Preparation process of potassium perchlorate

A preparation process, potassium perchlorate technology, applied in the direction of perchloric acid, perchlorate, etc., can solve the problems of high process cost and low purity of finished products, and achieve the effect of high purity and wide source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

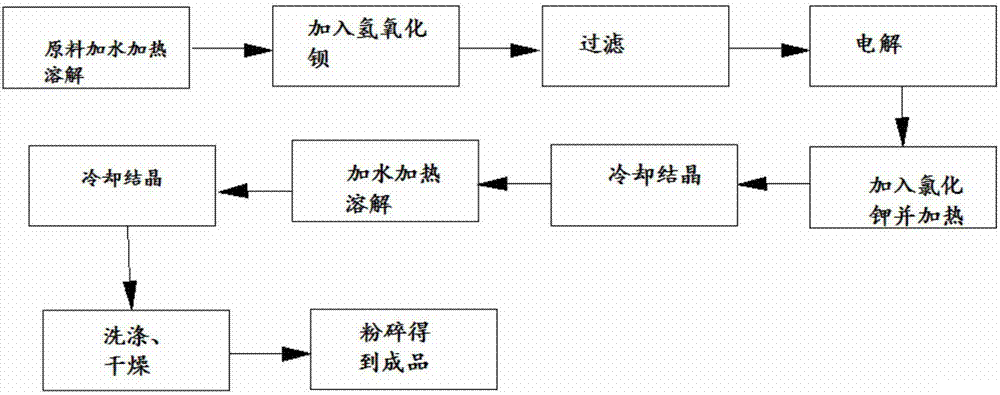

[0014] Reference figure 1 , The preparation process of potassium perchlorate of the present invention includes the following steps:

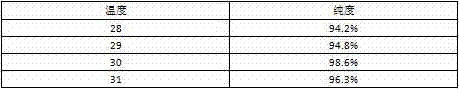

[0015] Heat one part of industrial sodium chlorate and dissolve in one part of water, add barium hydroxide solution until the solution no longer produces precipitation, remove impurities such as chromate and sulfate in the solution, filter to remove insoluble substances in the solution, and then place the resulting filtrate Put it into the electrolytic tank for electrolysis. After 20 minutes of electrolysis, add the equivalent mass of saturated potassium chloride solution to the obtained electrolyte, and stir and heat it. When the solution no longer precipitates solids, place the solution in a new container and place it in a ventilated place. Perform cooling and crystallization, keep the temperature at 28 degrees, stop crystallization when 1 / 5 of the solution is left, heat the obtained crystals with distilled water to dissolve, and then continue to...

Embodiment 2

[0017] Reference figure 1 , The preparation process of potassium perchlorate of the present invention includes the following steps:

[0018] Dissolve one part of industrial sodium chlorate in one part of water by heating, add barium hydroxide solution until the solution no longer precipitates, remove impurities such as chromate and sulfate in the solution, filter to remove insoluble substances in the solution, and then place the resulting filtrate Enter the electrolytic cell for electrolysis. After 20 minutes of electrolysis, add the equivalent mass of saturated potassium chloride solution to the resulting electrolyte, and stir and heat it. When the solution no longer precipitates solids, place the solution in a new container and place it in a ventilated place. Perform cooling and crystallization, keep the temperature at 29 degrees, stop crystallization when 1 / 5 of the solution is left, heat the obtained crystals with distilled water to dissolve, and then continue to cool and cry...

Embodiment 3

[0020] Reference figure 1 , The preparation process of potassium perchlorate of the present invention includes the following steps:

[0021] Heat one part of industrial sodium chlorate and dissolve in one part of water, add barium hydroxide solution until the solution no longer produces precipitation, remove impurities such as chromate and sulfate in the solution, filter to remove insoluble substances in the solution, and then place the resulting filtrate Put it into the electrolytic tank for electrolysis. After 20 minutes of electrolysis, add the equivalent mass of saturated potassium chloride solution to the obtained electrolyte, and stir and heat it. When the solution no longer precipitates solids, place the solution in a new container and place it in a ventilated place. Perform cooling and crystallization, keep the temperature at 30 degrees, stop crystallization when 1 / 5 of the solution is left, heat the obtained crystals with distilled water to dissolve, and then continue to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com