Method for synthesizing black phosphate on carbon paper by one-step method and application of method

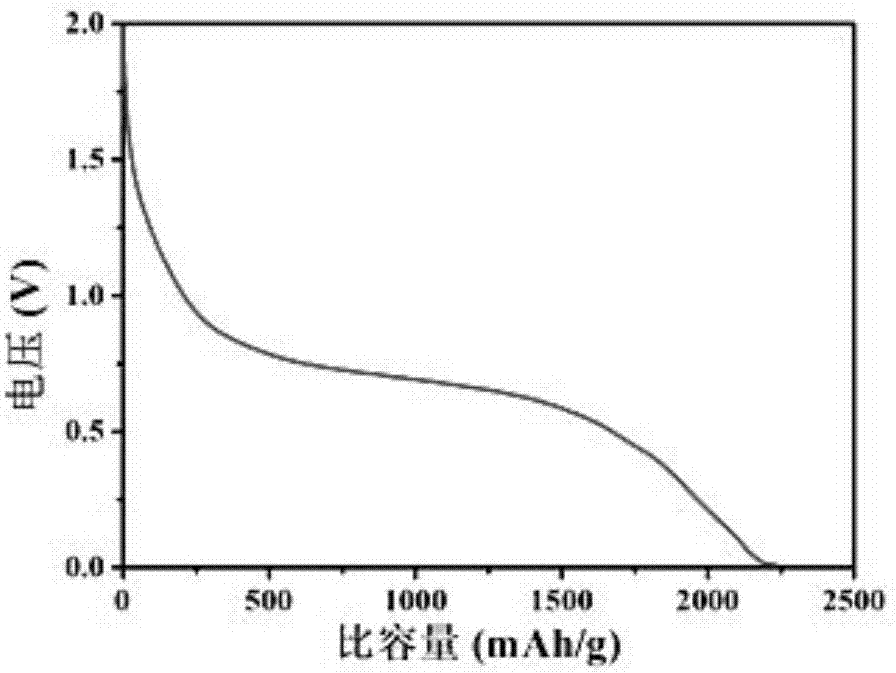

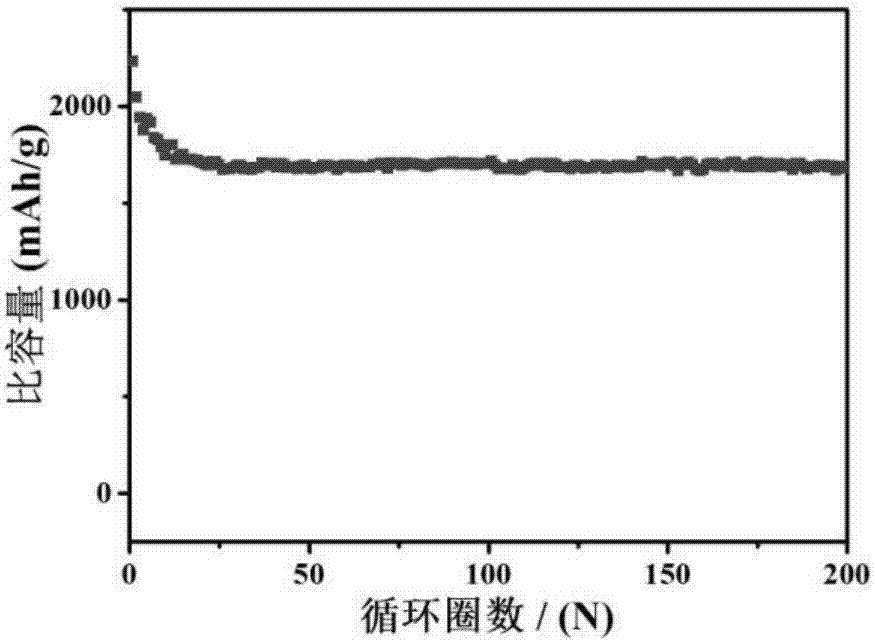

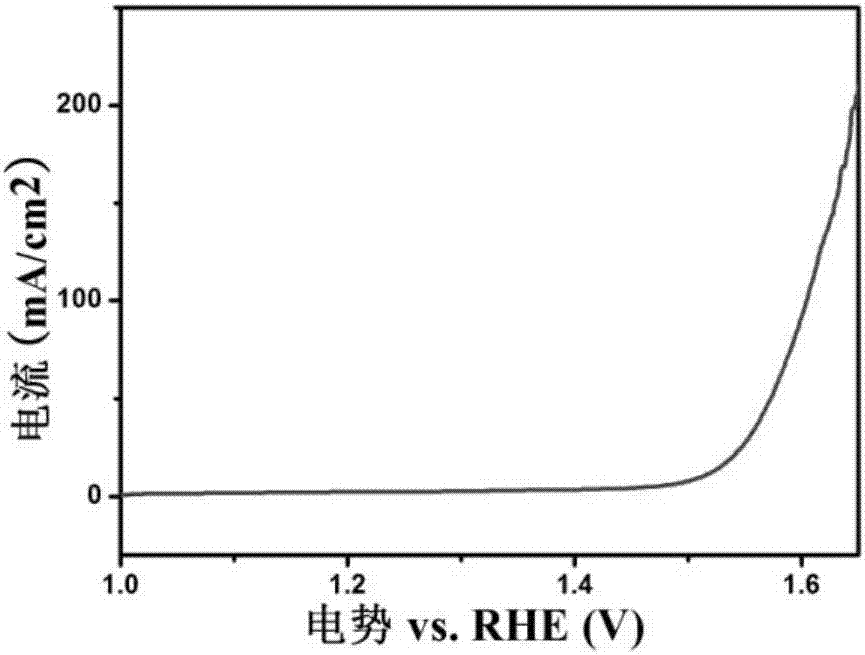

A technology of carbon paper and black phosphorus, applied in chemical instruments and methods, electrical components, electrochemical generators, etc., can solve the problems of high catalyst, low output, environmental pollution, etc., and achieve good electrochemical performance, small particles, good reversible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A method and application thereof for synthesizing black phosphorus on carbon paper in one step, specifically comprising the following steps:

[0024] S1. Weigh 5.0g of red phosphorus and put it evenly into the quartz boat, then put the quartz boat into the tube furnace, and then put the argon protective gas into the tube furnace; raise the temperature of the tube furnace to 180°C at a uniform speed, and heat 4h, carry out annealing treatment;

[0025] S2, after the annealing is completed, the annealed sample is prepared, and it is cooled to room temperature for subsequent use;

[0026] S3. Transfer the sample of S2 to a mortar and grind it for 40 minutes with a grinder to prepare the required precursor red phosphorus for later use;

[0027] S4. Weigh 0.5g of the precursor red phosphorus prepared in S3, put it evenly into the quartz boat, put the blank carbon paper on the quartz boat, and then transfer it to the middle of the tube furnace;

[0028] S5. Pass the protect...

Embodiment 2

[0031] A method and application thereof for synthesizing black phosphorus on carbon paper in one step, specifically comprising the following steps:

