Kiln device for producing mineral wool or rock wool by using high-temperature hot slag

A kiln and warming technology, applied in furnaces, waste heat treatment, furnace components, etc., can solve the problems of uncontrollable liquid level fluctuations, unstable product quality, high comprehensive cost, etc., and achieve the promotion of stability control, no exhaust gas emissions, The effect of guaranteeing uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

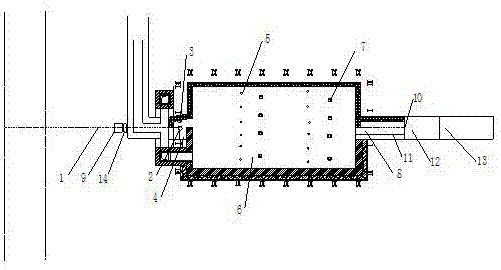

[0019] Such as figure 1 As shown, a kiln device for producing mineral wool or rock wool by using high-temperature hot slag in an embodiment of the present invention includes a hot flow slag ditch 1, a main feeding device 2, a mixing device 4, an electrode assembly 5, a kiln 6, a combustion device, bubbling device 7 and channel 8. One end of the hot flow slag ditch 1 is connected to the feed port of the kiln 6 , and the mixing device 4 is located inside the kiln 6 and communicated with the feed port of the kiln 6 . The outlet of the mixing device 4 communicates with the inner cavity of the kiln 6 . The main feeding device 2 is fixedly connected to the main feeding port of the kiln 6 . The combustion device is connected to the wall of the kiln 6 . The electrode assembly 5 is fixedly connected to the bottom of the furnac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com