MnS/carbon composite material with sulfur defect as well as preparation method and application of MnS/carbon composite material

A carbon composite material and defect technology, applied in the direction of structural parts, electrical components, battery electrodes, etc., can solve the problems of large volume change, low restrictions on the application of lithium battery anode materials, low battery cycle life, etc., to improve electronic conductivity, good Electrochemical performance, the effect of improving electrochemical activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

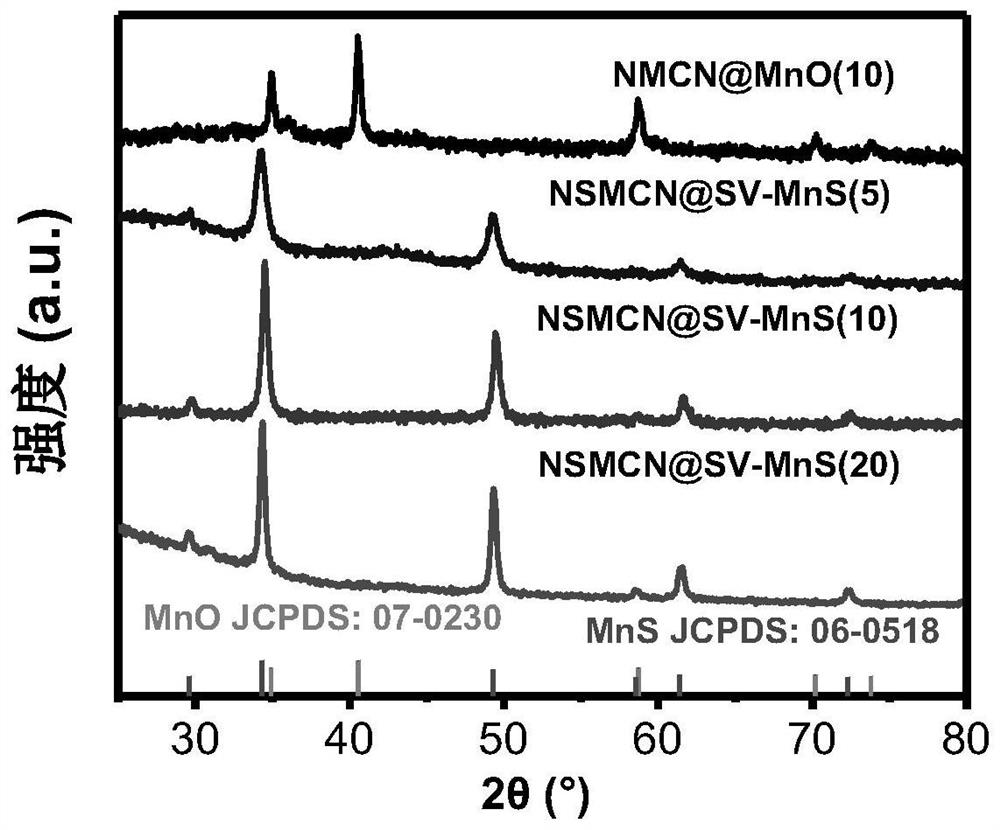

[0027] First, 10 mg of nitrogen-doped porous carbon spheres were ultrasonically dispersed into 20 mL of water, followed by a certain amount of KMnO 4 (5-20 mg) dissolved therein. After this, the dispersion was transferred to a 50 mL Teflon-lined autoclave for hydrothermal reaction at 140 °C for 1 h. After centrifugation and washing, the obtained solid was heated to 700 °C for 2 h at a heating rate of 5 °C / min and calcined to obtain NMCN@MnO(x) (x=5, 10, 20) nanospheres.

