Preparation method and application of metal organic framework material

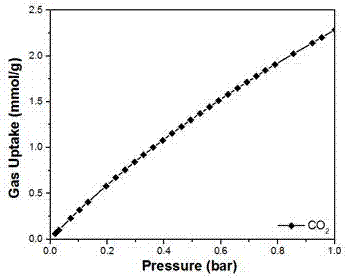

A metal-organic framework and organic phase technology, applied in separation methods, chemical instruments and methods, and other chemical processes, can solve the problem of low adsorption performance, achieve high adsorption rate, good chemical stability and thermal stability, and process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: A kind of preparation method of metal organic framework material, concrete steps are:

[0024] (1) At a temperature of 40°C, dissolve zirconium tetrachloride, hafnium tetrachloride, and 2-aminoterephthalic acid in the mixed organic phase to obtain a mixed solution A, wherein the mixed organic phase is N,N- An organic mixture of dimethylformamide and acetic acid, the volume ratio of N,N-dimethylformamide and acetic acid in the mixed organic phase is 1:1, zirconium tetrachloride, hafnium tetrachloride, 2-amino-tere-phenylene The molar ratio of formic acid is 1:1:3, and the solid-to-liquid ratio g:mL of zirconium tetrachloride and mixed organic phase is 1:1;

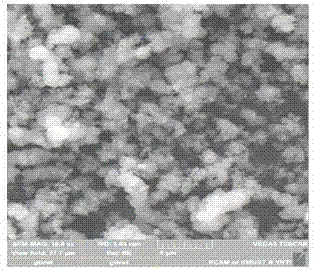

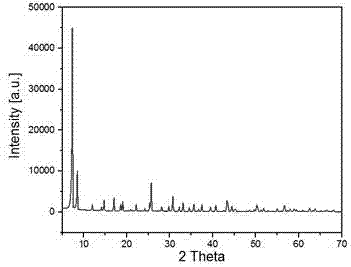

[0025] (2) Under the condition of stirring at 100°C, react the mixed solution A obtained in step (1) for 12 hours, filter, wash the solid with N,N-dimethylformamide, and dry it in vacuum to obtain the metal organic framework material UiO-66 (Zr,Hf)-(NH) 2 ;

[0026] The metal-organic framework materi...

Embodiment 2

[0028] Embodiment 2: A kind of preparation method of metal organic framework material, concrete steps are:

[0029] (1) At a temperature of 35°C, dissolve zirconium tetrachloride, hafnium tetrachloride, and 2-aminoterephthalic acid in the mixed organic phase to obtain a mixed solution A, wherein the mixed organic phase is N,N- An organic mixture of dimethylformamide and acetic acid, the volume ratio of N,N-dimethylformamide and acetic acid in the mixed organic phase is 1:2, zirconium tetrachloride, hafnium tetrachloride, 2-amino-tere-phenylene The molar ratio of formic acid is 1:2:6, and the solid-to-liquid ratio g:mL of zirconium tetrachloride and mixed organic phase is 2:1;

[0030] (2) Under the condition of stirring at a temperature of 110°C, the mixed solution A obtained in step (1) was reacted for 18 hours, filtered, washed with N,N-dimethylformamide, and dried in vacuum to obtain the metal organic framework material UiO-66 (Zr,Hf)-(NH) 2 ;

[0031] The metal-organic ...

Embodiment 3

[0032] Embodiment 3: A kind of preparation method of metal organic framework material, concrete steps are:

[0033] (1) Dissolve zirconium tetrachloride, hafnium tetrachloride and 2-aminoterephthalic acid in the mixed organic phase at a temperature of 30°C to obtain a mixed solution A, wherein the mixed organic phase is N,N- An organic mixture of dimethylformamide and acetic acid, the volume ratio of N,N-dimethylformamide and acetic acid in the mixed organic phase is 1:3, zirconium tetrachloride, hafnium tetrachloride, 2-amino-tere-phenylene The molar ratio of formic acid is 1:3:9, and the solid-to-liquid ratio g:mL of zirconium tetrachloride and mixed organic phase is 3:1;

[0034] (2) Under the condition of stirring at 120°C, react the mixed solution A obtained in step (1) for 24 hours, filter, wash the solid with N,N-dimethylformamide, and dry it in vacuum to obtain the metal organic framework material UiO-66 (Zr,Hf)-(NH) 2 ;

[0035] The metal-organic framework material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum adsorption capacity | aaaaa | aaaaa |

| Maximum adsorption capacity | aaaaa | aaaaa |

| Maximum adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com