5 mg / kg; and the copper content was 113 mg / kg. It is much higher than the national standard value of soil, and the content of lead, zinc and copper in the surface layer of the soil in this area is more than twice the national soil environmental quality standard.

[0054] (2) Composite heavy metal contaminated soil remediation: prepare four groups of composite heavy metal contaminated soil of the same weight step (1), wherein, in the first group, add magnesium silicate-hydrothermal carbon composite material of 1% of composite heavy met...

Embodiment 3

[0058] Example 3: Research on physical and chemical properties of soil remediation by magnesium silicate-hydrothermal carbon composite materials

[0059] Prepare three groups of cadmium-contaminated soil after stabilization of embodiment 1 step (1) of the same weight, wherein, in the first group, add magnesium silicate-hydrothermal carbon composite material of 1% of cadmium-contaminated soil weight, and mix uniformly; Add magnesium silicate-hydrothermal carbon composite material with 3% weight of cadmium-contaminated soil to the group, and mix uniformly; add magnesium silicate-hydrothermal carbon composite material with 5% weight of cadmium-contaminated soil to the third group, and mix uniformly. The three groups of cadmium-contaminated soils were replenished with deionized water, so that the water retention of cadmium-contaminated soils was maintained at about 60% of the maximum field water capacity. After being stable for 30 days, water was used as solvent to extract the con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com