Embodiment 2

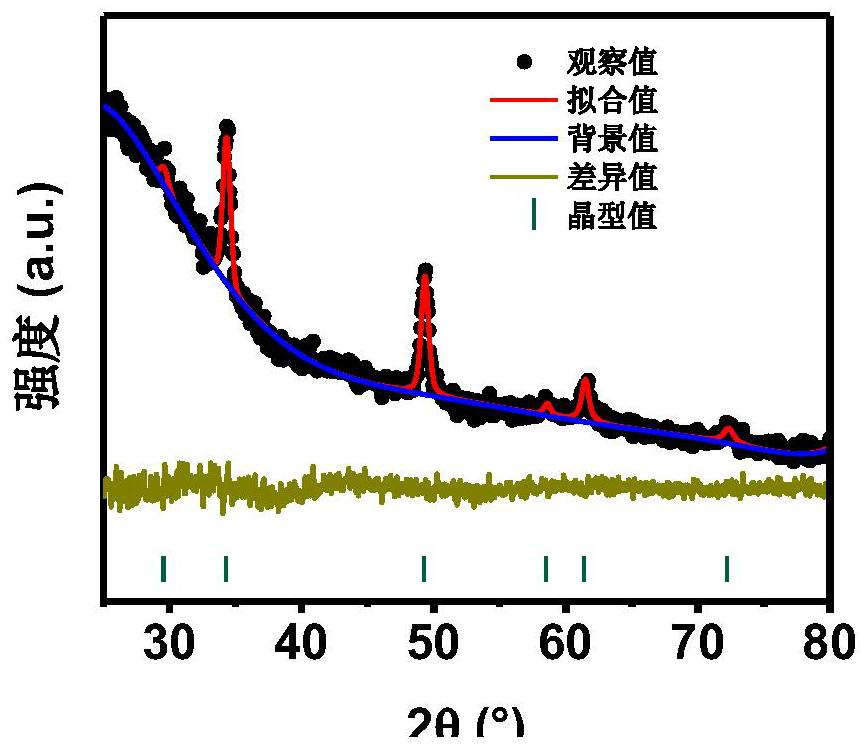

[0029] The NMCN@MnO and sublimed sulfur were thoroughly mixed in a mass ratio of 1:1.5 and placed in a corundum boat. Then, put the corundum boat into the tube furnace, in N 2 The temperature was raised to 400 °C for 5 h at a heating rate of 2 °C / min under the atmosphere to realize the conversion of MnO to MnS. Finally, the calcined solid is washed with carbon disulfide to remove residual sulfur to obtain the desired product. Various samples prepared in this case can be represented by the general formula NSMCN@SV-MnS(x), where x represents KMnO 4 The amount of addition (5-20mg).

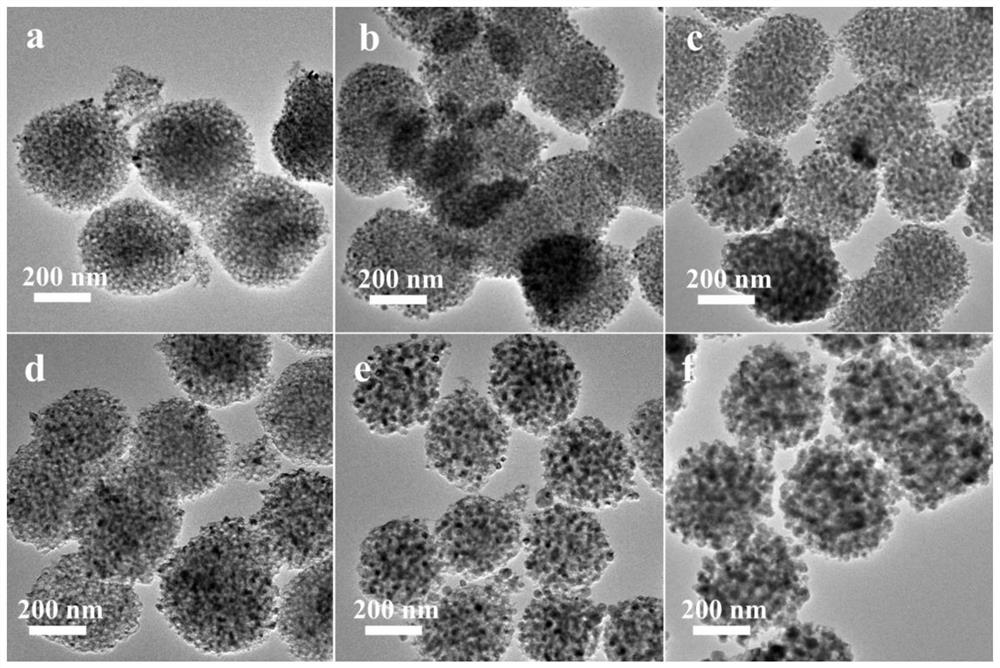

[0030] like figure 1 The NMCN@MnO(x) materials prepared for Examples 1 and 2 (a, b, c represent x=5, 10, 20, respectively) and NSMCN@SV-MnS(x) (d, e, f represent x, respectively) =5, 10, 20) TEM images. It can be seen from the figure that both the morphologies of the NMCN@MnO(x) material and NSMCN@SV-MnS(x) maintain uniform particles within the porous sphere, and with the increase of the precurs...

Embodiment 3

[0043] 80% of the samples (NSMCN@SV-MnS(x) or NMCN@MnO(10) materials), 10% conductive carbon black were dispersed into 10% PVDF in NMP solution. It was evenly coated on copper foil, and after drying in a vacuum oven for 12 hours, it was punched into a circular electrode sheet with a diameter of 12 mm. The electrode sheet loaded with active material was used as the working electrode, and the copper foil was used as the counter electrode to form a button battery. Electrolyte (1M LiPF6, the solvent is ethylene carbonate / dimethyl carbonate / ethyl methyl carbonate mixed solvent (EC / DEC / EMC) with a volume ratio of 1:1:1), the battery is assembled in an argon-filled glove carried out in the box. The charge and discharge test of the battery is carried out on the ARBIN test system.

[0044] from Figure 6-7 It can be seen from the figure that the electrochemical performance of the manganese sulfide carbon composite is better than that of the manganese oxide carbon composite under the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com