[0032]S1. Weigh 4.0g of red phosphorus and put it into the quartz boat evenly, then put the quartz boat into the tube furnace, and then put the argon protective gas into the tube furnace; raise the temperature of the tube furnace to 180°C at a uniform speed, and heat 2h, carry out annealing treatment;

[0033] S2, after the annealing is completed, the annealed sample is prepared, and it is cooled to room temperature for subsequent use;

[0034] S3, transfer the sample of S2 to a mortar and grind it for 20 minutes with a grinder to prepare the required precursor red phosphorus for later use;

[0035] S4. Weigh 0.4g of the precursor red phosphorus prepared in S3, put it evenly into the quartz boat, put the blank carbon paper on the quartz boat, and then transfer it to the middle of the tube furnace;

[0036] S5. Pass the protecti...

Embodiment 3

[0038] A method and application thereof for synthesizing black phosphorus on carbon paper in one step, specifically comprising the following steps:

[0039] S1. Weigh 6.0g of red phosphorus and put it into the quartz boat evenly, then put the quartz boat into the tube furnace, and then put the argon protective gas into the tube furnace; raise the temperature of the tube furnace to 250°C at a uniform speed, and heat 4h, carry out annealing treatment;

[0040] S2, after the annealing is completed, the annealed sample is prepared, and it is cooled to room temperature for subsequent use;

[0041] S3, transfer the sample of S2 to a mortar and grind it for 60 minutes with a grinder to prepare the required precursor red phosphorus for later use;

[0042] S4. Weigh 0.4g of the precursor red phosphorus prepared in S3, put it evenly into the quartz boat, put the blank carbon paper on the quartz boat, and then transfer it to the middle of the tube furnace;

[0043] S5. Pass the protect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| First discharge specific capacity | aaaaa | aaaaa |

| Specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com