A kind of rhenium selenium sulfide composite two-dimensional material, preparation method and application thereof

A two-dimensional material, rhenium sulfide technology, applied in chemical instruments and methods, catalyst activation/preparation, chemical/physical processes, etc., can solve the problems of inability to expose active sites, catalytic performance needs to be improved, and small active surface area. Achieve the effect of improving electrocatalytic performance, better catalytic performance and simple process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] This embodiment provides a rhenium selenium sulfide composite two-dimensional material (ReSe x S 2-x / CFP) preparation method, it comprises the steps:

[0029] (a) Take 0.1mmol ammonium perrhenate powder (NH 4 ReO 4 ) and thiourea (0.05mmol) were placed in 25ml DMF, and ultrasonically dissolved to form the first solution;

[0030] (b) Get 0.2mmol selenium powder and place it in 5ml hydrazine hydrate, and get the second solution after dissolving;

[0031] (c) After mixing the first solution and the second solution, pour the substrate (a piece of carbon paper of 1 cm × 3.5 cm, referred to as CFP, and place the carbon paper in acetone and ethanol for ultrasonic cleaning for 15 minutes each, After drying, put it into a 50mL polytetrafluoroethylene liner, leaning against the inner wall of the reactor), then put the inner tank into a stainless steel reactor, tighten the lid of the reactor, and place it in an oven at 200 ℃ for 30 hours; after the reaction is finished and ...

Embodiment 2

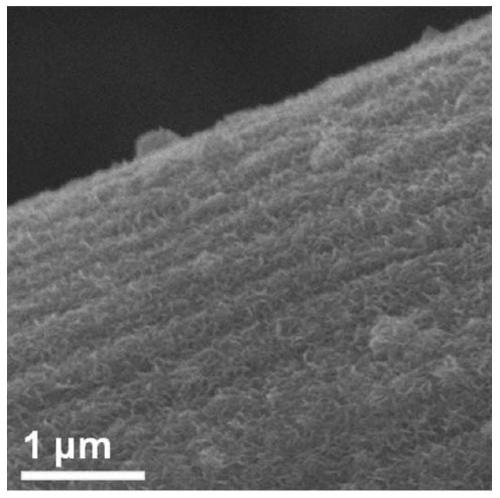

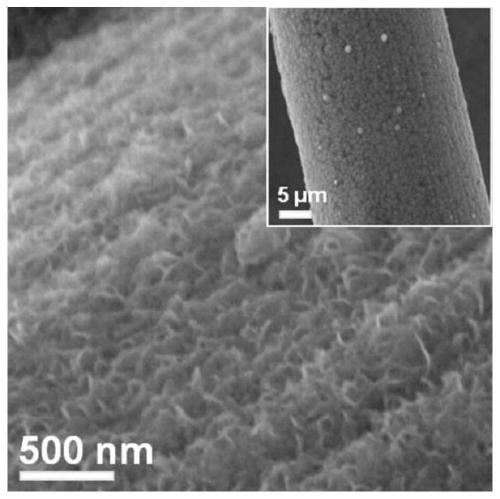

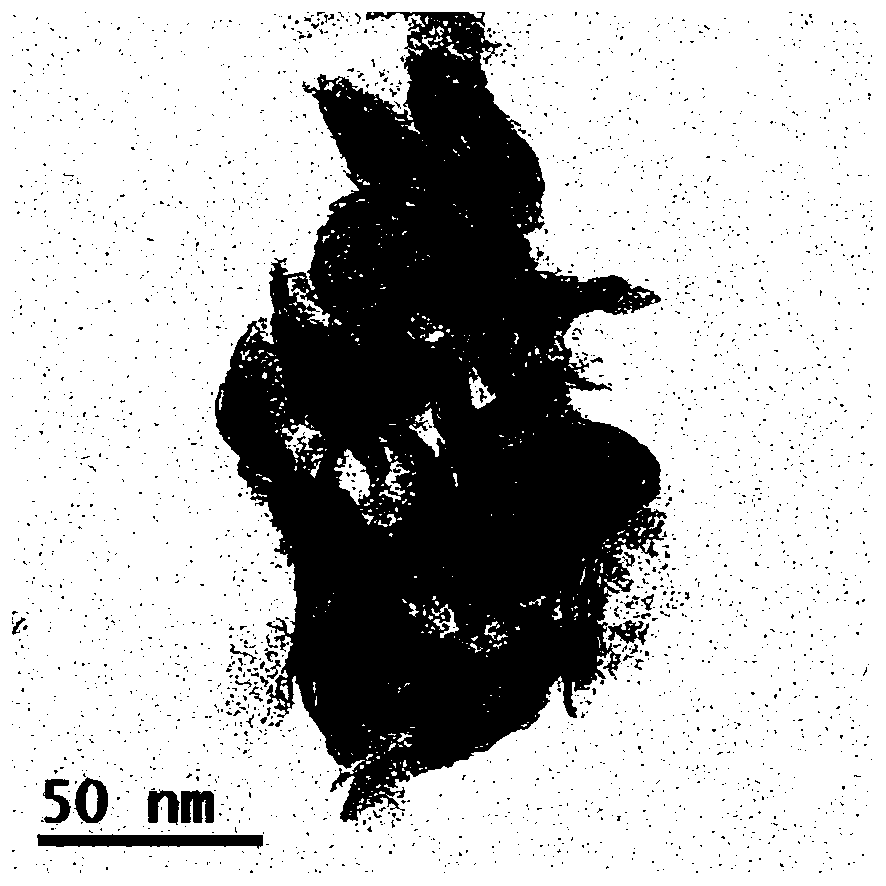

[0033] This embodiment provides a rhenium selenium sulfide composite two-dimensional material (ReSe x S 2-x / CFP) preparation method, which is basically the same as in Example 1, except that 0.1 mmol of thiourea is added in step (a), and the resulting product is expressed as ReSe by EDX element ratio result 1.78 S 0.22 / CFP, its SEM picture is as follows figure 2 As shown, the TEM image is shown in image 3 Shown, and the XRD curve is listed in such as Figure 4 middle.

Embodiment 3

[0035] This embodiment provides a rhenium selenium sulfide composite two-dimensional material (ReSe x S 2-x / CFP) preparation method, which is basically the same as that in Example 1, except that 0.2mmol of thiourea was added in step (a), and the product obtained was expressed as ReSe by EDX element ratio result 1.66 S 0.34 / CFP, its XRD curve is listed as Figure 4 middle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com